Riding a motorcycle with a damaged frame can be dangerous and lead to unpredictable handling. Many riders overlook frame issues when buying used bikes or after minor accidents, focusing instead on cosmetic damage. The best way to diagnose a bent motorcycle frame is through a combination of visual inspection and alignment checks that compare the positioning of your wheels and key frame components.

A proper frame inspection doesn’t require expensive equipment, but it does demand attention to detail. Look for telltale signs like unusual wear patterns on tires, difficulty keeping the bike tracking straight, or visible cracks near weld points. You can perform basic alignment checks at home by measuring from the swing arm pivot to the rear axle and comparing wheel alignment from front to back, as this helps identify if your frame is twisted or bent.

Key Takeaways

- Regular frame inspections can identify hidden damage that might compromise motorcycle safety and handling.

- Visual checks for cracks, bends, and rust should be combined with measurements to verify wheel alignment.

- Unusual riding sensations or handling issues often indicate frame problems requiring professional assessment.

Why Checking Your Motorcycle Frame for Damage Matters

The frame is your motorcycle’s backbone, providing structural integrity and ensuring proper handling on the road. Damage to this critical component can lead to severe consequences affecting your safety, bike performance, and financial well-being.

Risks of Riding with a Damaged Frame

A bent or damaged motorcycle frame significantly increases accident risk. Even minor frame damage can cause unpredictable handling, particularly at higher speeds. This instability often manifests as wobbling, pulling to one side, or unusual vibrations.

Frame issues compromise critical alignments in your motorcycle’s components. When the frame is bent:

- Wheels may track improperly

- Suspension components work against each other

- Steering becomes less responsive

- Weight distribution shifts unnaturally

These problems worsen over time. What begins as a slight wobble can deteriorate into catastrophic failure. Many serious motorcycle accidents stem from undiagnosed frame damage that could have been addressed early.

When buying a used motorcycle, thorough frame inspection is especially crucial as previous damage may be hidden under fresh paint or cosmetic repairs.

Impact on Safety and Performance

Frame damage directly impacts rider safety through compromised handling and stability. When your frame isn’t straight, your motorcycle cannot perform as designed.

The effects include:

- Unpredictable cornering making it difficult to maintain your intended line

- Inconsistent braking that may pull to one side under hard stops

- Premature tire wear due to improper wheel alignment

- Increased stress on connected components

Performance suffers even during routine riding. You’ll likely notice increased effort required to steer and maintain control. Professional measurements often reveal issues before they become dangerous.

Even after minor drops, checking your frame should be standard practice. What appears as minor cosmetic damage could indicate more serious structural issues.

Legal and Insurance Considerations

Riding a motorcycle with a damaged frame may violate road safety regulations in many jurisdictions. This puts you at legal risk during routine traffic stops or following an accident.

Insurance companies take frame damage seriously. If you’re in an accident:

- Your claim might be denied if pre-existing frame damage contributed

- The motorcycle might be declared a total loss

- Your premium could increase significantly

When selling your motorcycle, undisclosed frame damage constitutes fraud in most places. Buyers can pursue legal action if they discover issues later.

Repair bills for frame damage are typically substantial. Many insurers consider frame repairs economically unfeasible, preferring to write off the motorcycle entirely. This makes prevention and early detection crucial for avoiding financial losses.

Tools and Preparation for Frame Inspection

A thorough motorcycle frame inspection requires specific tools, proper setup, and basic knowledge of motorcycle geometry. The right preparation helps identify problems that might not be visible at first glance.

Essential Tools for Checking Frame Damage

A quality straight edge or ruler is crucial for measuring alignment and detecting bent sections. This simple tool helps identify frame issues by checking if surfaces are truly flat.

Tape measure (preferably metal) allows you to check critical dimensions and compare measurements from side to side. Keep it handy for measuring distances between key points.

Laser level helps determine if components are properly aligned. This tool provides accurate readings when checking if the frame is twisted or warped.

Other helpful tools include:

- Digital calipers for precise measurements

- Plumb bob for checking vertical alignment

- Flashlight for inspecting hard-to-see areas

- Camera to document findings

- Notepad to record measurements

Setting Up a Safe Inspection Environment

Choose a well-lit workspace with enough room to move around the entire motorcycle. Proper lighting helps spot subtle cracks and alignment issues.

A level surface is essential for accurate measurements. Concrete floors work best, but any flat, stable surface will do if checked with a level first.

Use a motorcycle stand to elevate the bike and keep it stable. This allows better access to the underside and makes it easier to check wheel alignment.

Remove fairings or bodywork that might obstruct your view. This extra step exposes frame sections that are normally hidden and provides better access to key measurement points.

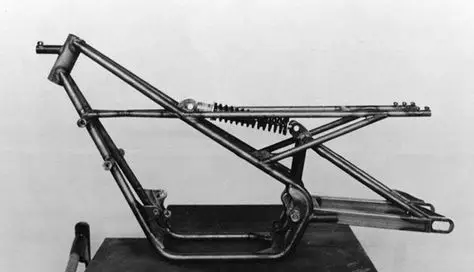

Understanding Motorcycle Geometry

Frame geometry affects how a motorcycle handles and performs. Key measurements include wheelbase, rake (steering head angle), and trail.

The offset between the front and rear wheels should be consistent with manufacturer specifications. Any deviation can indicate frame twist or misalignment.

Check that both wheels track in a straight line when aligned properly. This can be verified by measuring from a fixed point on the frame to each wheel or using a string test.

Understanding these geometric principles helps inspectors recognize when something is wrong. Even small deviations from factory specifications can significantly impact handling and safety.

Proper frame geometry ensures the motorcycle tracks straight and handles as designed. Recognizing normal geometry makes identifying abnormal bends or twists much easier.

Visual Inspection Techniques for Frame Damage

Examining a motorcycle frame requires a methodical approach to spot damage that might affect safety and performance. A careful inspection can reveal issues before they lead to more serious problems on the road.

Identifying Signs of Frame Damage

Start by placing the motorcycle on a level surface and examining the frame from multiple angles. Look for obvious signs like cracks, bends, or rust that might indicate structural weakness.

Dents or deformations in the frame tubes are clear indicators of past impacts. Check if the motorcycle sits evenly on both wheels – uneven stance often points to alignment issues.

Use a straight edge or string line along the frame rails to detect subtle bends that aren’t immediately visible. Compare symmetrical parts from side to side – they should mirror each other perfectly.

Look for fresh scratches or impact marks that might indicate a recent accident. Pay special attention to stress points where the frame connects to the engine mounts and suspension components.

Assessing Welds, Joints, and Paint

Examine all welds and joints carefully as these are common failure points. Quality welds should appear smooth and consistent without bubbles, gaps, or excessive material.

Look for cracks or separations in the welded areas, especially at stress points like the steering head, engine mounts, and swingarm pivot. A magnifying glass can help spot hairline fractures.

Pay attention to paint disruptions around frame members. Cracked paint or bubbling often indicates underlying structural issues. Fresh paint in specific areas might be hiding repairs.

Check for rust around joints and mounting points – corrosion can severely weaken these critical areas. Tap suspicious areas gently with a small hammer; a dull sound may indicate internal damage not visible from outside.

Spotting Bent Forks and Rake Issues

Inspect the front forks by standing directly in front of the motorcycle. Both forks should be perfectly parallel to each other and perpendicular to the ground when viewed head-on.

Check the rake angle (the angle between the steering head and vertical plane) as incorrect angles affect handling. Bent forks typically show oil leakage around seals and uneven wear on the front tire.

Test the steering by turning the handlebars from lock to lock – movement should be smooth without binding or unusual resistance. Watch for fork tubes that appear twisted or misaligned.

Measure the distance from each fork tube to a fixed point on the front wheel. Any significant difference indicates fork damage. Look for scoring or pitting on the chrome surfaces of the fork tubes, which can damage seals.

Hands-On Checks and Alignment Assessment

Physical inspection is crucial for identifying motorcycle frame damage that might not be visible at first glance. These hands-on methods help detect bends, twists, and misalignments that can affect handling and safety.

Using a Straight Edge to Detect Misalignment

A straight edge is an essential tool for checking frame alignment. Place a metal ruler or dedicated straight edge against the motorcycle’s frame rails to spot any gaps or irregular contact points. These gaps indicate potential bends in the frame structure.

For best results, check multiple points along the frame:

- Main frame rails (both sides)

- Neck/steering head area

- Connection points between main frame and subframe

If the straight edge doesn’t make consistent contact along critical points, it suggests frame damage. Take measurements from identical points on both sides of the bike and compare them.

When checking the steering head area, look for any asymmetry. This area often shows damage after front-end collisions and can dramatically affect handling.

Checking Wheel Alignment and Offset

Proper wheel alignment is critical for safe motorcycle operation. Start by placing the bike on level ground with both wheels straight.

Use a long string method to check alignment:

- Stretch string along both sides of the wheels

- Measure distance from string to rim at multiple points

- Compare measurements from front to rear

The string should touch both tires equally at front and rear points. Any variation indicates misalignment. When measuring offset, check that the rear wheel aligns properly with the front wheel.

Check the swing arm pivot to rear axle distance on both sides. These measurements should match exactly. Differences suggest the swing arm or frame is bent.

Inspecting the Subframe for Bends

The subframe supports the seat, rear bodywork, and sometimes the passenger. This component often bends in crashes even when the main frame remains intact.

To inspect the subframe:

- Remove seat and bodywork for clear access

- Check mounting points for cracks or elongated bolt holes

- Compare measurements from center to identical points on both sides

Use a tape measure to verify the subframe’s symmetry. Measure from the center point to fixed reference points on both sides—these should match exactly.

Look for any visible kinks or bends in the subframe tubes. Even slight deformations can cause improper weight distribution and handling issues. Most subframe damage occurs at mounting points, so pay special attention to these areas.

When to Seek Professional Help

While basic inspections can identify obvious frame damage, some issues require expert assessment and specialized equipment. Knowing when to consult a professional can save you from costly repairs or dangerous riding conditions.

Understanding the Limits of DIY Inspection

DIY inspections have clear limitations when checking for motorcycle frame damage. If your bike has been in a high-speed accident, the frame may have significant damage that isn’t visible to the untrained eye.

Complex issues like hairline cracks, internal stress fractures, and subtle misalignments often escape detection during casual inspections. These problems require professional measurement tools and expertise.

Warning signs that indicate professional help is needed:

- Frame shows visible bending or warping

- Motorcycle handles differently after an accident

- Unusual tire wear patterns appear

- Persistent alignment issues despite adjustments

The cost of a professional inspection might seem high, but it’s minimal compared to the potential repair bill for catastrophic frame failure while riding.

Choosing a Qualified Motorcycle Technician

Finding the right professional for frame inspection requires research and attention to credentials. Meticulous measurements by professionals provide the most accurate assessment of frame damage.

Look for technicians with specific experience in motorcycle frame inspection and repair. Frame specialists typically have:

- Certification from recognized industry bodies

- Specialized alignment and measurement equipment

- Experience with your specific motorcycle make and model

- Positive reviews from other riders

Before committing, ask the technician about their inspection process. They should be able to explain their methodology for detecting hidden damage.

Request a detailed written report of their findings. This documentation proves valuable for insurance claims and can help determine if repairs are economically viable compared to replacement costs.

What to Do After Identifying Frame Damage

Once you’ve discovered damage to your motorcycle frame, you need to make important decisions about repairs, insurance, and safety. Taking the right steps can save you money and ensure your safety when you get back on the road.

Deciding Between Repair and Replacement

Frame damage severity determines your best course of action. Minor bends or cracks in non-critical areas might be repairable by professional welders. These repairs typically cost between $300-$1,000 depending on complexity.

Complete replacement becomes necessary when:

- The frame has multiple fracture points

- Critical load-bearing sections are compromised

- The frame is twisted beyond correction

- Repair costs exceed 70% of replacement value

Replacement frames typically cost $800-$2,500 plus labor. Always consult multiple motorcycle frame specialists before deciding.

Factory-authorized repair shops often provide detailed estimates with parts breakdowns. Keep all repair bills for insurance and resale documentation.

Navigating Insurance Claims and Salvage Titles

Filing an insurance claim for frame damage requires thorough documentation. Take detailed photos of all damage before repairs begin. Insurance companies often send adjusters to verify damage in person for costly frame repairs.

Be aware that significant frame damage may result in:

- Total loss designation

- Reduced settlement offers

- Salvage title issuance

A salvage title permanently affects the motorcycle’s value and insurability. Some insurers won’t cover salvage-titled motorcycles, while others charge premium rates.

If disputing an insurance valuation, gather evidence of pre-accident condition and comparable motorcycle values. Independent appraisals strengthen your position during negotiations.

Safety Checks Before a Test Ride

After frame repairs, thorough safety verification is essential before riding. Start with a complete wheel alignment check – both wheels must track in the same plane without vertical tilting.

Critical pre-ride safety checks include:

- Steering head bearings: Test for smooth movement without binding

- Suspension mounting points: Verify proper alignment and torque

- Chain/belt alignment: Ensure perfect tracking

- Brake component mounting: Check for true alignment

Test the motorcycle at low speeds in an empty parking lot first. Pay attention to how it handles during gentle turns and stops. Any pulling to one side indicates remaining alignment issues.

Never attempt high-speed or aggressive riding until confident in the repair integrity after several hundred miles of cautious riding.

Preventing Future Frame Damage

Protecting your motorcycle frame requires both proactive maintenance and smart riding practices. A well-maintained frame extends your motorcycle’s lifespan and ensures your safety on the road.

Regular Maintenance and Inspections

Establish a consistent maintenance schedule to check your motorcycle frame for early signs of damage. Every three months, thoroughly clean the frame to remove dirt and debris that might hide cracks or corrosion.

Inspect frame mounting points and welds regularly. These areas experience the most stress and are prone to developing problems first.

Apply protective coatings designed for motorcycle frames to prevent rust and corrosion. Quality rust inhibitors create a barrier against moisture and road salt.

Keep fasteners and bolts at proper torque specifications. Loose components can cause frame stress over time, leading to alignment issues or structural weakening.

Document all inspections with photos to track any developing issues. This visual record helps identify gradual changes that might otherwise go unnoticed.

Safeguarding Against Motorcycle Crashes

Install quality frame sliders or crash bars to absorb impact during falls. These protective accessories can prevent direct damage to the frame in minor accidents.

Practice defensive riding techniques to avoid collision situations. Maintaining safe distances and staying alert dramatically reduces crash risks.

Consider advanced rider training courses that teach emergency maneuvers. These skills help riders avoid accidents that could result in frame damage.

Store your motorcycle properly when not in use. Use a quality motorcycle cover and keep it in a sheltered location away from extreme weather conditions.

Avoid modifications that place undue stress on the frame. Non-standard components or improper installations can compromise the frame’s structural integrity.

Frequently Asked Questions

Motorcycle frame damage inspection requires specific knowledge about key indicators and proper techniques. Frame integrity is critical for rider safety and motorcycle performance.

What are the signs of damage to look for when inspecting a motorcycle frame?

Look for visible cracks, bends, or distortions in the frame structure. These issues can appear as hairline fractures or more obvious deformations.

Check for rust or stress signs in the subframe area, which might indicate hidden damage.

Examine welds for any separation or cracking. Damaged welds are dangerous weak points that can lead to catastrophic failure.

Misalignment of components like wheels, handlebars, or footpegs often indicates frame damage. If these parts don’t align properly, the frame may be compromised.

What methods are used to determine if a motorcycle frame is bent?

String alignment tests involve stretching string from the front to rear wheel to check if the motorcycle tracks straight. Deviations indicate frame issues.

Professional measurement involves meticulous measurements of key frame points. This method requires removing bodywork for complete access.

Laser alignment tools can detect even minor frame deviations. These professional-grade tools provide precise readings of frame straightness.

Visual comparison with manufacturer specifications helps identify discrepancies in frame geometry. Reference points should match factory measurements.

Which tools are required for checking motorcycle frame alignment and straightness?

Basic inspection requires a straight edge, tape measure, and level. These allow for preliminary checks of obvious alignment issues.

String or fishing line serves as an inexpensive tool for checking wheel alignment and frame straightness. This method works well for initial assessments.

Specialized motorcycle frame alignment tools include laser measuring devices and jigs. These provide the most accurate readings for serious inspections.

A flashlight with a focused beam helps detect small cracks in hard-to-see areas. Adequate lighting is essential for thorough visual inspection.

What steps should be taken for a thorough motorcycle frame inspection?

Start by cleaning the frame thoroughly to remove dirt, grease, and debris. This ensures small defects aren’t hidden.

Inspect all frame components systematically, including main frame, subframe, and mounting points. Be methodical to avoid missing problem areas.

Check wheel alignment by measuring the distance from each wheel to fixed frame points. Both sides should measure equally.

Examine steering head bearings by rocking the front end to detect looseness. Abnormal movement might indicate frame damage around the steering neck.

Can a damaged motorcycle frame be safely repaired, and how?

Minor damage like small dents or superficial scratches typically don’t affect structural integrity. These cosmetic issues generally don’t require repair.

Moderate damage may be repairable by professional frame specialists. This involves straightening, reinforcing, or rewelding compromised areas.

Severe frame damage often renders the motorcycle unsafe to ride. Many manufacturers recommend replacing rather than repairing severely damaged frames.

Professional repair requires specialized equipment including frame jigs, hydraulic presses, and welding apparatus. DIY repairs are not recommended for structural issues.

How can I tell if a used motorcycle has hidden frame damage?

Check the motorcycle’s history for accident records. Previous damage may indicate potential frame issues even if visually repaired.

Look for mismatched paint or signs of repair around key frame areas. These can indicate previous damage and repairs.

Professional inspection using penetrant testing can reveal hairline fractures invisible to the naked eye. This technique is borrowed from aerospace engineering.

Test ride the motorcycle to feel for handling abnormalities. A damaged frame often causes the motorcycle to pull to one side or handle unpredictably.