Modern race cars have transformed the way they handle braking through advanced energy recovery systems that capture power normally lost as heat. Regenerative braking technology allows racing vehicles to convert kinetic energy from braking back into electrical energy, which can then boost performance and extend range during competition. This system has become essential in motorsport categories from Formula 1 to Formula E.

Formula 1 cars have used regenerative braking technology since 2009, marking a shift toward hybrid powertrains in high-level racing. The technology works through Motor Generator Units that act as both energy harvesters during braking and power boosters during acceleration. Racing teams use sophisticated control systems to manage when and how much energy gets recovered or deployed.

The impact extends beyond simple energy savings. These systems affect vehicle dynamics, braking balance, and race strategy in ways that reshape how drivers and engineers approach competition. Understanding how regenerative braking works in racing environments reveals the cutting-edge technology that often makes its way into everyday vehicles.

Key Takeaways

- Regenerative braking converts wasted braking energy into stored electrical power that racing cars can use for performance boosts

- The technology requires complex control systems to balance traditional hydraulic brakes with energy recovery systems

- Racing applications of regenerative braking drive innovation that eventually appears in consumer hybrid and electric vehicles

Fundamentals of Regenerative Braking

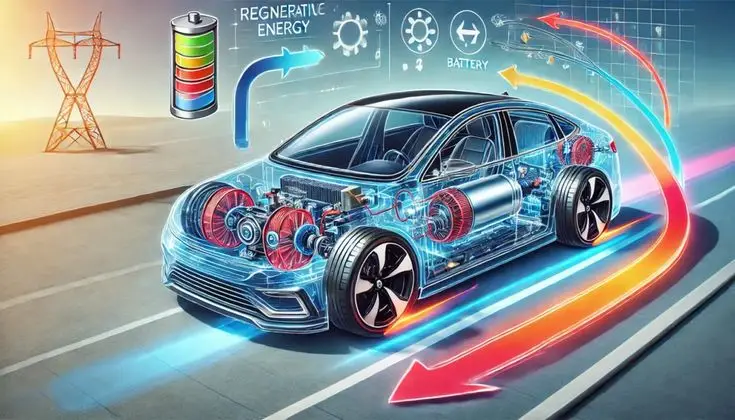

Regenerative braking systems capture kinetic energy during deceleration and convert it into electrical energy for storage. This process fundamentally differs from traditional braking by recovering energy instead of wasting it as heat.

Principles of Energy Recovery

Regenerative braking systems capture energy that would normally be lost during the braking process. The system works by reversing the role of the electric motor during deceleration.

When a race car slows down, the wheels continue spinning due to momentum. The regenerative system connects these spinning wheels to a Motor Generator Unit (MGU). This connection allows the rotational motion to drive the generator.

The generator creates electrical current as it spins. This current flows into the car’s battery system for temporary storage. The stored energy can then power the vehicle during acceleration or provide additional boost when needed.

Key Components:

- Motor Generator Unit (MGU)

- Energy storage battery

- Control electronics

- Power management system

The efficiency of energy recovery depends on several factors. Braking force, vehicle speed, and battery charge level all affect how much energy the system captures.

Kinetic Energy Conversion

Kinetic energy conversion transforms the car’s motion into usable electrical power through electromagnetic principles. The process begins when the driver applies the brakes and the MGU switches from motor mode to generator mode.

The spinning wheels transfer their rotational energy through the drivetrain to the MGU. Inside the unit, magnets rotate past copper coils, creating electrical current through electromagnetic induction.

This electrical energy flows through power electronics that regulate voltage and current. The system ensures the battery receives the correct amount of power without overcharging or damage.

Conversion Process:

- Kinetic energy from wheel rotation

- Mechanical energy transfer to MGU

- Electromagnetic induction creates electricity

- Power conditioning and battery storage

The amount of energy recovered varies with braking intensity. Light braking recovers less energy but allows for smoother deceleration. Heavy braking captures more energy but may require additional friction braking.

Comparison With Traditional Braking

Traditional braking systems convert kinetic energy into heat through friction between brake pads and rotors. This heat dissipates into the atmosphere, representing completely lost energy.

Regenerative systems recover a portion of kinetic energy instead of converting it all to waste heat. However, they cannot handle all braking duties alone, especially during emergency stops.

Traditional Braking:

- Converts 100% of energy to heat

- Immediate maximum braking force

- No energy recovery

- Brake wear from friction

Regenerative Braking:

- Recovers 15-25% of braking energy

- Limited by motor capacity

- Reduces brake wear

- Requires backup friction system

Most race cars use a combination of both systems. The regenerative system handles moderate braking while friction brakes provide additional stopping power when needed. This hybrid approach maximizes energy recovery while maintaining safety and performance.

The integration requires sophisticated control systems. These systems balance regenerative and friction braking to provide consistent pedal feel and optimal energy capture throughout different racing conditions.

How Regenerative Braking Systems Work in Race Cars

Regenerative braking systems in race cars convert kinetic energy into electrical energy during braking, then store this energy for later use. These systems work alongside traditional friction braking to provide both energy recovery and consistent stopping power.

Key Components and Operation

The Motor Generator Unit (MGU) serves as the heart of regenerative braking systems in race cars. This component acts as both a motor and generator depending on the racing situation.

During braking, the MGU operates as a generator. It converts the car’s kinetic energy into electrical energy through electromagnetic induction. The system captures energy that would otherwise be lost as heat through traditional brake pads.

The electrical energy flows to a battery pack called an Energy Store (ES). Formula 1 cars limit the MGU-K to 50,000rpm with maximum power output of 120kW.

When the driver needs extra power, the stored energy reverses direction. The MGU switches to motor mode and sends additional torque to the wheels. This process happens within milliseconds during racing.

Role of Electric Motors

Electric motors in regenerative braking systems provide dual functionality for race cars. They generate electricity during deceleration and deliver power during acceleration phases.

The motor creates resistance when harvesting energy. This resistance acts like engine braking and helps slow the car naturally. Drivers can feel this effect through the brake pedal and steering wheel.

Formula E cars use electric motors on both front and rear axles for maximum energy recovery. The front motor handles regeneration while the rear motor provides both regeneration and propulsion.

Motor efficiency directly affects race performance. Better motors capture more energy per braking event. This means longer battery life and more power available for overtaking or defending position.

Integration With Friction Braking

Race cars combine regenerative braking with traditional friction braking for safety and performance. Regenerative braking cannot bring vehicles to complete stops at low speeds with current technology.

Brake-by-wire systems manage this integration electronically. These systems automatically adjust the balance between regenerative and friction braking. The driver experiences consistent pedal feel regardless of which system provides the stopping force.

Three braking forces work together:

- Engine braking from the combustion engine

- Regenerative braking from the electric motor

- Hydraulic braking from brake pads and rotors

The electronic control system prevents overcharging the battery. When the battery reaches full capacity, the system shifts more braking duty to the friction brakes. This maintains consistent braking performance throughout the race.

Energy Storage and Management

Race cars use sophisticated energy storage systems that combine batteries with supercapacitors to handle rapid power demands during acceleration and braking. Energy management systems coordinate these components to maximize performance while protecting battery life through precise charge and discharge control.

Battery Technology in Race Cars

Modern race cars rely on lithium-ion battery technology designed for high power output rather than maximum capacity. These batteries must deliver instant power for acceleration while accepting rapid charging during regenerative braking events.

Racing batteries typically use lithium iron phosphate or lithium titanate chemistry. These chemistries handle high charge and discharge rates better than standard automotive batteries. They also maintain performance across temperature extremes found on race tracks.

Battery technology advances have made hybrid racing power units more effective. The energy storage system must survive vibration, heat, and G-forces that would destroy regular car batteries.

Battery life becomes critical during endurance races. Teams balance aggressive energy recovery with protecting the battery from damage caused by excessive charging rates or deep discharge cycles.

Supercapacitors and Hybrid Storage

Supercapacitors excel at storing and releasing energy quickly, making them perfect partners for racing batteries. They handle the rapid power spikes during braking and acceleration that can stress battery systems.

Hybrid race cars utilize capacitors for regenerative braking by converting kinetic energy into electrical energy stored in the capacitors. When drivers apply brakes, the system captures energy that would otherwise be lost as heat.

The combination creates a hybrid energy storage system. Supercapacitors manage short-term power demands while batteries provide sustained energy output. This approach extends battery life and improves overall system efficiency.

Teams must balance the weight and complexity of dual storage systems against performance gains. Supercapacitors add weight but reduce stress on the primary battery pack.

Energy Management Strategies

Sophisticated control systems carefully manage the amount of energy stored in capacitors and batteries. These systems monitor battery state of charge, temperature, and power demands in real time.

Energy management algorithms decide when to use stored energy for maximum lap time advantage. They consider factors like remaining race distance, battery temperature, and upcoming track sections that favor electric assist.

The system prioritizes battery protection during extreme conditions. It may limit regenerative braking power if batteries are too hot or fully charged. This prevents damage that could end a race prematurely.

Racing teams develop custom energy management strategies for different tracks and race conditions. These strategies determine when to harvest energy aggressively and when to deploy stored power for overtaking or defending position.

Impact on Braking Performance and Vehicle Dynamics

Regenerative braking systems transform how race cars handle deceleration by converting kinetic energy into electrical power while maintaining precise control. This technology delivers measurable improvements in braking efficiency and creates new opportunities for performance optimization during races.

Braking Performance Enhancement

Modern race cars with regenerative braking achieve superior stopping power through coordinated motor and friction brake control. The electric motor provides instant torque response that improves average deceleration by 10.9% and shortens braking distance by 5% compared to traditional friction-only systems.

Race engineers can adjust regenerative braking intensity based on track conditions and racing strategy. The system works most effectively at high speeds when kinetic energy levels are greatest.

Key Performance Benefits:

- Faster response times than hydraulic systems

- Consistent braking force regardless of brake pad temperature

- Reduced brake fade during extended racing sessions

- Better weight distribution control through rear-axle regeneration

The first regenerative braking systems in motorsport appeared in the 1998 Panoz Q9 GTR-1 Hybrid. This endurance racing car demonstrated the technology’s potential by winning its class at the inaugural Petit Le Mans race.

Efficiency Ratings and Energy Conservation

Energy recovery rates in racing applications typically range from 25% to 40% of total braking energy. The exact percentage depends on track layout, driving style, and system configuration.

Research shows that approximately 30-50% of total energy consumption in urban traffic goes to friction braking. Race tracks with frequent braking zones offer similar energy recovery opportunities.

Efficiency Factors:

- Motor generator efficiency (typically 85-95%)

- Battery charging rates and capacity

- Transmission system losses

- Low-speed motor cutoff characteristics

Race teams monitor energy flow data in real-time to maximize recovery during practice and qualifying sessions. Higher efficiency ratings translate directly into extended electric power availability for acceleration phases.

Effects on Vehicle Performance

Regenerative braking alters vehicle weight distribution and handling characteristics during corner entry. The system adds electrical components that affect overall vehicle mass and center of gravity positioning.

Performance Impacts:

- Weight: Battery packs and motor-generators add 50-150 kg

- Balance: Rear-mounted systems shift weight distribution rearward

- Handling: Changed brake bias affects turn-in characteristics

- Reliability: Additional complexity requires careful system integration

Race car designers must account for these changes when developing suspension setups and aerodynamic packages. The technology plays a principal role in safety, comfort and economic operation while requiring new approaches to vehicle dynamics optimization.

Teams often adjust brake balance controllers to compensate for regenerative system variations across different speed ranges and battery charge states.

Applications and Evolution in Motorsport

Racing series have transformed regenerative braking from experimental technology into essential competition tools. Formula E leads with fully electric powertrains while hybrid systems dominate endurance racing and Formula 1.

Implementation in Formula E and Modern Series

Formula E represents the pinnacle of regenerative braking technology in motorsport. The current Gen3 cars use regenerative braking on both front and rear axles, doubling the energy recovery capacity compared to original Gen1 vehicles.

These electric vehicles feature Front Powertrain Kits that enable energy harvesting during braking. The system captures kinetic energy and converts it back into electrical power for the battery pack.

Formula E cars use fully decoupled brake systems. No direct hydraulic connection exists between the brake pedal and calipers. Electronic sensors control the braking force distribution between regenerative and hydraulic systems.

Key Formula E Features:

- Regenerative braking on front and rear wheels

- Double the energy recovery of early systems

- Fully electronic brake control

- Emergency hydraulic backup systems

Other electric racing series like Extreme E also rely heavily on regenerative braking for competitive advantage.

Advancements in Hybrid and Electric Race Cars

Formula 1 introduced KERS (Kinetic Energy Recovery System) in 2009, providing 80 horsepower for 6.67 seconds per lap. Modern F1 cars use advanced MGU-K systems that integrate with turbocharger energy recovery.

The 1998 Panoz Q9 GTR-1 Hybrid pioneered regenerative braking in endurance racing. Despite adding 200kg in battery weight, it won its class at Petit Le Mans.

Battery technology improvements have made modern systems 75% lighter than early versions. The 2012 Toyota TS030 became the first hybrid car to achieve major success, winning five World Endurance Championship races.

Evolution Timeline:

- 1998: Panoz Q9 debuts regenerative braking

- 2009: F1 introduces KERS

- 2012: Toyota TS030 wins with hybrid power

- 2014: F1 hybrid era begins

- 2022: Formula E Gen3 cars launch

Influence on the Automotive Industry

Motorsport racing has played a significant role in developing braking systems for production vehicles. Racing innovations transfer directly to consumer electric vehicles and hybrid vehicles.

The Toyota Prius commercialized regenerative braking technology that originated in motorsport development. Most hybrid and electric vehicles now use systems derived from racing applications.

Automotive technology advances through competition pressure. Racing teams push regenerative braking efficiency to maximize performance and energy recovery under extreme conditions.

Industry Applications:

- Production hybrid vehicles

- Electric vehicles (EVs)

- Brake-by-wire systems

- Energy management software

The automotive industry benefits from racing’s rapid development cycles and performance demands. Technologies proven on track reach consumer vehicles within years rather than decades.

Sustainability and Future Directions

Racing organizations are implementing comprehensive sustainability programs while addressing traditional concerns about vehicle range and fuel efficiency. These initiatives focus on measurable carbon reduction targets and practical solutions for energy management in competitive motorsports.

Sustainable Mobility Initiatives

Modern racing series have adopted eco vehicles and sustainable practices to reduce their environmental impact significantly. Formula E leads this transformation by using fully electric vehicles and renewable energy sources for charging infrastructure.

Major racing organizations now require teams to meet specific sustainability benchmarks. These include using recycled materials in car construction and implementing zero-waste policies at racing facilities.

Racing series also partner with manufacturers to develop new sustainable transportation technologies. These collaborations test innovations under extreme conditions before they reach consumer vehicles.

Key sustainable mobility measures include:

- Electric powertrains in multiple racing categories

- Renewable energy charging stations at tracks

- Recycled carbon fiber components

- Biofuel alternatives for support vehicles

- Digital tire pressure monitoring to reduce waste

Reducing Carbon Footprint in Racing

Racing teams track and report their carbon emissions across all operations. Transport logistics account for the largest portion of motorsport emissions, prompting changes in shipping methods and race calendar organization.

Teams now use hybrid freight systems and consolidated shipping to minimize transportation impact. Some series have reduced the number of overseas races to cut aviation fuel consumption.

Track facilities invest in solar panels and energy-efficient lighting systems. Many venues achieve carbon-neutral status through renewable energy purchases and offsetting programs.

Carbon reduction strategies:

| Strategy | Impact |

|---|---|

| Regional race scheduling | 30% less transport emissions |

| Hybrid support vehicles | 25% fuel savings |

| LED track lighting | 60% energy reduction |

| Solar-powered facilities | 40% grid independence |

Addressing Range Anxiety and Fuel Consumption

Electric race cars now achieve competitive lap times while maintaining sufficient energy for full race distances. Advanced regenerative braking systems allow drivers to recover up to 20% of energy during braking phases.

Battery technology improvements have extended race car range significantly. Modern electric racing vehicles complete 200-mile races without mid-race charging stops.

Teams use sophisticated energy management software to optimize power delivery throughout races. These systems balance maximum performance with energy conservation requirements.

Racing series implement standardized charging protocols to ensure consistent performance across all teams. Fast-charging capabilities allow for strategic energy top-ups during pit stops when regulations permit.

Energy efficiency improvements:

- Battery capacity: Increased 40% in five years

- Charging speed: 150kW fast-charging standard

- Energy recovery: 20% through regenerative braking

- Weight reduction: 15% lighter battery packs

Frequently Asked Questions

Regenerative braking systems in race cars convert kinetic energy into electrical power during deceleration. These advanced systems offer both performance benefits and technical challenges for drivers and teams in professional motorsport.

How does regenerative braking technology function in electric race cars?

Electric race cars use a Motor Generator Unit (MGU) that acts as both a motor and generator. When the driver applies the brakes, the MGU switches from powering the wheels to capturing energy from them.

The system converts the car’s kinetic energy into electrical energy during braking. This electrical power gets stored in the battery pack for later use. Formula E cars use regenerative braking on both front and rear axles through specialized systems.

The MGU connects to the drivetrain and operates at speeds up to 50,000 rpm in Formula 1 cars. Electronic control systems manage the balance between regenerative braking and traditional hydraulic brakes automatically.

What are the advantages and disadvantages of using regenerative braking in high-performance vehicles?

Regenerative braking allows race cars to recover energy that would normally be lost as heat. This recovered energy can provide extra power for acceleration and overtaking maneuvers.

The main advantage is improved energy efficiency and extended range in electric racing series. Teams can also use fewer pit stops due to better fuel economy in hybrid systems.

However, early systems added significant weight to race cars. The 1998 Panoz Q9 GTR-1 Hybrid’s battery pack added around 200kg, which hurt performance.

Modern systems create complex braking dynamics that drivers must adapt to. The varying brake feel between regenerative and hydraulic braking can affect driver confidence and control.

Can the regenerative braking system in a race car be manually controlled or adjusted by the driver?

Race car drivers can adjust regenerative braking settings through controls on their steering wheels. They can change the strength of energy recovery and brake balance between front and rear wheels.

F1 drivers use steering wheel controls to manage braking effort and energy harvesting strategies. However, automatic control systems handle most adjustments to maintain consistent performance.

Drivers can choose when to deploy stored energy for maximum power output. In early KERS systems, drivers could use the extra power in one burst or spread it across multiple moments per lap.

The brake-by-wire systems provide electronic control while giving drivers feedback through pedal simulation. This helps maintain the natural braking feel that drivers need for precise control.

What impact does regenerative braking have on the overall efficiency and performance of racing vehicles?

Regenerative braking significantly improves energy efficiency in electric and hybrid race cars. It allows vehicles to recover up to 30% of the energy normally lost during braking.

In Formula 1, the MGU-K system can provide up to 120kW of additional power. This extra power helps with acceleration out of corners and enables strategic overtaking moves.

Current Formula E Gen3 cars have double the regeneration capacity of the original 2014 cars. This improvement directly extends race distance and reduces energy consumption.

The technology also enables different racing strategies. Teams can focus on energy management rather than just speed, adding a new tactical element to motorsport.

How is the energy captured through regenerative braking stored and reused in race cars?

Energy captured during braking gets stored in high-voltage battery packs called Energy Stores. These batteries use advanced lithium-ion technology designed for rapid charging and discharging cycles.

The stored electrical energy flows back to the MGU when drivers need extra power. The system can deliver this energy almost instantly for acceleration or overtaking.

Battery management systems control charging to prevent overcharging and maintain optimal performance. The stored energy must be used strategically since storage capacity is limited by racing regulations.

In Formula 1, drivers can deploy stored energy for 33.3 seconds per lap at maximum power. The timing and duration of energy deployment becomes a crucial part of race strategy.

To what extent has regenerative braking technology been adopted in professional racing series like Formula 1?

Formula 1 introduced regenerative braking with KERS in 2009 and expanded it with hybrid power units in 2014. All current F1 cars use MGU-K systems as mandatory technology.

The World Endurance Championship requires hybrid powertrains with regenerative braking in its top classes. Formula E has used the technology since its debut in 2014 as the primary braking method.

Other series like Extreme E and various GT racing categories have adopted regenerative braking systems. The technology is becoming standard in high-level motorsport competitions worldwide.

From 2026, F1 regulations will place even more emphasis on regenerative braking by removing the MGU-H system. This change will make the MGU-K system more critical for performance and efficiency.