Detroit’s journey to becoming the “Motor City” began in the late 1800s when tinkerers and visionary manufacturers laid the groundwork for what would become the heart of America’s automotive industry. When pioneers like Ransom E. Olds opened the city’s first auto manufacturing plant and Henry Ford founded the Ford Motor Company in 1903, Detroit was only the 13th largest city in the nation. By the time Ford’s Model T entered production in 1908, the tide had already turned decisively in Detroit’s favor, setting the stage for Detroit to transform into the global center of automobile manufacturing.

The rapid growth of the “Big Three” auto companies—General Motors, Ford, and Chrysler—all headquartered in metropolitan Detroit, created an economic powerhouse that shaped not just the city but the entire nation. The auto industry consumed enormous quantities of raw materials and created jobs for thousands of workers, triggering a population boom. This industrial might helped Detroit grow from a modest manufacturing town into a symbol of American innovation and productivity.

Key Takeaways

- Detroit evolved from the nation’s 13th largest city to the automotive capital through early pioneers like R.E. Olds and Henry Ford.

- The Big Three auto companies transformed Detroit into an economic powerhouse that shaped America’s industrial landscape.

- The Ford Model T marked a turning point that cemented Detroit’s status as the world’s automotive manufacturing center.

Rise of the Motor City

Detroit transformed from a modest industrial city into the global center of automobile manufacturing in the early 20th century. This remarkable change came through pioneering manufacturing techniques, visionary leadership, and industrial innovation that would forever change how products were made worldwide.

Henry Ford and the Model T

Henry Ford founded the Ford Motor Company in Detroit in 1903, marking the beginning of the city’s rise as an automotive powerhouse. His vision went beyond simply building cars—he wanted to make automobiles affordable for average Americans.

The introduction of the Model T in 1908 revolutionized transportation in America. Priced at just $825 (about $24,000 today), it was significantly cheaper than other vehicles of its time. Ford’s commitment to efficiency and affordability helped turn the tide in Detroit’s favor as the center of auto manufacturing.

By 1914, Ford had produced over 500,000 Model Ts. As production increased, prices dropped even further, making car ownership possible for millions of Americans and cementing Detroit’s reputation as the heart of automotive innovation.

Olds Motor Works and the Moving Assembly Line

Before Ford perfected mass production, Ransom E. Olds made crucial contributions to automotive manufacturing in Detroit. In 1899, Olds established one of the first auto manufacturing plants in the city, pioneering early production techniques.

Olds created the first automotive assembly line, though it was stationary rather than moving. Workers would move between stations to assemble components on vehicle frames. This method significantly increased production efficiency compared to handcrafting entire vehicles.

Ford later improved upon this concept with the moving assembly line in 1913, where the car moved through the factory on a conveyor while workers performed specific tasks. This innovation reduced the time to build a Model T from 12 hours to just 93 minutes.

The assembly line approach transformed manufacturing worldwide and helped establish Detroit as a center for industrial innovation and efficiency.

The Big Three: Ford, General Motors, and Chrysler

Detroit’s automotive dominance grew with the emergence of the “Big Three” manufacturers. General Motors, formed in 1908 by William Durant, consolidated several smaller car companies and introduced the concept of annual model changes to encourage repeat purchases.

Chrysler Corporation joined the scene later, founded in 1925 by Walter Chrysler. Together with Ford, these companies employed hundreds of thousands of workers and produced millions of vehicles annually by the 1920s.

Competition between the Big Three drove innovation in design, features, and manufacturing processes. They established massive industrial complexes throughout Detroit and its suburbs, creating an economic ecosystem that supported countless supplier businesses.

This industrial concentration transformed Detroit from a diverse manufacturing city into a specialized automotive powerhouse, with the automobile industry becoming the primary economic driver for the entire region.

Detroit as the Hub of American Innovation

Beyond manufacturing cars, Detroit became a center for technological advancement. Research and development laboratories established by automotive companies generated thousands of patents and innovations that extended beyond vehicles.

The city attracted engineering talent from across America and around the world. Technical schools and apprenticeship programs developed specialized workers skilled in the latest manufacturing techniques.

Detroit’s innovation ecosystem tackled challenges in metallurgy, chemistry, and precision machining. Advancements made for automobile production found applications in other industries, including aviation, home appliances, and military equipment.

By the 1930s, Detroit had established itself as America’s premier industrial research center. The concentration of technical expertise, manufacturing capability, and business acumen created a unique environment where ideas could quickly move from concept to mass production, solidifying the city’s reputation as the global symbol of automotive manufacturing.

Golden Age and Diversification

Detroit’s automotive industry experienced massive growth and transformation through several key periods of American history. The city’s car manufacturers adapted to changing economic conditions while solidifying Detroit’s reputation as the Motor City.

Expansion and Contribution to World War I

When World War I began in 1914, Detroit’s car industry shifted to support the war effort. The Automobile Industry converted production lines to manufacture military vehicles, aircraft engines, and munitions.

Ford, Cadillac, and Packard Motor Car Co. played crucial roles in this industrial mobilization. Cadillac contributed by producing engines for the Liberty aircraft program, while Ford built submarine chasers and ambulances.

This period marked significant advancement in assembly line techniques. Mass production methods pioneered in auto manufacturing proved invaluable for wartime production.

By the war’s end in 1918, Detroit manufacturers had demonstrated remarkable adaptability. Their contributions helped establish American industrial dominance and positioned Detroit companies for tremendous growth in the following decade.

The Roaring Twenties and Diverse Auto Manufacturers

The 1920s represented a true golden age for Detroit’s automotive sector. Car ownership became more accessible to average Americans, and manufacturing boomed across the city.

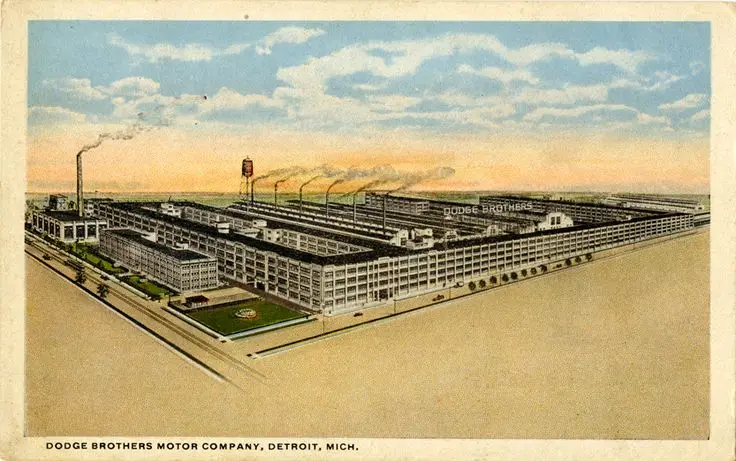

Dodge Brothers expanded rapidly after their successful introduction of the Model 30. Meanwhile, Chevrolet grew under General Motors’ ownership to challenge Ford’s market dominance.

Luxury manufacturers thrived as well. Packard Motor Car Co. gained prestige for their high-quality vehicles, while Lincoln (acquired by Ford in 1922) established itself as a premier luxury brand.

William Durant formed Durant Motors in 1921 after leaving GM, adding to Detroit’s diverse automotive landscape. Hudson and Chalmers also contributed to the city’s manufacturing ecosystem.

By 1929, Detroit produced about 80% of all American automobiles and was recognized worldwide as the Motor City.

Surviving the Great Depression

The Great Depression devastated Detroit’s automotive industry after the 1929 stock market crash. Production plummeted from 5.3 million vehicles in 1929 to just 1.3 million by 1932.

Smaller manufacturers struggled most severely. Chalmers merged with Chrysler, while Durant Motors closed entirely in 1933. Even industry giants faced existential threats.

Workers endured massive layoffs and wage cuts. Unemployment in Detroit reached nearly 50% at the Depression’s worst point.

Packard survived by introducing their more affordable 120 model, while Cadillac maintained operations through General Motors’ financial stability.

By the late 1930s, the industry began recovering as New Deal programs stimulated the economy. Car design evolved with innovations in manufacturing and design, setting the stage for Detroit’s incredible production achievements during World War II.

Twentieth-Century Challenges

Detroit’s journey as the Motor City faced significant hurdles throughout the 1900s. Economic shifts, global conflicts, and social issues reshaped the automotive landscape and tested the city’s resilience as a manufacturing powerhouse.

Impact of World War II on Car Manufacturing

When World War II erupted, Detroit’s auto factories underwent a dramatic transformation. The massive factory buildings that once produced family cars shifted to manufacturing military vehicles, weapons, and aircraft parts.

President Roosevelt called Detroit the “Arsenal of Democracy” as production lines that once made Model Ts now created tanks and bombers. Companies like Ford, Chrysler, and General Motors converted nearly 100% of their capacity to the war effort.

This transition wasn’t simple. Auto workers needed retraining, and new equipment had to be installed rapidly. Women entered the factories in unprecedented numbers, changing workplace demographics dramatically.

By war’s end, Detroit had proven its manufacturing might. The city produced over 25% of all U.S. military equipment, solidifying its reputation as America’s industrial backbone.

Post-War Boom and the Middle Class

After WWII, Detroit experienced an extraordinary economic surge. Auto production skyrocketed as factories returned to civilian manufacturing and Americans eagerly purchased new vehicles after years of rationing.

This hub for automobile manufacturing helped create America’s middle class. Union jobs at the Big Three automakers provided stable wages, benefits, and pensions that allowed workers to buy homes and send children to college.

Car ownership itself transformed American society. Suburbs expanded as workers could commute from homes outside city centers. The interstate highway system, developed in the 1950s, further accelerated this trend.

Detroit reached peak prosperity in the late 1950s with nearly 2 million residents. The city’s median income was among the highest nationally, and its automotive innovations dominated global markets.

Social Issues and Racial Tensions

Despite economic success, Detroit struggled with deep social divisions. The automotive industry’s relationship with Black workers was complicated, offering opportunities but within a segregated system.

Though Henry Ford had hired Black workers since the 1910s, discrimination remained prevalent. Black employees typically received the most harsh, exhausting, and degrading jobs on assembly lines. Housing segregation intensified as the city grew.

These tensions erupted in the 1943 and 1967 race riots. The 1967 uprising left 43 dead and accelerated “white flight” to suburbs, shrinking Detroit’s tax base and beginning a long urban decline.

Auto companies began relocating factories outside the city center, seeking cheaper land and newer facilities. This shift reduced job opportunities for city residents and furthered economic segregation.

By the 1970s, Detroit remained synonymous with America’s car industry but was increasingly divided by race and class, setting the stage for greater challenges ahead.

Decline and Resurgence

Detroit’s automotive industry faced dramatic challenges in recent decades, experiencing severe decline before showing signs of recovery. The city’s identity as the Motor City was tested through economic upheaval, corporate bankruptcies, and eventual reinvention.

Struggles with Globalization and Market Changes

The decline of Detroit’s auto industry began in the 1970s when foreign competitors, particularly from Japan, entered the U.S. market with fuel-efficient vehicles. This happened just as the oil crisis hit Americans hard, changing consumer preferences overnight.

The Big Three (General Motors, Ford, and Chrysler) struggled to adapt to these market changes. Their focus on larger vehicles with higher profit margins left them vulnerable when gas prices soared.

By the 1980s, Detroit manufacturers had lost significant market share. The city that once represented American industrial might saw its factories closing, including the massive Packard Motor Car factory that had operated since 1903.

Globalization accelerated the decline as automakers moved operations overseas to reduce costs. This shift devastated Detroit’s economy, with thousands of manufacturing jobs disappearing.

Bankruptcy and the Auto Industry Bailout

The 2008 financial crisis pushed Detroit’s struggling automakers to the breaking point. General Motors and Chrysler filed for bankruptcy in 2009, marking a historic low point for the American auto industry.

The federal government stepped in with a controversial $80 billion Automotive Industry Bailout. This decision sparked intense political debate, with some arguing against government intervention.

Mitt Romney, whose father George Romney had once led American Motors Corporation, famously opposed the bailout with a New York Times op-ed titled “Let Detroit Go Bankrupt.”

The bailout ultimately saved an estimated 1.5 million jobs and prevented complete collapse of the industry. However, Detroit’s population continued declining as unemployment and poverty rates soared.

Reinvention and Modern Challenges

Since 2010, Detroit’s auto industry has shown remarkable resilience. The Big Three restructured operations, focused on fuel efficiency, and embraced new technologies like electric vehicles and autonomous driving.

The resurgence of Motor City brought renewed investment to the region. Ford’s purchase and renovation of Michigan Central Station symbolizes Detroit’s potential rebirth.

Modern challenges remain significant. Competition from Tesla and foreign manufacturers continues to pressure traditional automakers. The transition to electric vehicles requires massive investment and workforce retraining.

Detroit’s automotive companies must balance innovation with profitability. The industry now employs fewer workers but demands higher skills, creating both opportunities and obstacles for local residents.

Climate change regulations and shifting consumer preferences continue to reshape what was once America’s most dominant industry.

Detroit’s Automotive Legacy and Future

Detroit’s rich automotive history shaped America’s economy and culture. The city’s car manufacturing legacy encompasses iconic buildings, societal transformation, and continues to evolve through modern innovation.

Architectural Heritage of the Packard Plant

The Packard Plant stands as a towering symbol of Detroit’s automotive golden age. Built in 1903, this massive 3.5-million-square-foot complex once represented the height of American industrial architecture.

The Packard Motor Car Company produced luxury vehicles here until 1956, employing thousands of workers at its peak. After Packard’s closure, the plant housed various businesses until the 1990s.

Today, the largely abandoned complex has become both a symbol of Detroit’s decline and potential rebirth. Spanish developer Fernando Palazuelo purchased the property in 2013 with ambitious renovation plans, though progress has been limited.

The plant’s distinctive reinforced concrete structures, designed by architect Albert Kahn, pioneered industrial building techniques. These architectural innovations later influenced factory designs worldwide.

Impact on the Rise of the American Middle Class

Detroit’s automotive industry fundamentally transformed America’s social structure by creating pathways to middle-class prosperity. Henry Ford’s revolutionary assembly line in 1913 not only changed manufacturing but also society itself.

Ford’s famous $5-a-day wage program doubled the standard industrial wage, allowing workers to afford the very products they built. This created a new consumer class practically overnight.

The United Auto Workers union, formed in the 1930s, secured better working conditions, healthcare, and pensions for automotive workers. These benefits became a model for middle-class employment nationwide.

Automotive jobs provided economic mobility for waves of immigrants and migrants, including European immigrants and African Americans during the Great Migration. Car manufacturing created stable employment that supported families for generations.

Transformation into a Modern Auto Manufacturing Hub

Detroit’s automotive industry has evolved dramatically from its mid-century peak. After decades of decline and the 2008-2009 industry crisis, the city is experiencing notable reinvention through technology and innovation.

Major manufacturers have invested billions in modernizing Detroit facilities. General Motors’ Factory ZERO (formerly Detroit-Hamtramck) now focuses exclusively on electric vehicle production after a $2.2 billion renovation.

The industry increasingly emphasizes autonomous vehicle technology, with testing centers and innovation hubs emerging throughout the region. Traditional automotive companies now collaborate with tech firms, changing the industry’s fundamental nature.

Detroit’s automotive future depends on adapting to sustainability demands. Electric vehicles, battery production, and alternative mobility solutions represent key growth areas.

Workforce development programs now train employees in advanced manufacturing skills, ensuring Detroit’s automotive talent remains competitive in a changing industry landscape.

Resources and Infrastructure

Detroit’s rise as the automotive center of America was significantly shaped by Michigan’s abundant natural resources and strategic location. The city had critical access to raw materials and transportation networks that made it ideal for car manufacturing.

Michigan’s Timber and Natural Resources

Michigan’s vast forests provided essential timber for early car manufacturing. In the early 1900s, wooden components were crucial in automobile production, with car frames, wheels, and dashboards all requiring quality hardwood.

The state’s rich forests supplied oak, maple, and ash – woods prized for their strength and durability in vehicle construction. Early Michigan automakers could source these materials locally, reducing costs and production time.

Beyond timber, Michigan offered other natural advantages. The state’s abundant clay deposits supported foundry operations needed for engine casting. Local sand was perfect for making glass, another essential component in car manufacturing.

This proximity to raw materials gave Detroit-based manufacturers a significant competitive edge over potential rivals in other regions.

The Mesabi Range and Iron Ore

The Mesabi Range in Minnesota became crucial to Detroit’s success, providing the iron ore necessary for steel production. This range represented one of North America’s richest iron deposits, fueling Detroit’s growing automotive industry.

Great Lakes shipping routes connected Detroit directly to these iron ore sources. Large ore carriers could transport massive quantities cheaply across Lake Superior and down to Detroit’s manufacturing plants.

By 1913, when Ford introduced the moving assembly line, steady iron ore supplies were essential to maintain production. The steel made from this ore formed the backbone of America’s automotive industry.

Detroit’s proximity to these resources helped transform it from a second-tier industrial city to the world’s automotive capital.

Water Routes and Heavy Industry

Detroit’s position on the Detroit River provided invaluable water transportation advantages. The city sat at the heart of the Great Lakes system, giving manufacturers access to an efficient shipping network.

These water routes allowed:

- Easy import of raw materials (iron ore, coal, rubber)

- Cost-effective export of finished vehicles

- Connection to major markets via the St. Lawrence Seaway

The river’s depth accommodated large cargo vessels, essential for heavy industry. Coal from Pennsylvania and West Virginia arrived by water, powering Detroit’s factories and steel mills.

This strategic location also attracted skilled workers and supporting industries. Tool and die makers, glass manufacturers, and textile producers all established operations near Detroit’s automotive plants.

The combination of water access and transportation infrastructure created the perfect environment for Detroit to remain synonymous with America’s car industry through both booms and busts.

Cultural and Economic Impact

Detroit’s evolution as the Motor City transformed American culture and the global economy in profound ways. The auto industry’s influence reached far beyond factory walls, reshaping society and creating lasting legacies.

Detroit and Silicon Valley: Cross-Pollination of Ideas

The relationship between Detroit and Silicon Valley has grown increasingly important in recent decades. As technology became central to automobile manufacturing, both regions began sharing innovation strategies.

Detroit’s engineering expertise combined with Silicon Valley’s software prowess created new possibilities for transportation. This cross-pollination became especially visible after 2010, when automakers opened research centers in California.

Companies like Ford and General Motors established innovation hubs in Silicon Valley to tap into tech talent. Meanwhile, Silicon Valley companies like Google and Apple invested in automotive projects, bringing their user-centered design approach to cars.

This exchange of ideas accelerated the development of electric vehicles, autonomous driving systems, and connected car technologies. The collaboration helped traditional automobile manufacturers adapt to changing consumer expectations in the digital age.

Automotive Executives and their Legacy

Key automotive executives shaped not just their companies but American business culture. Henry Ford’s introduction of the assembly line and $5 daily wage revolutionized manufacturing and middle-class life.

Alfred Sloan of General Motors created the modern corporate structure that businesses still use today. His system of decentralized operations with centralized policy control became a model for large organizations worldwide.

During the Great Depression, these executives worked with New Deal programs to help stabilize the economy. Their factories later became crucial to the “Arsenal of Democracy” during World War II.

Lee Iacocca saved Chrysler from bankruptcy in the 1980s and became a celebrity CEO, writing bestselling books and appearing in commercials. His leadership style influenced a generation of business leaders across industries.

The Making of a Global Icon

Detroit earned its “Motor City” nickname through cultural and economic dominance. The city’s reputation spread worldwide as car manufacturing in Michigan became synonymous with American industrial might.

Detroit’s automobiles appeared in movies, music, and literature, cementing the city’s iconic status. Motown music, named after the Motor City, created a soundtrack that celebrated Detroit’s industrial success and spread its cultural influence.

The annual Detroit Auto Show became a global event, drawing international attention and showcasing American engineering prowess. Automotive design from Detroit influenced fashion, architecture, and product design around the world.

Even as the city faced economic challenges in later decades, its cultural legacy remained powerful. Detroit’s identity as the birthplace of mass automobile production made it a symbol of both American industrial achievement and the challenges of deindustrialization.

Innovators and Pioneers

Detroit’s rise as the automotive capital emerged through the vision and determination of several key individuals who shaped modern car manufacturing. These pioneers developed revolutionary production methods and created iconic American automobile brands that would define an industry.

Ransom Olds and the Curved Dash Runabout

Ransom Eli Olds stands as one of Detroit’s earliest automotive innovators. In 1901, he introduced the Curved Dash Runabout, America’s first mass-produced automobile. This simple, affordable vehicle sold for $650 (equivalent to about $21,000 today).

The Curved Dash‘s production marked a pivotal moment in automotive history. Olds implemented an early version of the assembly line, where cars moved from one station to another during construction. This method dramatically increased production efficiency.

By 1904, Olds Motor Works was producing 5,000 cars annually—an impressive number for the era. The Curved Dash’s reliability and accessibility helped demonstrate that automobiles could be practical transportation for ordinary Americans, not just playthings for the wealthy.

The Leland Legacy: Cadillac and Lincoln

Henry Leland’s influence on automotive manufacturing can’t be overstated. After departing from Olds, Leland founded Cadillac in 1902, bringing precision engineering to automotive production.

Leland implemented standardized parts and careful quality control—revolutionary concepts at the time. His commitment to exactness earned Cadillac the prestigious Dewar Trophy in 1908 when three Cadillacs were disassembled, their parts mixed, and successfully reassembled without issues.

After selling Cadillac to General Motors, Leland established Lincoln Motor Company in 1917. Originally manufacturing Liberty aircraft engines for World War I, Lincoln soon transitioned to luxury automobiles.

Ford Motor Company acquired Lincoln in 1922, but Leland’s legacy of precision engineering and luxury continues to influence both brands today. His focus on quality established Detroit’s reputation for automotive excellence.

Briscoe Brothers and Beyond

Benjamin and Frank Briscoe brought financial expertise and manufacturing knowledge to Detroit’s budding automotive scene. In 1907, they established the Briscoe Manufacturing Company, which initially supplied sheet metal components to other automakers.

The brothers later founded the Maxwell-Briscoe Motor Company, producing moderately priced cars for the growing middle class. Their innovative marketing strategies included offering cars in colors beyond basic black—a novelty at the time.

Benjamin Briscoe attempted to create the United States Motor Company in 1910, envisioning a conglomerate to rival General Motors. Though this venture ultimately failed, it demonstrated the rapid evolution of the industry toward consolidation.

The Briscoes’ willingness to experiment with business models and manufacturing techniques helped establish Detroit as a center for automotive innovation beyond just technical advancement.

Henry Leland and the REO Car Company

After leaving Oldsmobile in 1904 following a dispute with investors, Ransom Olds established the REO Motor Car Company (named using his initials). The company quickly became known for reliability and quality.

REO produced both passenger cars and commercial vehicles. The REO Speed Wagon, introduced in 1915, became one of America’s most successful commercial vehicles and later inspired the name of the famous rock band.

Olds applied lessons from his earlier ventures, implementing improved assembly techniques and focusing on middle-market vehicles. REO weathered the Great Depression better than many competitors.

Though REO eventually ceased automobile production in 1936 to focus on trucks, Olds’ second major automotive venture demonstrated his adaptability and continued influence on Detroit’s automotive industry. His manufacturing innovations continued to shape how cars were built throughout the industry.

Frequently Asked Questions

Detroit’s automotive history has shaped American industry for more than a century. The city’s rise and fall as the car manufacturing capital reveals important economic and social patterns that continue to influence the region today.

What factors contributed to the rise of Detroit as a center for automobile manufacturing?

Detroit became a manufacturing hub due to its strategic location near raw materials like steel and rubber. The city had excellent transportation networks including waterways and railroads that made shipping efficient.

Local talent and engineering expertise drew early automobile pioneers to the area. Financial backers in Detroit were willing to invest in the emerging auto industry during the late 1800s and early 1900s.

The auto industry in Detroit began in the 1890s with early innovators like Charles Brady King and R.E. Olds. These pioneers established the foundation for what would become America’s automotive center.

How did the automobile industry shape the economy and culture of Detroit in the 1950s?

The 1950s represented the golden age of Detroit’s auto industry with record-breaking car production and sales. The Big Three automakers—Ford, General Motors, and Chrysler—created hundreds of thousands of well-paying jobs.

Strong unions ensured workers received good wages, helping create a robust middle class in the city. This economic prosperity shaped Detroit’s culture, with car-centered design visible in architecture, entertainment, and daily life.

The automotive boom led to suburban expansion as workers could afford homes and commute by car. Detroit’s population peaked during this era, reflecting the industry’s powerful economic influence on urban development.

What were the main reasons behind the decline of car manufacturing in Detroit?

Foreign competition, especially from Japanese automakers, eroded Detroit’s market dominance starting in the 1970s. Many manufacturers failed to innovate quickly enough or match the fuel efficiency and reliability of imported vehicles.

Automation reduced the need for large workforces, shrinking employment even as production continued. Detroit experienced devastating economic consequences when plants closed or relocated to areas with lower labor costs.

Poor management decisions and inflexible union agreements made it difficult for companies to adapt to changing market conditions. The 2008 financial crisis dealt another severe blow, forcing major restructuring and government bailouts.

Which major car manufacturers were originally based in Detroit and how did they impact the city?

Ford Motor Company, founded in Detroit in 1903 by Henry Ford, revolutionized manufacturing with the assembly line. Ford’s $5 daily wage transformed worker expectations and helped create a new middle class.

General Motors, formed in 1908, grew to become the world’s largest automaker for many decades. Chrysler, established in 1925, completed what became known as Detroit’s “Big Three” manufacturers.

The Dodge brothers, who initially invested in Ford, later established their own successful company. These companies built massive industrial complexes that defined Detroit’s landscape and economy for generations.

How has the automobile industry’s transformation affected the social and economic landscape of Detroit?

Deindustrialization led to widespread unemployment and population decline. Many neighborhoods experienced abandonment as residents left to find work elsewhere.

City tax revenues plummeted, making it difficult to maintain infrastructure and services. Detroit filed for bankruptcy in 2013, the largest municipal bankruptcy in U.S. history.

The city’s demographic makeup changed significantly as middle-class families moved to suburbs. Communities surrounding former manufacturing sites have faced environmental challenges from industrial contamination.

What are the current trends and future prospects for car manufacturing in Detroit?

Detroit has seen a modest revival in automotive manufacturing with companies investing in modernized facilities. The focus has shifted toward electric vehicles, autonomous driving technology, and software development.

The city now hosts technology companies alongside traditional manufacturers. This diversification helps create resilience against future industry disruptions.

Detroit’s automotive legacy remains a key part of its identity even as the industry evolves. Educational institutions are developing programs to train workers for high-tech manufacturing and mobility-related fields.