Sticky throttle or hard-to-pull clutch levers can ruin a great ride. Motorcycle cables play a crucial role in controlling your bike, and when they’re not working smoothly, it can affect both performance and safety. The best way to maintain your motorcycle cables is to lubricate them regularly with a proper cable lubricant like chain and cable lube that contains molybdenum disulfide, not WD-40 which is primarily a solvent.

There are two main methods to lubricate your cables – either by removing them from the bike for thorough cleaning and lubrication, or by using a cable lubrication tool that allows you to inject lubricant while the cables remain installed. Both methods can be effective, but the key is doing it before your controls start feeling sticky or resistant.

Regular maintenance prevents more serious issues down the road. When cables move freely, you get better throttle response, smoother clutch engagement, and more reliable braking. This simple task only takes a few minutes but can make a significant difference in how your motorcycle handles and responds.

Key Takeaways

- Regular cable lubrication improves control response and prevents sticky throttles and hard-to-pull clutch levers.

- Use specialized cable lubricants containing molybdenum disulfide rather than general-purpose products like WD-40.

- Lubricate cables when they feel sticky or as part of regular maintenance to extend their lifespan and improve overall performance.

Why Lubricating Motorcycle Cables Is Essential

Regular maintenance of motorcycle cables prevents mechanical issues and improves your riding experience. Proper lubrication extends the life of these critical components while ensuring reliable performance.

Preventing Corrosion and Wear

Motorcycle cables operate in harsh environments where they’re exposed to moisture, dirt, and road grime. Without proper lubrication, these elements can cause corrosion inside the cable housing, leading to premature failure.

The inner wire and housing constantly rub against each other during normal operation. This friction accelerates wear when cables aren’t properly lubricated.

Routine lubrication creates a protective barrier between the inner wire and outer housing. This barrier prevents metal-on-metal contact that causes excessive wear.

Many riders don’t realize that cables need regular maintenance until they fail. A well-lubricated cable can last years longer than a neglected one.

Ensuring Smooth Control Response

Stiff or sticky controls make riding dangerous and unpleasant. Lubricating control cables ensures smoother operation of critical components like clutch, throttle, and sometimes brakes.

Poor cable response can cause:

- Inconsistent clutch engagement

- Sticky throttle operation

- Delayed braking (on bikes with cable brakes)

- Increased hand fatigue during long rides

A properly lubricated throttle cable provides consistent throttle response and prevents the cable from binding. This precision is especially important during low-speed maneuvers or emergency situations.

For clutch cables, smooth operation allows for better control when shifting gears. Riders can feel the difference immediately after lubricating a dry, sticky clutch cable.

Types of Motorcycle Cables That Need Lubrication

Not all motorcycle cables require the same maintenance approach. Some modern cables feature special coatings while others need regular attention to prevent sticking or failure.

Clutch Cables: Maintenance Importance

Clutch cables experience significant tension and frequent use, making them primary candidates for regular lubrication. These cables connect your left handlebar lever to the clutch mechanism and endure constant pulling forces.

Many Yamaha models use traditional clutch cables that benefit from routine maintenance. Without proper lubrication, clutch cables can become stiff, making it difficult to disengage the clutch smoothly.

Signs of a dry clutch cable include:

- Increased lever resistance

- Notchy or inconsistent feel

- Difficulty fully disengaging the clutch

- Strange noises when operating the lever

Even if manufacturers claim clutch cables don’t need maintenance, a small amount of cable-specific lubricant can extend their life dramatically. For older bikes without Teflon-lined cables, lubrication every 3-6 months is recommended.

Throttle Cables: Key Considerations

Throttle cables directly affect your control over the motorcycle’s power delivery. Most motorcycles use a dual-cable system (pull and return), both requiring proper maintenance.

KTM dirt bikes and other off-road motorcycles face particularly harsh conditions, making throttle cable maintenance critical. Dirt and grit can work their way into the cable housing, causing accelerated wear.

When lubricating throttle cables, it’s important to:

- Use a dedicated motorcycle cable lubricant

- Create a funnel to direct spray down the cable

- Work the throttle during application for even distribution

Newer throttle cables may have Teflon inner sheathes that require less maintenance, but checking manufacturer recommendations is always wise.

Shift Cables and Lesser-Known Controls

Beyond the primary controls, several other cables on motorcycles benefit from regular lubrication. Shift cables on certain models require attention, especially on dirt bikes that encounter mud and water.

Some Yamaha and KTM motorcycles also utilize cables for:

- Choke controls

- Decompression levers

- Hot start mechanisms

- Fuel petcock operation

These secondary cables are often overlooked but can cause significant inconvenience when they fail. Unlined cables should be lubricated using a dedicated aerosol spray and pressure lubricator.

For all these lesser-known controls, inspection during regular maintenance is key. Look for signs of fraying, binding, or excess friction. These cables typically don’t need lubrication as frequently as primary controls but shouldn’t be forgotten.

Selecting the Right Cable Lubricant

Choosing the proper lubricant for motorcycle cables significantly impacts their performance and lifespan. The right product reduces friction, prevents corrosion, and ensures smooth operation of throttle and clutch controls.

Dedicated Cable Lube Products

Specialized motorcycle cable lubricants are designed specifically for the unique demands of control cables. Products like chain and cable lube are formulated to penetrate the housing and coat inner cables effectively.

These dedicated products typically come with application tools that make the job cleaner and more efficient. Many riders prefer Lubit-8 Tufoil for its excellent penetration properties and lasting protection.

Cable lube tools vary in design and functionality. Some attach directly to the cable end while others work through pressure systems. A good cable lube tool makes application neater and ensures the lubricant reaches the entire length of the cable.

Using Spray Lubricants Safely

Spray lubricants offer convenience but require careful application. When using aerosol products, proper cable preparation is essential to ensure effective lubrication.

Steps for safe application:

- Disconnect the cable if possible

- Position a rag to catch excess spray

- Use the straw attachment for precision

- Apply in short bursts rather than continuous sprays

- Work the cable through its range of motion after application

Aerosol lubricants can be messy if not applied correctly. Many motorcycle mechanics recommend spraying into a cable tool rather than directly onto the cable end to minimize waste and overspray.

Always allow adequate drying time after application before operating the motorcycle to prevent slipping controls.

Pros and Cons of WD-40 and Alternatives

WD-40 is commonly found in garages but may not be ideal for cable lubrication. While it works as a temporary fix, it tends to dry out quickly and doesn’t provide lasting protection.

Better alternatives include:

- White lithium grease – Excellent staying power but can be messy

- Dry lubricants with Teflon – Clean application with good longevity

- Silicone-based lubricants – Water resistant with minimal dirt attraction

Motor oil is sometimes suggested but isn’t recommended as it can become sticky over time and attract contaminants. Proper motorcycle-specific lubricants typically contain additives that prevent gumming and resist water intrusion.

The best cable lubricants create a thin, long-lasting film that reduces friction without attracting dirt or gumming up the cable action.

Step-by-Step Guide to Lubricating Motorcycle Cables

Properly lubricating your motorcycle cables extends their life and improves performance. This maintenance task requires few tools but makes a big difference in how smoothly your controls operate.

Preparing the Motorcycle and Work Area

Start by parking your motorcycle on a stable surface. A center stand or motorcycle lift provides the best access to all cables. Gather all necessary tools and materials before beginning:

- Cable lubricant (specifically designed for motorcycle cables)

- Clean rags

- Basic hand tools for removing cable ends

- Cable luber tool (optional but recommended)

- Small container to catch excess lubricant

Ensure good lighting in your work area. Cover the surrounding parts with rags to protect them from dripping lubricant. This preparation prevents damage to painted or plastic surfaces.

Disconnecting and Inspecting Cables

First, identify which cables need maintenance. Common cables include throttle, clutch, and sometimes brake cables.

Locate the cable ends at the handlebar controls. For the clutch lever, loosen the adjuster completely before disconnecting. This creates slack in the cable, making removal easier.

Carefully disconnect the cable from the lever by removing any retaining clips or bolts. Inspect both cable ends for damage, wear, or fraying.

Check the cable sheath for cracks, kinks, or damage. If any significant damage is found, the cable should be replaced rather than simply lubricated. A damaged cable can fail unexpectedly.

Applying Lubricant Effectively

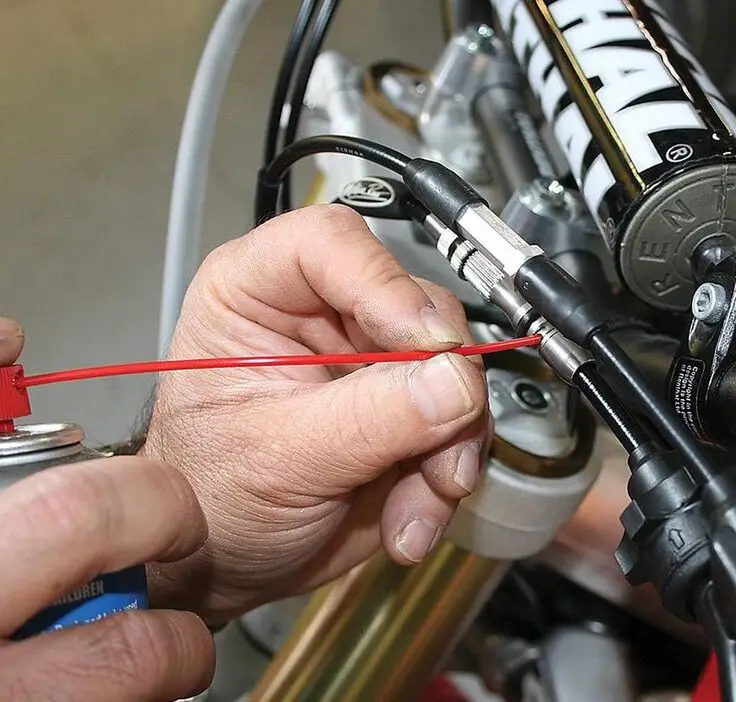

There are two main methods for lubricating motorcycle cables. The first uses a specialized cable luber tool that clamps around the cable and creates a seal for injecting lubricant.

If using a cable luber, attach it to the upper end of the cable where it connects to the handlebar. Insert the lubricant nozzle and slowly apply pressure until lubricant appears at the opposite end.

Without a special tool, you can hang the cable vertically and apply lubricant at the top opening. Gravity will help pull the lubricant through the cable sheath.

After lubrication, work the inner cable back and forth several times to distribute the lubricant evenly. Wipe away any excess from the cable ends before reconnecting to the controls.

Common Cable Lubrication Mistakes to Avoid

Properly maintaining your motorcycle cables requires avoiding certain pitfalls that can lead to poor performance or premature cable failure. Even with the best intentions, riders often make mistakes that can damage their cables or reduce their effectiveness.

Over-Lubricating or Under-Lubricating

Using too much lubricant is a common error that can actually harm your cables. Excess lube attracts dirt and debris, creating a gritty paste that increases friction and accelerates wear. This abrasive mixture can work its way into the housing and damage both the cable and its housing from the inside.

On the flip side, under-lubrication leaves cables vulnerable to friction and corrosion. Dry cables require more force to operate and can fray or snap under pressure.

What to do instead:

- Apply a thin, even coat of specialized cable lubricant

- Wipe away excess lube with a clean cloth

- Avoid using WD-40 or chain lube, which can gum up and damage cables

Neglecting Hard-to-Reach Areas

Many riders focus only on the visible parts of cables, missing crucial areas where lubrication is most needed. The bends and connection points often experience the most friction and are the first to fail when neglected.

Elbow joints and housing entry points require special attention as they’re high-stress areas. Without proper lubrication here, cables can bind or break when you need them most.

Pro Tip: Use a plastic bag method to reach difficult areas. Cut the corner from a zip-lock bag, place it inside-out over the cable end, and secure with a rubber band. This creates a reservoir that helps the lubricant penetrate the entire cable length.

For best results, apply lubricant with the cable disconnected at one end. This allows the product to flow through the entire housing and reach all critical areas.

Recommended Lubrication Schedules for Different Motorcycle Types

Different motorcycle types require varying cable lubrication schedules based on their usage conditions and exposure to elements. The frequency of maintenance directly impacts control responsiveness and overall riding safety.

Routine Maintenance for Street Bikes

Street bikes operated in typical conditions should have their cables lubricated every 4,000-6,000 miles or at least once a year. Daily commuters in urban environments may need more frequent attention due to exposure to road grime and pollutants.

Street Bike Lubrication Schedule:

- Normal conditions: Every 4,000-6,000 miles

- Rainy/coastal areas: Every 3,000 miles

- Winter riding (with road salt): Monthly

Bikes with unlined cables require more frequent lubrication than those with modern dedicated lubricant systems. Older motorcycles may need attention every 2,000 miles to prevent cable binding.

For optimal performance, apply a dedicated chain and cable lubricant rather than general-purpose products. This ensures proper viscosity and lasting protection.

Dirt Bikes and Off-Road Motorcycles

Dirt bikes and off-road motorcycles face harsh conditions that demand more frequent cable maintenance. Brands like KTM and Yamaha recommend cable lubrication after every 5-10 hours of riding in dusty or muddy conditions.

Off-Road Lubrication Schedule:

| Riding Conditions | Recommended Frequency |

|---|---|

| Dusty terrain | Every 5-10 hours |

| Muddy conditions | After each ride |

| Water crossings | Immediately after ride |

KTM dirt bikes with their exposed cable systems are particularly susceptible to dirt infiltration. Their maintenance manuals often specify using dry lubricants or graphite to prevent attracting additional dirt.

Yamaha off-road models benefit from removing the cables completely during major service intervals (approximately every 20 hours of riding) for thorough cleaning and lubrication.

Signs Your Motorcycle Cables Need Lubrication

Motorcycle cables often signal when they require attention through changes in performance and appearance. Regular inspection can help identify these issues before they lead to cable failure or unsafe riding conditions.

Stiff or Sticky Controls

When motorcycle cables need lubrication, the most noticeable symptom is increased resistance when operating the controls. The clutch lever may become difficult to pull, requiring more hand strength than usual. This stiffness often develops gradually, making it easy to miss until it becomes severe.

Throttle response might feel sluggish or sticky, with the throttle not returning to idle position smoothly when released. This can create dangerous riding conditions, especially in emergency situations where quick throttle control is essential.

Cold weather typically worsens these symptoms as old lubricant thickens. If your bike’s controls feel rough or hard to pull, it’s likely time for cable maintenance.

Some riders notice a gritty feeling or unusual noise when operating the controls. This indicates dirt contamination within the cable housing, which can accelerate wear.

Visible Wear and Fraying

External inspection can reveal several visual indicators that cables need lubrication. Check cable housings for cracks, kinks, or rust spots that might suggest internal problems. These damaged areas often correlate with internal friction points.

Exposed cable ends near connection points may show signs of fraying or individual wire breakage. Even minor fraying suggests advanced wear that lubricating might not fully resolve. In these cases, complete cable replacement might be necessary.

Look for dark residue or grime at cable entry points, which indicates old lubricant mixing with dirt. This contaminated mixture accelerates cable wear rather than reducing it.

Check for any unusual bends or tight routing in the cable path. Poor routing creates excessive friction points that require more frequent lubrication maintenance.

How to Prolong the Life of Your Motorcycle Cables

Proper maintenance extends the lifespan of motorcycle cables significantly, preventing costly replacements and avoiding dangerous failures during rides. Regular care keeps controls smooth and responsive.

Protecting Cables from Contaminants

Dirt, water, and road grime are major enemies of motorcycle cables. Lubricate your cables regularly with proper cable lubricants, not WD-40, which can damage rubber components.

A specialized cable luber tool makes the job easier and more effective. These devices create a seal around the cable, allowing lubricant to flow through completely.

Always clean cables before lubricating them. This removes existing grime that can mix with fresh lubricant and create a grinding paste inside the cable housing.

For riders in wet or dusty environments, consider installing rubber boots or seals at cable entry points. These simple shields prevent water and debris from entering the cable housing.

Safe Storage and Handling Tips

Never make sharp bends in control cables as this creates weak points and accelerates wear. When routing cables during maintenance, ensure smooth curves with no kinks or pinch points.

Inspect cable housing regularly for cracks or splits. Damaged housing allows moisture and contaminants to reach the inner cable, causing corrosion and sticky operation.

When storing a motorcycle for extended periods, fully lubricate all cables before storage. This prevents internal corrosion while the bike sits unused.

For winter storage, consider slightly loosening throttle and clutch cables to reduce tension. This helps prevent the inner cable from stretching over time.

Replace any cable that shows signs of fraying or binding. A sticky throttle or clutch can be dangerous in emergency situations.

Frequently Asked Questions

Proper motorcycle cable maintenance involves using the right lubricants and following a regular schedule to keep cables operating smoothly. Understanding the best products and techniques can extend the life of your control cables and improve your riding experience.

What type of lubricant is recommended for motorcycle cables?

The best lubricants for motorcycle cables are lightweight oils or specifically formulated cable lubricants. These products provide excellent penetration while reducing friction between the inner cable and housing.

Cable-specific lubricants often contain additives that prevent corrosion and help displace moisture. Products designed for motorcycle cables will typically state this purpose clearly on the packaging.

Many riders prefer silicone-based lubricants as they don’t attract dust and dirt like some petroleum-based products might.

How often should I lubricate my motorcycle’s throttle and clutch cables?

Motorcycle cables should be lubricated at least once a year as part of regular maintenance. This annual schedule represents the minimum frequency for riders who don’t put many miles on their bikes.

Riders who use their motorcycles frequently or in harsh conditions should lubricate cables more often. Signs that cables need lubrication include stiff operation, sticking, or unusual resistance.

Weather exposure can accelerate the need for lubrication, particularly in rainy or humid climates where moisture can affect cable performance.

Is it necessary to use a cable lube tool for motorcycle cable maintenance?

While not absolutely necessary, cable lubrication tools make the job significantly easier and more effective. These tools help deliver lubricant directly inside the cable housing where it’s needed most.

A cable lube tool typically attaches to the end of the cable and creates a seal that helps force the lubricant through the entire length of the cable. This ensures complete coverage that’s difficult to achieve otherwise.

For riders without a specialized tool, alternative methods exist but may not provide the same level of thorough lubrication.

Are there alternatives to commercial cable lubricants for motorcycles?

In a pinch, lightweight machine oil or even WD-40 can be used to lubricate motorcycle cables, though these aren’t ideal long-term solutions. These alternatives may provide temporary relief but lack the staying power of dedicated products.

Some riders report success using various oils from their garage, but commercial motorcycle cable lubricants are specifically formulated for this application.

Graphite lubricants can work in dry environments but aren’t recommended in wet or humid conditions where they can become gummy.

What are the steps to properly lubricate a motorcycle cable?

Start by disconnecting one end of the cable if possible to provide better access. This usually means removing the cable from the lever or throttle assembly.

Apply lubricant using a cable lube tool attached to the exposed end, or use the plastic bag method by securing a small bag containing lubricant around the cable end.

Work the control (throttle or clutch) several times after application to distribute the lubricant throughout the entire cable length.

What are the consequences of not lubricating motorcycle cables regularly?

Neglected cables can develop internal friction that leads to stiff operation and eventually cable failure. This stiffness creates a poor riding experience and can be dangerous in emergency situations.

Unlubricated cables are susceptible to rust and corrosion, particularly in areas with high humidity or where the motorcycle is exposed to rain or snow.

The cost of replacing damaged cables is significantly higher than the minimal expense of regular lubrication, making preventive maintenance both safer and more economical.