In 1913, Henry Ford revolutionized manufacturing with the moving assembly line, cutting production time for the Model T by an impressive 75%. This innovation brought mobility and prosperity on an undreamed of scale through manufacturing efficiencies at prices average people could afford. The Model T changed how we think about transportation and made cars accessible to the masses.

A century later, Tesla has transformed automotive manufacturing once again by combining advanced automation with electric vehicle technology. While Ford’s assembly line focused on making identical cars quickly and cheaply, Tesla’s modern approach balances mass production with customization and sustainability. The evolution from the Model T to Tesla represents not just technological advancement but a fundamental shift in consumer values.

The automotive industry has come full circle in many ways. Ford’s Model T democratized transportation through affordable mass production, while Tesla is making sustainable transportation mainstream through innovative manufacturing. Both companies changed not just how cars are made, but also how people think about mobility and its impact on society.

Key Takeaways

- The Model T’s assembly line and Tesla’s automated factories represent two revolutionary shifts in mass production separated by 100 years.

- Electric vehicles have driven a second manufacturing revolution that balances efficiency with customization and sustainability.

- Consumer preferences have evolved from simply wanting affordable transportation to demanding vehicles that are both technologically advanced and environmentally responsible.

The Dawning of Mass Production

The early 1900s witnessed a revolutionary shift in manufacturing that forever changed how products were made and consumed. This transformation centered around the automotive industry, where innovative production methods dramatically reduced costs while increasing output.

Birth of the Model T

Henry Ford introduced the Model T in 1908, creating a vehicle specifically designed to be affordable for the average American. Before this breakthrough, automobiles were luxury items only accessible to the wealthy elite.

The Model T was intentionally designed with simplicity in mind. Ford focused on creating a car that was not only easy to manufacture but also easy to drive and repair.

Initially priced at $850 (about $25,000 in today’s money), the Model T’s price eventually dropped to $260 (around $4,000 today) as production methods improved. This dramatic price reduction made car ownership possible for middle-class families for the first time.

The vehicle ran on gasoline when most competitors were still experimenting with steam or electric power, helping establish the internal combustion engine as the industry standard.

Innovations in Manufacturing Process

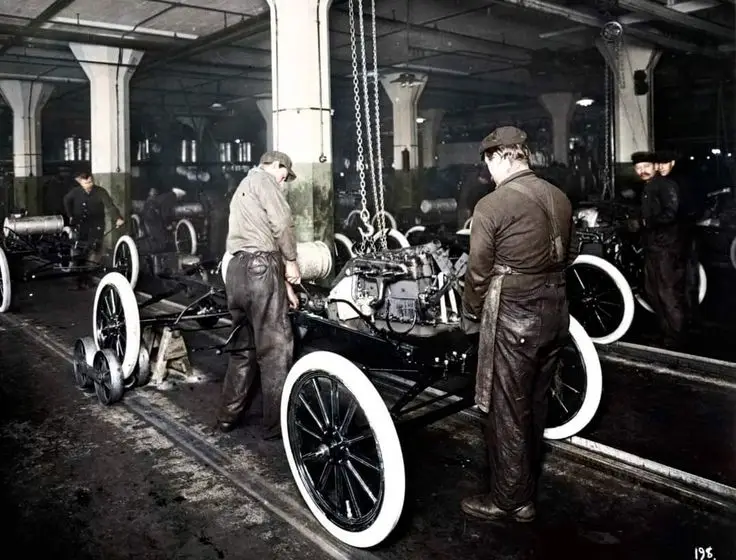

Ford’s greatest contribution wasn’t the car itself but how it was made. In 1913, Ford implemented the moving assembly line at his Highland Park factory, revolutionizing manufacturing.

Before the assembly line, skilled craftsmen built entire cars at stationary locations. Ford broke this process into simple, repeatable tasks performed by workers as vehicles moved past them on a conveyor system.

This innovation reduced the time to build a Model T chassis from 12.5 hours to just 1.5 hours. Production efficiency skyrocketed from 18,000 cars in 1909 to over 1 million by 1920.

Ford also pioneered the use of interchangeable parts, ensuring components were standardized and easily replaceable. This approach eliminated the need for custom-fitting parts, further speeding up production.

The assembly line concept quickly spread beyond automobiles to other industries, creating the foundation for modern mass production methods.

Impact on Traditional Automakers

The success of the Model T sent shockwaves through the automotive industry. Competitors initially dismissed Ford’s methods but soon realized they couldn’t compete with his pricing and production volumes.

Traditional automakers faced a difficult choice: adapt or perish. Many luxury manufacturers like Cadillac and Packard initially resisted mass production, believing it would compromise quality and craftsmanship.

However, the mass automobility enabled by the Model T created an entirely new market of middle-class consumers. Most manufacturers eventually adopted elements of Ford’s production techniques while attempting to maintain their brand identity.

General Motors under Alfred Sloan developed a strategic response by creating a range of vehicles at different price points, establishing the concept of annual model changes to encourage repeat purchases.

By the 1920s, independent carmakers who couldn’t transition to mass production methods began disappearing, consolidating the industry around larger manufacturers who embraced the new manufacturing paradigm.

Elevation of Automobile Standards

As cars evolved from basic transportation to complex machines, the standards for manufacturing and quality rose dramatically. This transformation created new industry structures and efficiency models that forever changed how vehicles are made.

Emergence of Original Equipment Manufacturers (OEMs)

The success of the Model T created a shift in how automotive components were sourced and produced. Before mass production, most parts were made in-house. After Ford’s success, specialized companies emerged to supply standardized parts to multiple car makers.

These suppliers became known as Original Equipment Manufacturers (OEMs), creating an ecosystem of companies focused on specific components like brakes, transmissions, and electrical systems. This specialization allowed for greater innovation in individual parts.

By the 1930s, major automakers worked with hundreds of OEMs. This relationship forced higher quality standards across the industry as parts needed to be interchangeable and reliable. The automotive industry began setting specifications that OEMs had to meet, raising the bar for all vehicles.

Scaling for Efficiency

Mass production fundamentally changed manufacturing economics through economies of scale. As production volumes increased, the cost per vehicle dropped dramatically. Ford’s Highland Park plant achieved a remarkable 90% productivity gain when implementing the assembly line.

This efficiency allowed automakers to offer more features while keeping prices accessible. Innovations like electric starters, hydraulic brakes, and enclosed cabins became standard rather than luxury features.

The availability of affordable gasoline further supported this scaling. As fuel distribution networks expanded, car ownership became practical for average families. This created a positive feedback loop – more cars led to more gas stations, which enabled more car sales.

By the 1950s, American automakers were producing millions of vehicles annually with increasingly higher standards. The demand for basic transportation that the Model T had met evolved into expectations for comfort, style, and performance.

The Electric Vehicle Revolution

Electric vehicles have transformed the automotive industry twice in the last century, first as early innovators and later as modern disruptors. This revolution has fundamentally changed how cars are produced and powered, with significant implications for consumers and the environment.

Advent of the Electric Car

Electric cars were actually among the first vehicles on American roads. In the early 1900s, electric vehicles competed with gas-powered cars, making up about one-third of all vehicles on the road. They offered several advantages over their gasoline counterparts, including:

- Quieter operation

- No difficult hand-cranking to start

- No gear shifting required

However, the mass-produced Model T made gasoline-powered cars widely available and affordable after 1908. The introduction of the electric starter in 1912 removed one of the major disadvantages of gasoline vehicles. This shift, combined with the discovery of cheap Texas crude oil, led to the decline of electric vehicles.

Electric vehicles remained mostly experimental until the 1960s, when environmental concerns began to renew interest in alternatives to internal combustion engines.

Technology and Tesla’s Influence

The modern electric vehicle revolution gained serious momentum with the founding of Tesla in 2003. Unlike previous attempts at electric vehicles that modified existing designs, Tesla built EVs from the ground up with several key innovations:

- Advanced lithium-ion batteries with improved range

- Software-focused approach to vehicle design

- Sleek, desirable aesthetic that changed consumer perceptions

Under Elon Musk’s leadership, Tesla revolutionized electric vehicles much as Ford’s Model T did for gasoline cars a century earlier. The 2012 Model S proved electric vehicles could be high-performance, desirable products rather than just eco-friendly compromises.

Tesla’s influence extends beyond its own vehicles. Their success forced traditional automakers to accelerate their electric vehicle programs, creating a competitive market with rapidly improving technology and decreasing prices.

Modern Mass Production Paradigms

While Ford revolutionized manufacturing a century ago, today’s automakers face new challenges in mass production. Tesla has pioneered innovative approaches to manufacturing electric vehicles that balance automation with human expertise.

Tesla’s Manufacturing Innovations

Tesla has reimagined automotive production by blending traditional assembly techniques with cutting-edge technology. Unlike Ford’s focus on singular models, Tesla designed its manufacturing process to be flexible enough to produce multiple vehicle types on the same line.

The company initially struggled with what Elon Musk called “production hell” during the Model 3 rollout. These challenges forced Tesla to rethink its approach to automation.

Tesla’s production now uses a balanced combination of robots and human workers. Robots handle dangerous or repetitive tasks, while humans manage complex assembly requiring judgment and finesse.

The company pioneered the use of mega casting machines that create large single parts, reducing the need for hundreds of smaller components. This approach decreases assembly time and improves structural integrity.

Achieving Economies of Scale with EVs

Electric vehicles initially cost more to produce than traditional vehicles, making economies of scale crucial for profitability. Tesla tackled this challenge by gradually increasing production volume to spread fixed costs across more units.

The Model 3 represents Tesla’s first truly mass-market vehicle, with production numbers reaching into the hundreds of thousands annually. This volume allows Tesla to negotiate better prices for components and materials.

Battery production represents the most expensive part of EV manufacturing. By bringing battery production in-house, Tesla cut costs significantly while maintaining quality control.

Vertical integration has become a key strategy for Tesla, producing many components that traditional automakers typically outsource. This approach reduces dependency on suppliers and lowers costs over time.

Role of the Gigafactory

Tesla’s Gigafactories represent a fundamental shift in automotive manufacturing philosophy. These massive facilities combine vehicle and battery production under one roof, dramatically reducing transportation costs and supply chain complexity.

The original Gigafactory in Nevada was built specifically to achieve unprecedented economies of scale in battery production. It remains one of the largest buildings by footprint in the world.

Tesla’s Gigafactories incorporate renewable energy sources like solar panels to power production. This approach reduces both energy costs and environmental impact.

Each new Gigafactory incorporates lessons learned from previous facilities. The Shanghai Gigafactory went from groundbreaking to vehicle production in less than a year, showcasing Tesla’s improving manufacturing efficiency.

The Gigafactory concept allows Tesla to adapt quickly to regional markets by producing vehicles closer to where they’ll be sold, reducing shipping costs and import duties.

The Consumer Shift to Electric Vehicles

The transition to electric vehicles has been driven by changing consumer preferences, technological advancements, and growing environmental awareness. This shift represents one of the most significant transformations in the automotive industry since the Model T.

Market Demand for EVs

Electric cars have experienced tremendous growth in consumer acceptance over the past decade. Once viewed as impractical alternatives to gasoline vehicles, EVs now command significant market attention.

Tesla led this revolution with the introduction of the Model S in 2012, which proved electric vehicles could be both luxurious and high-performing. This changed consumer perception dramatically.

The more affordable Model 3 launched in 2017 brought electric vehicles to a wider audience. It quickly became one of the best-selling electric cars worldwide and demonstrated the market’s readiness for mass EV adoption.

Consumer demand has been fueled by:

- Lower operating costs

- Reduced maintenance requirements

- Environmental benefits

- Technological features

- Improved driving experience

EVs in the Global Market

The global EV market has expanded rapidly across different regions. China leads in total EV sales, while Norway has achieved the highest per-capita adoption rate with electric vehicles representing over 80% of new car sales in some months.

Major automotive manufacturers have responded to this market shift by announcing ambitious electrification plans. Many have committed to phasing out internal combustion engines entirely within the next 10-15 years.

Government policies have significantly influenced EV adoption rates globally. Incentives, tax rebates, and infrastructure investments have accelerated the transition in countries like Norway, the Netherlands, and parts of China.

Battery technology improvements have been crucial for international growth. Falling costs and increased energy density have made EVs increasingly competitive with conventional vehicles on both price and range.

Sustainable Manufacturing and the Future

The automotive industry has evolved from Ford’s assembly line efficiency to Tesla’s eco-conscious production methods. This transformation represents a significant shift toward sustainable practices while maintaining mass production capabilities.

Environmental Considerations

Tesla has reimagined automotive manufacturing with sustainability at its core. Unlike traditional factories, Tesla’s Gigafactories aim to achieve net-zero energy consumption through renewable power sources. Solar arrays cover rooftops, and energy storage systems maximize efficiency.

Water recycling systems reduce waste in production processes. Tesla has also worked to shorten supply chains by localizing production and sourcing materials responsibly.

The company’s commitment extends to its products. Electric vehicles produce zero direct emissions, addressing a major environmental concern in the automotive sector. This approach stands in contrast to the Model T era when environmental impact was rarely considered in manufacturing decisions.

Material selection has evolved too. Tesla incorporates recycled materials in vehicle components and designs products for eventual recycling or reuse.

Advancements in Battery Technology

Battery technology represents the heart of electric vehicle innovation. Tesla has pushed boundaries by improving energy density in lithium-ion batteries, enabling longer ranges without increasing battery size or weight.

The company has reduced cobalt content in batteries, addressing both cost and ethical sourcing concerns. New battery chemistries like lithium iron phosphate offer improved safety profiles and longer lifespans.

Manufacturing improvements have dramatically reduced battery costs. From 2010 to 2022, lithium-ion battery prices fell by over 80%, making electric vehicles more affordable.

Tesla’s 4680 battery cells represent a significant breakthrough with:

- 5× energy capacity

- 6× power output

- 16% increased range

- Simplified manufacturing process

These innovations extend beyond vehicles to energy storage solutions for homes and power grids, creating a sustainable ecosystem.

The Road Ahead for Tesla and EVs

Electric vehicle adoption continues accelerating globally. Major markets including Europe and China have established future bans on internal combustion engines, creating clear timelines for the EV transition.

Tesla faces increasing competition as traditional automakers invest heavily in electric platforms. This competition drives further innovation and cost reductions across the industry.

Autonomous driving technology represents the next frontier. Tesla’s Full Self-Driving capability continues developing through over-the-air updates and machine learning.

Manufacturing will likely become even more automated. Modern automotive production now employs advanced robotics, AI-powered quality control, and increasingly sophisticated assembly techniques.

Battery recycling represents a critical focus area. As first-generation EVs reach end-of-life, efficient recycling processes will recover valuable materials and reduce environmental impact.

Comparative Analysis of Mass Production

The transformation of automotive manufacturing from the Model T era to Tesla’s modern approach highlights distinct philosophies and technological advancements that changed the industry twice in a century.

From Model T Principles to Tesla’s Innovations

Henry Ford’s Model T revolutionized manufacturing through standardization. Every Model T was identical—famously available in “any color so long as it’s black”—which enabled mass production techniques never seen before. Ford’s innovation wasn’t the car itself but the production method.

Tesla, meanwhile, embraced customization within standardization. While maintaining platform consistency, Tesla allows numerous configuration options for consumers. This approach combines mass production efficiency with personalization.

The Model T reduced costs so dramatically that Ford could double worker wages and cut prices simultaneously. Tesla’s challenge has been different—achieving scale while incorporating advanced technology.

Both companies faced similar production ramp challenges despite the 100-year gap between them, proving that scaling manufacturing remains difficult regardless of era.

The Evolution of the Production Line

Ford’s assembly line represented industrial revolution principles—specialization, standardization, and sequential assembly. Workers performed single tasks repeatedly as vehicles moved past them on conveyor systems.

Key Production Line Innovations:

- Model T: Fixed assembly line, human labor, mechanical tools

- Tesla: Flexible automation, robotics, AI-controlled processes

Tesla’s production incorporates extensive automation with robots handling complex tasks like welding and painting. However, Tesla learned that excessive automation can create bottlenecks—Elon Musk famously admitted “humans are underrated” after early Model 3 production struggles.

Both approaches transformed automotive manufacturing, but with different emphases. Ford focused on simplification and standardization, while Tesla balances automation with human oversight to manage complexity.

Frequently Asked Questions

The history of mass production connects two revolutionary vehicles – the Ford Model T and the Tesla Model 3. Each changed manufacturing in profound ways, transforming not just how cars were built but also their impact on society and economies.

How did the Model T revolutionize manufacturing processes in the early 20th century?

The Model T’s most significant innovation was the moving assembly line, introduced on December 1, 1913. Instead of workers moving to each vehicle, the car moved to stationary workers who performed specialized tasks.

This assembly line approach dramatically reduced production time from 12.5 hours to just 93 minutes per car. The efficiency gains allowed Ford to cut prices repeatedly while improving quality.

The Model T’s manufacturing process standardized tasks, minimized wasted movement, and created specialized roles that required less skilled labor. These principles formed the foundation of modern mass production techniques.

What role did interchangeable parts play in optimizing the production line for the Model T?

Interchangeable parts were essential to the Model T’s manufacturing success. Each component was designed to precise specifications, ensuring any part would fit any vehicle without custom fitting.

This standardization eliminated time-consuming hand-fitting and allowed for rapid assembly by less skilled workers. Parts could be mass-produced separately and then brought together efficiently on the assembly line.

The consistency of interchangeable parts also improved quality control and made repairs simpler. Owners could replace broken parts easily, extending vehicle lifespans and reducing maintenance costs.

To what extent did the Model T dominate the automobile market in its era?

The Model T achieved unprecedented market dominance, with more than 15 million units sold between 1908 and 1927. At its peak in the early 1920s, the Model T represented over half of all automobiles produced worldwide.

Ford’s market share reached as high as 60% in the United States during this period. The vehicle’s affordable price—dropping from $850 to under $300—made car ownership possible for middle-class Americans for the first time.

This market dominance transformed Ford from a small company to an industrial giant and forced competitors to adopt similar mass production techniques to remain competitive.

What were the overarching social implications of the widespread adoption of the Model T?

The Model T brought about profound social changes by making mobility accessible on an unprecedented scale. Rural isolation decreased as families could travel farther for work, education, and social activities.

The affordable automobile accelerated urbanization and suburbanization patterns, reshaping American cities and towns. New infrastructure like paved roads, gas stations, and motels emerged to support automobile travel.

The Model T created a new middle-class consumer culture centered around automobile ownership. It also established higher-wage manufacturing jobs, helping expand the American middle class and increasing overall prosperity.

How has Tesla’s approach to mass production differed from that of the Model T?

Tesla has reimagined mass production through automation and vertical integration. While Ford specialized workers on simple tasks, Tesla employs advanced robotics for precision alongside skilled technicians for complex assembly.

Tesla has developed new manufacturing processes that reportedly reduce EV production costs by 50% while using 40% less factory space. This approach contrasts with Ford’s expansive factory system.

Unlike Ford’s focus on a single, unchanging model, Tesla has built flexible production systems capable of handling multiple vehicle types and frequent design updates through software-centered manufacturing.

What technological advancements have enabled modern mass production methods compared to those used in the era of the Model T?

Computerized design and simulation tools have replaced the trial-and-error approach of the Model T era. Engineers can now test virtual prototypes before building physical components, reducing development time and costs.

Advanced materials science has introduced lightweight composites, high-strength alloys, and specialized polymers that weren’t available during the Model T’s production. These materials enable better performance, efficiency, and safety.

Robotics and automation handle repetitive tasks with greater precision than human workers, while artificial intelligence optimizes production scheduling and quality control. Connected factory systems track parts and vehicles throughout the manufacturing process with unprecedented accuracy.