Toyota’s journey in the automotive world is a remarkable tale of innovation and perseverance. What began as a division of a loom company in the 1930s has transformed into one of the world’s largest automobile manufacturers. The Toyota story showcases how consistent quality, fuel-efficient manufacturing, and innovative production systems enabled a small Japanese company to compete with established giants like Ford and GM.

From its humble beginnings in the Japanese weaving industry, Toyota has evolved through decades of challenges and triumphs. The company’s founder, Sakichi Toyoda, started with the invention of an automatic loom, before the company pivoted to automobile production. This transition from “looms to zooms” represents one of the most successful business transformations in industrial history.

Key Takeaways

- Toyota evolved from a loom manufacturer to become a global automotive leader through consistent quality and innovative production methods.

- The Toyota Production System revolutionized manufacturing worldwide with its focus on efficiency, waste reduction, and continuous improvement.

- Toyota’s commitment to sustainability has positioned it as a pioneer in hybrid and electric vehicle technology, shaping the future of transportation.

The Beginnings of Toyota

Toyota’s journey began in the Japanese textile industry before evolving into the automotive giant we know today. The company’s foundation rests on innovation, quality, and a vision that transformed from looms to vehicles.

Sakichi Toyoda and the Toyoda Automatic Loom Works

Sakichi Toyoda, often called the “King of Japanese Inventors,” began his entrepreneurial journey in the textile industry in the late 19th century. Born in 1867, he revolutionized Japan’s weaving industry with his automatic loom inventions.

In 1926, Sakichi created the Toyoda Automatic Loom Works, which featured his groundbreaking automatic loom that could detect broken threads and shut down automatically. This innovation embodied the concept of “jidoka” (automation with a human touch), which later became a core principle of Toyota’s manufacturing philosophy.

The automatic loom was so impressive that in 1929, Sakichi sold the patent rights to a British company for £100,000. This significant sum would later fund Toyota’s move into automobile manufacturing.

Kiichiro Toyoda and the Birth of an Automotive Division

Kiichiro Toyoda, Sakichi’s son, began Toyota’s journey in the automobile industry in 1933. After studying mechanical engineering and visiting automobile factories in Europe and America, Kiichiro convinced his family to invest in automotive technology.

In 1933, he established an automotive department within Toyoda Automatic Loom Works. His team developed their first engine in 1934, and by 1935, they had completed their first prototype passenger car, the Model A1.

The Toyota Motor Company was officially established as an independent entity in 1937. Kiichiro made a bold decision to change the spelling from “Toyoda” to “Toyota” for several reasons:

- The name “Toyota” required eight brush strokes to write in Japanese, considered a lucky number

- The new name sounded clearer in Japanese pronunciation

- It created separation between the family’s personal and business identities

Under Kiichiro’s leadership, Toyota quickly made their mark in the auto industry with early production focused on simple, reliable vehicles designed for Japanese roads and conditions.

Building the Foundation

Toyota’s journey from a textile machinery company to automotive giant was marked by bold innovation and careful planning. The transformation showcases how Toyota built upon its manufacturing expertise to create a foundation for future success.

Creation of Toyota Motor Co

The story of Toyota Motor Company begins with Kiichiro Toyoda, son of Sakichi Toyoda who founded Toyoda Automatic Loom Works. In 1933, Kiichiro established an automobile department within his father’s company, focusing on car production. His vision was to develop vehicles specifically for the Japanese market.

By 1937, this department had grown enough to become an independent company – Toyota Motor Co., Ltd. The name changed from “Toyoda” to “Toyota” because it required fewer brush strokes to write in Japanese and was considered more aesthetically pleasing.

The company’s initial capital was 12 million yen, and its headquarters were established in Koromo (now Toyota City), Japan. This marked the official birth of what would become one of the world’s largest automotive manufacturers.

Innovations in Manufacturing: From Textiles to Automobiles

Toyota’s manufacturing excellence has roots in its textile industry origins. Sakichi Toyoda’s automatic loom featured an innovative mechanism that would stop the machine when a thread broke – an early version of the “jidoka” (automation with human intelligence) concept that later defined Toyota’s production system.

Kiichiro Toyoda applied these principles to automobile manufacturing, developing the revolutionary Just-in-Time production system. This approach minimized waste by producing only what was needed, when needed, and in the amount needed.

The company studied American automobile production techniques, particularly Ford’s assembly line methods. However, instead of simply copying these approaches, Toyota adapted them to suit Japanese conditions and limited resources after World War II. This led to the creation of the Toyota Production System, which emphasized efficiency and waste elimination.

The Model SA and Early Developments

In 1947, Toyota released the Model SA, its first passenger car developed entirely after World War II. This small sedan, nicknamed “Toyopet,” featured:

- A 995cc, 27-horsepower engine

- A top speed of 54 mph (87 km/h)

- Seating for up to five passengers

The Model SA represented Toyota’s commitment to creating vehicles suited specifically for Japanese roads and conditions. Its compact size and fuel efficiency addressed the needs of post-war Japan, where resources were scarce.

Before that, Toyota had focused primarily on truck production to support Japan’s military efforts. The shift to passenger cars marked a pivotal moment in the company’s history. Engineers worked tirelessly to develop new technologies despite limited resources in post-war Japan.

This early period established Toyota’s reputation for reliable, practical vehicles that would later help the company expand globally.

Strategic Growth and World War II Impact

Toyota’s development as a company took a significant turn during World War II. The war altered production priorities and established important governmental relationships that would shape the company’s future trajectory.

Automobile Production during the War

When World War II began, Toyota’s manufacturing focus shifted dramatically. The company suspended production of passenger cars and redirected its resources toward truck manufacturing to support Japan’s war efforts. This strategic pivot was necessary for survival during a time of national crisis.

Toyota’s facilities were dedicated to military production needs. The company produced trucks and other vehicles essential for military transportation. This period tested Toyota’s manufacturing capabilities and adaptability.

The war years were challenging but provided valuable experience in efficient production methods. Despite material shortages and difficult conditions, Toyota engineers developed innovative solutions that would later influence their manufacturing philosophy.

Relationship with the Japanese Government

During World War II, Toyota developed a close working relationship with the Japanese government. As a major industrial manufacturer, the company became vital to Japan’s wartime economy and received direct government oversight.

This partnership established patterns of cooperation that continued after the war. The Japanese government recognized Toyota’s manufacturing potential and provided support for its recovery and growth when hostilities ended.

After the war, Toyota benefited from Japan’s alliance with the United States, which created opportunities to learn from American manufacturing techniques. The government facilitated these knowledge transfers as part of Japan’s industrial rebuilding strategy.

These government connections helped Toyota secure necessary resources during post-war scarcity. The resource constraints faced in post-war Japan pushed Toyota to develop its famous Toyota Production System (TPS), which emphasized efficiency and waste reduction.

Technological Advancements and Toyota Production System

Toyota revolutionized manufacturing with innovative systems that changed the automotive industry forever. The company developed methods that reduced waste, improved quality, and maximized efficiency in ways that competitors struggled to match.

Lean Manufacturing and Just-In-Time

Toyota’s approach to manufacturing was transformed in the 1950s when it introduced Lean Manufacturing and Just-In-Time production. These concepts fundamentally changed how cars were built worldwide.

The Just-In-Time system eliminated waste by ensuring parts arrived exactly when needed in production. This reduced storage costs and inventory while improving efficiency. Rather than stockpiling components, Toyota coordinated with suppliers to deliver parts precisely when required.

Lean Manufacturing focused on removing all non-value-adding activities from the production process. This meant identifying and eliminating seven types of waste:

- Overproduction

- Waiting time

- Transportation

- Over-processing

- Inventory

- Motion

- Defects

This approach helped Toyota build cars more efficiently and with less wasted resources than its competitors.

Quality and Reliability Through TPS

The Toyota Production System (TPS) established quality and reliability as core values. The system was built on two main pillars: “Jidoka” (automation with a human touch) and Just-In-Time production.

Jidoka empowered workers to stop production immediately if they spotted a defect. This prevented faulty parts from moving further down the assembly line. The philosophy valued getting things right the first time rather than fixing mistakes later.

TPS incorporated the concept of “Kaizen” or continuous improvement. Workers at all levels were encouraged to suggest small, incremental improvements to processes. These small changes added up to significant quality improvements over time.

The focus on quality through TPS helped Toyota vehicles become known for exceptional reliability. This reputation became one of Toyota’s strongest competitive advantages in global markets.

Taiichi Ohno and Process Innovations

Taiichi Ohno, often called the father of TPS, developed many of Toyota’s revolutionary production concepts. After visiting Ford’s factories in the 1950s, Ohno identified opportunities to improve on mass production methods.

Ohno introduced the “pull” system in manufacturing. Unlike traditional “push” systems where production moved at a preset pace, Toyota’s pull system produced vehicles based on actual customer demand. This reduced waste and improved efficiency.

He also developed the “5 Whys” technique for problem-solving. This method involved asking “why” five times to identify the root cause of any production issue rather than addressing symptoms.

Another Ohno innovation was the “andon cord,” which allowed any worker to stop the production line if they noticed a quality problem. This democratized quality control and made every employee responsible for the final product’s reliability.

Automobiles that Defined Generations

Toyota’s journey to global dominance was propelled by several iconic vehicles that captured hearts across different markets and eras. These automobiles perfectly balanced innovation, reliability, and consumer needs.

The Corolla: A Global Phenomenon

The Toyota Corolla, launched in 1966, has become the world’s first mass-produced hybrid car and holds the title of best-selling car in automotive history. With over 50 million units sold across 12 generations, the Corolla revolutionized personal transportation worldwide.

The Corolla’s success stems from its perfect balance of affordability, reliability, and fuel efficiency. This compact car helped Toyota penetrate international markets, particularly in North America and Europe during the 1970s oil crisis.

In many countries, the Corolla became synonymous with dependable transportation. Its consistent evolution kept it relevant through changing consumer preferences and technological advancements.

Toyota Crown and Land Cruiser: Building a Reputation

The Toyota Crown, introduced in 1955, established Toyota as a serious contender in the luxury segment. As Toyota’s first export to the United States, the Crown demonstrated the company’s ability to create upscale vehicles with sophisticated engineering.

The Land Cruiser, introduced in 1951, became legendary for its unmatched durability and off-road capability. Originally designed for military use, it evolved into a beloved civilian vehicle that conquered terrains from African deserts to Australian outback.

Both vehicles showcased Toyota’s versatility in the automobile industry. The Crown’s elegant design and comfort features appealed to executives and officials, while the Land Cruiser’s rugged reliability made it essential for challenging environments.

Breaking New Ground with Hybrids and Electric Vehicles

Toyota revolutionized the automotive industry with its commitment to sustainable transportation technologies. The company’s foresight in developing alternative fuel vehicles has positioned it as a leader in eco-friendly mobility solutions.

Toyota Prius: Pioneering Hybrid Technology

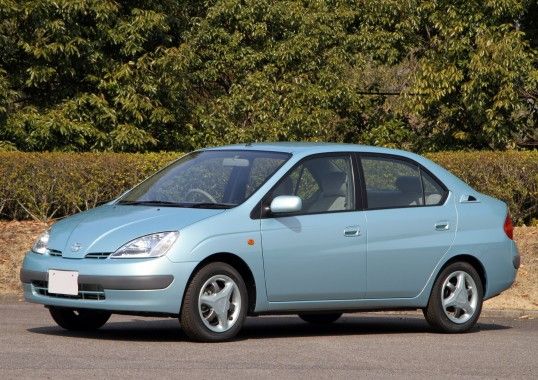

The Toyota Prius made history in 1997 as the world’s first mass-produced hybrid vehicle. This groundbreaking car combined a gasoline engine with an electric motor, drastically reducing emissions and fuel consumption.

The Prius wasn’t just innovative technology—it became a cultural icon. Its distinctive shape and green credentials made it popular among environmentally conscious consumers and celebrities alike.

Over four generations, Toyota continuously improved the Prius’s hybrid system. The company’s Hybrid Synergy Drive technology became more efficient and powerful with each iteration.

By 2022, Toyota had sold more than 15 million hybrid electric vehicles worldwide, with the Prius accounting for a significant portion of these sales.

Diversification into Electric Mobility

While Toyota built its reputation on hybrid technology, the company has been working with alternative fuel sources for three decades. Their approach to electric vehicles has been methodical and strategic.

Initially, Toyota seemed hesitant to fully embrace battery electric vehicles (BEVs), preferring to focus on hybrid technology and hydrogen fuel cells.

In 2021, the company announced a significant shift with plans to introduce 30 electric vehicle models by 2030. The bZ4X SUV became Toyota’s first modern all-electric vehicle for global markets.

Toyota’s electric mobility strategy extends beyond personal vehicles. The company has invested in autonomous vehicle technology and mobility services, positioning itself for the future of transportation.

This diversified approach reflects Toyota’s philosophy of offering multiple solutions to meet different market needs and infrastructure capabilities around the world.

The Global Expansion Era

Toyota’s transition from a Japanese manufacturer to a global automotive powerhouse occurred through strategic international growth and brand diversification. The company skillfully navigated foreign markets while developing premium offerings that would cement its worldwide reputation.

Export Success and U.S. Market Entry

Toyota began its international journey in the 1950s, but the 1960s marked the start of serious global ambitions. By 1962, Toyota had produced its millionth vehicle, signaling readiness for worldwide expansion. The company launched Toyota to superstar status on the global stage during this transformative era.

The oil crisis of the 1970s created an unexpected opportunity. American consumers, facing fuel shortages, turned to Toyota’s smaller, fuel-efficient vehicles. The Corona and Corolla models became especially popular for their reliability and economy.

Toyota established its first U.S. sales headquarters in 1957, but significant market penetration came in the 1970s-1980s. By 1975, Toyota surpassed Volkswagen as the top import brand in America.

To overcome trade tensions, Toyota made a bold move in 1986 by opening its first U.S. manufacturing plant in Georgetown, Kentucky. This “build where you sell” strategy helped Toyota reduce political pressure while creating American jobs.

Development of Lexus Brand and Luxury Market Penetration

In the 1980s, Toyota recognized an untapped opportunity in the luxury car market. Rather than elevating the Toyota brand, the company made a strategic decision to create an entirely new luxury division.

After investing over $1 billion in development, Lexus was born in 1989 with the launch of two models: the LS 400 sedan and ES 250. The LS 400 stunned the automotive world with its exceptional quality, performance, and competitive pricing against established European luxury brands.

Lexus quickly gained recognition for its superior quality and customer service excellence. The brand’s commitment to the “pursuit of perfection” resonated with luxury buyers seeking alternatives to traditional German and American luxury vehicles.

By the mid-1990s, Lexus became America’s best-selling luxury import brand. This successful luxury market penetration demonstrated Toyota Motor Corporation’s ability to compete across all automotive segments, from economy to premium vehicles.

Toyota Today: Towards a Sustainable and Innovative Future

Toyota continues to shape the automotive landscape through its dual focus on sustainability and innovation. The company balances environmental responsibility with cutting-edge research that drives its global business strategy.

Commitment to Sustainability and Environment

Toyota has positioned itself as a leader in environmental stewardship with its commitment to sustainable mobility. The company introduced the groundbreaking Prius in 1997, which revolutionized the industry as the first mass-produced hybrid vehicle.

Today, Toyota’s Environmental Challenge 2050 aims for zero carbon emissions across all operations. This ambitious plan includes:

- Reducing vehicle CO2 emissions by 90%

- Achieving carbon neutrality in manufacturing

- Optimizing water usage in production facilities

- Establishing recycling-based systems for resources

Toyota has expanded its eco-friendly lineup with hydrogen fuel cell vehicles like the Mirai, demonstrating its multi-pathway approach to sustainability. The company recycles over 91% of materials in its manufacturing processes.

Continuous Improvement and Research & Development

Toyota’s philosophy of Kaizen (continuous improvement) remains central to its operations. The company invests approximately $9 billion annually in R&D, focusing on autonomous driving, connectivity, and alternative powertrains.

The Toyota Research Institute, established in 2016, spearheads research in artificial intelligence and robotics. Their work extends beyond vehicles to areas like assistive home technology for aging populations.

Toyota’s innovation centers span the globe with facilities in Japan, North America, and Europe. These centers develop technologies that enhance safety, efficiency, and user experience.

The company’s Connected Strategy aims to transform vehicles into platforms that integrate with broader mobility ecosystems. By 2030, Toyota plans to have over 70 electrified models globally, including 15 dedicated battery electric vehicles.

Corporate Culture and Leadership

Toyota’s success stems from its distinctive corporate philosophy and leadership approach. The company’s management principles have shaped its growth from a small Japanese loom maker to a global automotive powerhouse.

The Toyota Way and Cultural Tenets

The Toyota Way serves as the foundation of the company’s corporate culture. Established formally in 2001, this philosophy rests on two main pillars: continuous improvement and respect for people. These principles guide every aspect of Toyota’s operations.

Key elements of Toyota’s cultural tenets include:

- Kaizen (continuous improvement)

- Genchi Genbutsu (go and see for yourself)

- Challenge (maintaining a long-term vision)

- Teamwork (developing and respecting team members)

- Respect (building mutual trust)

Toyota’s culture emphasizes resilience and continuous improvement in all aspects of their business. The company values long-term thinking over short-term gains, making decisions that benefit the organization’s sustainability rather than quarterly profits.

Leadership Development and Global Influence

Toyota invests heavily in developing leaders who embody its cultural values. Future executives undergo extensive rotations through different departments and international assignments to gain comprehensive understanding of the business.

The company’s leadership philosophy centers on servant leadership, where managers support their teams rather than simply directing them. This approach helped Toyota pass Ford and become a dominant global manufacturer.

Toyota leaders are expected to be teachers who develop others. The company maintains a tradition where experienced employees mentor newer ones, passing down organizational knowledge and values.

Toyota’s leadership model has influenced global business practices beyond the automotive industry. Many organizations worldwide have adopted elements of Toyota’s management approach, particularly its emphasis on quality, efficiency, and respect for workers.

Frequently Asked Questions

Toyota’s journey from a small textile machinery company to a global automotive leader spans nearly a century of innovation, strategic expansion, and manufacturing excellence. These questions explore the key milestones and decisions that shaped this remarkable transformation.

What led to Toyota’s expansion into international markets?

Toyota’s international expansion began in the 1950s after careful market analysis and strategic planning. The company recognized that growth opportunities existed beyond Japan’s borders.

The first major overseas venture was in Brazil in 1958, followed by Thailand in 1962. However, Toyota’s entry into the American market in 1957 marked the most significant step in its global journey.

The 1973 oil crisis actually accelerated Toyota’s international growth as consumers sought fuel-efficient alternatives to American cars. Toyota’s reputation for reliability and efficiency helped it quickly make their mark in the auto industry.

Who was responsible for developing the Toyota Production System, and what impact did it have?

Taiichi Ohno, a Toyota executive, developed the Toyota Production System (TPS) in the 1950s. He created this system after studying American supermarkets and Ford’s production methods.

The TPS revolutionized manufacturing with its focus on eliminating waste, continuous improvement (kaizen), and just-in-time production. These principles allowed Toyota to produce high-quality vehicles with fewer resources.

This system became so influential that manufacturers worldwide adopted its principles, often under the name “lean manufacturing.” The TPS remains one of Toyota’s most significant contributions to global business practices.

What was the original product manufactured by Toyota before it became a car company?

Toyota’s origins lie in the textile industry, not automobiles. Sakichi Toyoda, the company founder, invented the world’s first automatic loom in 1924.

The Toyoda Automatic Loom Works was established in 1926 to manufacture these revolutionary weaving machines. The company’s success in textile machinery provided the financial foundation for its later automotive ventures.

In 1933, Kiichiro Toyoda, Sakichi’s son, created a new division within the company dedicated to automobile production. The Japanese government had urged him to develop domestic vehicles, which eventually led to the complete transformation of the business.

What is the history and evolution of Toyota automobiles?

Toyota’s first prototype car, the A1, was completed in 1935, followed by the first production vehicle, the Model AA sedan in 1936. Early development focused on copying and improving American designs.

During World War II, Toyota focused on producing trucks for military use rather than passenger vehicles. After the war, the company struggled until the Korean War created demand for military vehicles.

The launch of the Crown in 1955 and the Corona in 1957 established Toyota’s reputation for reliability. The introduction of the Corolla in 1966 became a turning point, eventually making it the best-selling car model in history with over 50 million units sold.

In what year was Toyota Motor Corporation officially founded?

Toyota Motor Corporation was officially established on August 28, 1937. This marked the formal separation of the automotive division from Toyoda Automatic Loom Works.

Interestingly, the company name changed from “Toyoda” to “Toyota” when it was incorporated. The new name required eight brush strokes to write in Japanese (considered lucky) and created a cleaner sound.

The founding of the corporation came after several years of automotive research and development led by Kiichiro Toyoda, who became the first president of the new company.

What strategies has Toyota employed to become such a significant player in the global market?

Toyota’s global success stems from its unwavering commitment to quality and continuous improvement. The company pioneered the “build where you sell” approach, establishing manufacturing plants in key markets to reduce costs and adapt to local preferences.

Product diversification has been another key strategy, with Toyota offering vehicles across all market segments. From affordable compact cars to luxury Lexus models, the company serves customers at every price point.

Toyota has also demonstrated remarkable foresight in environmental innovation. The 1997 launch of the Prius, the world’s first mass-produced hybrid vehicle, established Toyota as a leader in sustainable transportation from humble beginnings to becoming a global leader in automotive technology.