Formula 1 underwent one of its biggest changes in 2014 when the sport switched from naturally aspirated V8 engines to hybrid power units. This move transformed how F1 cars generate power and marked a new era focused on efficiency and sustainability. The introduction of hybrid engines revolutionized Formula 1 by combining traditional combustion engines with electric motors, creating the most efficient engines in the world while maintaining incredible performance.

The change brought new challenges and opportunities for teams and manufacturers. Engineers had to master complex energy recovery systems that capture power during braking and from exhaust gases. These systems allow drivers to deploy extra electrical power for overtaking and acceleration.

The hybrid era continues to evolve with major changes coming in 2026. New power unit regulations will triple the electrical power output and introduce 100% sustainable fuels. Six manufacturers including newcomers Audi and returning Honda will compete with these advanced power units that bridge the gap between racing technology and road cars.

Key Takeaways

- Hybrid power units replaced V8 engines in 2014, combining combustion engines with electric motors for better efficiency

- Energy recovery systems capture power from braking and exhaust to provide extra acceleration and overtaking opportunities

- The 2026 regulations will triple electrical power output and introduce fully sustainable fuels to attract more manufacturers

The Shift To Hybrid Power In Formula 1

Formula 1’s transition to hybrid power began in 2014 with new regulations that fundamentally changed motorsport. The FIA made this shift to attract manufacturers, improve sustainability, and align with automotive industry trends toward electrification.

Why The FIA Introduced Hybrid Power Units

The FIA introduced hybrid power units to make Formula 1 more relevant to the automotive industry. Road car manufacturers were developing hybrid technology for consumer vehicles. F1 needed to reflect these real-world innovations.

Environmental concerns also drove this decision. Traditional combustion engines were becoming outdated as the world focused on sustainability. Formula 1’s transition to hybrid power units aimed to align the sport with global automotive trends and promote sustainability.

The new regulations attracted major manufacturers who saw value in hybrid development. Companies could use F1 as a testing ground for technologies that would benefit their road cars.

Key motivations included:

- Attracting automotive manufacturers

- Improving fuel efficiency

- Reducing environmental impact

- Advancing hybrid technology development

The hybrid power units also maintained performance while using less fuel. This showed that efficiency and speed could work together.

Timeline Of Hybrid Power Adoption In F1

F1 first experimented with hybrid technology through KERS (Kinetic Energy Recovery System) in 2009. This early system was limited and not widely adopted by teams.

The current hybrid era began in 2014 with the introduction of 1.6-liter V6 turbocharged hybrid power units. These replaced the naturally aspirated V8 engines used previously.

Timeline of hybrid development:

- 2009: KERS introduced as optional system

- 2014: Mandatory hybrid power units implemented

- 2022: E10 fuel with 10% bio-components introduced

- 2026: New regulations with enhanced hybrid systems planned

The 2014 power units combined a combustion engine with an Energy Recovery System (ERS). This system harvests energy from braking and exhaust heat.

The 2026 regulations will feature more powerful hybrid systems with electrical power rising from 120kW to 350kW. Cars will also use 100% sustainable fuel.

Influence Of Major Manufacturers

Major automotive manufacturers played a crucial role in F1’s hybrid transition. Mercedes, Ferrari, and Renault were early adopters of the 2014 hybrid regulations.

Honda returned to F1 in 2015, partly attracted by the hybrid technology development opportunities. The Japanese manufacturer saw value in testing hybrid systems that could benefit their road car division.

Six manufacturers will participate from 2026, showing increased interest in hybrid F1 technology:

| Manufacturer | Status | Partner Team |

|---|---|---|

| Mercedes | Continuing | Mercedes |

| Ferrari | Continuing | Ferrari |

| Renault | Continuing | Alpine |

| Honda | Returning | Red Bull |

| Audi | New entry | Sauber |

| Ford | New entry | Red Bull Powertrains |

Audi and Ford represent new investments in F1 hybrid technology. These manufacturers were attracted by the 50-50 energy split between electric and combustion power planned for 2026.

The removal of the complex MGU-H component for 2026 also appealed to manufacturers. This change makes the power unit easier to develop and more relevant to road car technology.

How F1 Hybrid Power Units Work

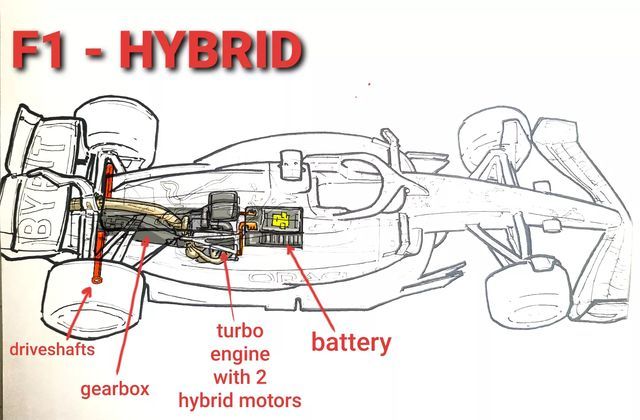

F1’s hybrid power units combine a 1.6-liter turbocharged engine with two electric motor generator units that capture energy from braking and exhaust heat. The system stores recovered energy in batteries and deploys it for extra power when needed.

Internal Combustion Engine & Turbocharging

The internal combustion engine forms the heart of every F1 power unit. Since 2014, F1 cars use 1.6-liter V6 direct-injection engines with single turbochargers.

These engines produce around 670 horsepower on their own. The V6 configuration uses six cylinders arranged in a V-shape at 90 degrees.

Key Engine Specifications:

- Displacement: 1.6 liters maximum

- Cylinders: 6 in V configuration

- Fuel injection: Direct injection only

- Rev limit: 15,000 RPM maximum

The turbocharger compresses air entering the engine. This creates more power from the smaller engine size. The turbo uses exhaust gases to spin a turbine that drives the compressor.

F1 engines achieve incredible efficiency ratings above 50%. This makes them the most efficient engines in the world for their power output.

MGU-K And Regenerative Braking

The MGU-K stands for Motor Generator Unit – Kinetic. This kinetic energy recovery system connects to the crankshaft and captures energy during braking.

When drivers brake, the MGU-K acts like a generator. It converts the car’s kinetic energy into electrical energy. This process is called regenerative braking.

The energy store (battery) holds this recovered energy until needed. Drivers can deploy up to 120 kW (161 horsepower) from the MGU-K for 33.3 seconds per lap.

MGU-K Specifications:

- Maximum power: 120 kW (161 hp)

- Energy per lap: 4 MJ maximum

- Deployment time: 33.3 seconds per lap

- Connection: Direct to crankshaft

The motor generator unit works both ways. It recovers energy under braking and provides extra power during acceleration. This dual function makes it essential for lap time performance.

MGU-H: Harnessing Heat Energy

The MGU-H (Motor Generator Unit – Heat) connects directly to the turbocharger shaft. It captures energy from exhaust gases that would otherwise be wasted as heat.

This electric motor can spin the turbocharger when exhaust flow is low. This eliminates turbo lag and keeps boost pressure consistent. The MGU-H also generates electricity when excess exhaust energy spins the turbo faster than needed.

Unlike the MGU-K, the MGU-H has no energy limits per lap. It can recover and deploy unlimited energy throughout each race. This makes it extremely valuable for performance.

The energy recovery system sends power from the MGU-H to either the energy store or directly to the MGU-K. This flexibility allows teams to optimize energy flow based on track conditions.

MGU-H Benefits:

- Eliminates turbo lag completely

- Provides unlimited energy recovery

- Improves engine response

- Increases overall efficiency

The MGU-H represents the most complex part of the hybrid system. Its ability to manage turbocharger behavior while generating electricity makes modern F1 engines incredibly responsive.

Performance And Efficiency Gains

Modern F1 hybrid power units achieve over 50% thermal efficiency while delivering instant torque through electric motors. These systems work with active aerodynamics to create performance advantages that traditional engines cannot match.

Thermal Efficiency Of Modern Power Units

F1’s hybrid power units represent the most efficient engines on the planet. Mercedes achieved a breakthrough when their M08 EQ Power+ power unit recorded thermal efficiency levels greater than 50% during dynamometer testing.

This efficiency comes from the integration of multiple energy recovery systems. The ERS-H harvests energy from exhaust gases through the turbocharger. The ERS-K captures kinetic energy during braking.

Key Efficiency Improvements:

- Thermal efficiency: Over 50% vs 35% for road cars

- Fuel consumption: 35% reduction compared to V8 engines

- Energy recovery: Up to 4 MJ per lap from braking and exhaust

The V6 turbo-hybrid units burn less fuel while producing similar power to the previous V8 engines. Teams can recover and deploy 160 horsepower for 33 seconds per lap through the ERS systems.

Torque And Throttle Response Improvements

Electric motors provide instant torque delivery that transforms how F1 cars accelerate. Unlike internal combustion engines, electric motors reach peak torque immediately from zero RPM.

The MGU-K (Motor Generator Unit-Kinetic) delivers additional power directly to the crankshaft. This creates seamless power delivery throughout the rev range. Drivers can access this extra power boost strategically during races.

Torque Characteristics:

- Electric motor torque: Instant delivery from 0 RPM

- Combined output: Over 1000 horsepower total system power

- Deployment time: 33 seconds of maximum ERS per lap

The hybrid system eliminates turbo lag through electric assistance. When drivers press the throttle, electric motors fill power gaps while the turbocharger spools up. This creates smoother acceleration out of corners.

Active Aerodynamics Integration

Modern F1 cars use DRS (Drag Reduction System) that works alongside hybrid power for maximum efficiency. The rear wing flap opens on straights to reduce drag when drivers deploy ERS power.

Active aerodynamics help hybrid systems work more effectively. Lower drag means less energy needed to maintain high speeds. Cars can save hybrid energy for crucial moments like overtaking or defending position.

Aerodynamic Benefits:

- DRS zones: Designated areas for drag reduction activation

- Energy savings: Reduced power needed at high speeds

- Strategic advantage: Combined with ERS deployment timing

The integration allows teams to optimize both aerodynamic and hybrid systems together. Engineers program energy deployment to match DRS availability on each track layout.

Key Technologies And Innovations

Formula 1’s hybrid revolution centers on three main technical areas: energy recovery systems that capture waste energy, advanced battery storage that manages power efficiently, and sophisticated software that controls energy flow. These hybrid systems combine raw combustion power with cutting-edge electrical performance to create the most efficient racing engines ever built.

KERS And Its Evolution

KERS first appeared in Formula 1 in 2009 as a basic energy recovery system. The original system captured kinetic energy during braking and stored it in a flywheel or battery.

Drivers could deploy this stored energy for an extra 60 kW of power for 6.7 seconds per lap. Many teams struggled with the early technology due to weight and reliability issues.

The system evolved dramatically when F1 introduced the current hybrid era in 2014. KERS became part of a much larger energy recovery system called ERS.

Modern ERS includes two main components:

- ERS-K: Recovers kinetic energy from braking

- ERS-H: Recovers thermal energy from exhaust gases

The new system can deploy 120 kW for 33 seconds per lap. This represents nearly double the power and five times the duration of the original KERS.

Teams now use advanced motor generator units that work as both motors and generators. These units can recover energy and provide power assistance seamlessly during races.

Advanced Batteries And Energy Stores

Modern F1 cars use lithium-ion battery packs as their primary energy store. These batteries must handle extreme charging and discharging cycles during races.

The FIA limits energy stores to 4 MJ capacity to keep costs controlled. Teams must balance battery weight, cooling requirements, and power delivery within these strict rules.

Key battery specifications include:

- Maximum voltage: 1000V

- Weight: Approximately 25-30 kg

- Charging rate: Up to 2 MJ per lap from ERS-H

- Discharge rate: 4 MJ per lap maximum

Battery management systems monitor cell temperatures constantly. Overheating can cause power loss or complete system failure during races.

Teams develop custom cooling systems to keep batteries at optimal temperatures. These systems use liquid cooling circuits integrated with the car’s main cooling system.

Energy density improvements allow teams to extract more performance from the same battery size. Modern batteries store significantly more energy than early hybrid systems while weighing less.

Software And Power Management

Power management software controls energy flow between the combustion engine, electric motors, and battery systems. This software makes hundreds of calculations per second during races.

Drivers can select different energy deployment modes through steering wheel controls. These modes change how aggressively the system uses stored electrical energy.

Software manages several critical functions:

- Battery charging and discharging rates

- Motor generator unit operation

- Energy recovery optimization

- Thermal management

Teams program strategies for energy use throughout each lap. The software automatically adjusts power delivery based on track conditions and race situations.

Advanced algorithms predict energy needs for upcoming track sections. This allows the system to save or deploy energy at the most effective times.

Real-time telemetry sends battery data back to pit crews. Engineers can monitor energy levels and adjust strategies during races based on this information.

Sustainability And The Future Of F1 Power Units

Formula 1’s commitment to sustainability centers on three major developments: the complete transition to sustainable fuels by 2026, direct technology transfer to road cars, and measurable reductions in environmental impact through hybrid systems.

100% Sustainable Fuels Adoption

The 2026 F1 engine regulations mandate a complete shift from the current E10 blend to 100% sustainable fuel. This represents the most significant fuel change in F1 history.

The new sustainable fuels come from three main sources: non-food biomass, municipal waste, and carbon capture technology. Each source must meet strict greenhouse gas reduction targets set by the FIA’s fuel certification program.

This change eliminates all fossil carbon emissions from F1 cars during races. The current E10 fuel contains only 10% ethanol, meaning 90% still comes from traditional petroleum sources.

Key Benefits:

- Zero fossil carbon emissions from racing

- Proven technology for road car adoption

- Reduced dependence on petroleum resources

The FIA has confirmed these sustainable fuel regulations are locked in for 2026, with all teams and manufacturers committed to the transition.

Influence On Road Car Technology

F1 hybrid technology directly influences everyday car development through energy recovery systems and battery management. The sport serves as a testing ground for technologies that later appear in consumer vehicles.

Regenerative braking systems developed in F1 now feature in most hybrid road cars. These systems capture energy during braking that would otherwise be lost as heat.

The 2026 regulations increase energy recovery from 4MJ to 8.5MJ per lap. This advancement pushes battery and energy management technology forward faster than traditional automotive development cycles.

| Technology | F1 Development | Road Car Application |

|---|---|---|

| Battery Management | Real-time optimization | Extended EV range |

| Energy Recovery | 8.5MJ per lap by 2026 | Improved fuel economy |

| Electric Motors | 350kW output | High-performance EVs |

Major manufacturers like Mercedes, Ferrari, and Honda use F1 research to develop their consumer hybrid and electric vehicles. The sport’s demanding conditions accelerate innovation timelines.

Hybrid Power And Environmental Impact

Hybrid power units have revolutionized F1 by combining performance with measurable environmental benefits. The current systems already show significant efficiency improvements over previous V8 engines.

The 2026 power units will achieve a near 50-50 split between electric and combustion power, compared to today’s 80-20 ratio. This dramatic shift reduces fuel consumption while maintaining similar total output.

F1 has reduced travel emissions by 25% since 2018, saving almost 20,000 tonnes of CO2 equivalent. The sport also transitions to renewable energy sources for powering race facilities and team operations.

Environmental Improvements:

- 35% better fuel efficiency than V8 engines

- Reduced noise pollution at race venues

- Lower overall carbon footprint per race weekend

The energy recovery systems capture kinetic energy during braking and store it in advanced battery systems. This recovered energy then assists acceleration, reducing the load on the internal combustion engine.

Major Manufacturers And The Competitive Edge

The hybrid era transformed Formula 1’s manufacturer landscape, with Mercedes establishing early dominance through superior energy recovery systems while competitors like Ferrari, Honda, Renault, Audi, and Ford pursued different technological approaches. This shift created intense competition as manufacturers invested heavily in hybrid technology development.

Mercedes’ Hybrid Power Dominance

Mercedes achieved unprecedented success when F1 transitioned to hybrid power units in 2014. The German manufacturer’s early investment in hybrid technology gave them a significant advantage over competitors.

Their power unit featured superior energy recovery systems. The MGU-H and MGU-K components worked together more efficiently than rival designs. This allowed Mercedes-powered cars to deploy more electrical energy per lap.

Key Mercedes advantages included:

- Better fuel efficiency during races

- More reliable power delivery

- Superior integration between combustion and electric power

- Advanced energy management systems

Mercedes won eight consecutive constructors’ championships from 2014 to 2021. Their power units powered teams like McLaren and Williams to multiple victories during this period.

The manufacturer’s dominance stemmed from understanding hybrid systems before regulations changed. They invested in the right technologies while competitors struggled with reliability issues.

Ferrari, Honda, Renault, Audi, And Ford Contributions

Ferrari developed their own hybrid approach focusing on combustion engine power. The Italian manufacturer created competitive power units but faced early reliability problems with their energy recovery systems.

Honda returned to F1 in 2015 with McLaren but struggled initially. Their “size zero” concept aimed for maximum aerodynamic efficiency but produced insufficient power. Honda later found success with Red Bull Racing from 2019 onwards.

Renault took a different path with their hybrid development. The French manufacturer prioritized driveability over peak power output. This approach helped their customer teams but limited championship contention.

Current manufacturer lineup includes:

- Mercedes: Supplies factory team and customer teams

- Ferrari: Powers Scuderia Ferrari and select customers

- Red Bull Powertrains: Took over Honda’s program

- Audi: Entering F1 in 2026 with hybrid technology

- Ford: Partnering with Red Bull for future development

Manufacturer Competition Under Hybrid Regulations

The 2026 power unit regulations aim to prevent single manufacturer dominance. F1 officials target convergence between power unit providers to create closer competition.

New regulations increase electrical power from 120kW to 350kW. This change requires manufacturers to develop more advanced battery and motor systems. The MGU-H system will be removed to reduce complexity and costs.

2026 regulation changes:

- Higher electrical power output

- Sustainable fuel requirements

- Simplified energy recovery systems

- Cost cap implementation

Manufacturers invested billions in hybrid technology development. The attraction of major automotive companies demonstrates F1’s relevance to road car technology.

Competition intensified as manufacturers recognized hybrid F1 as a testbed for consumer vehicle technology. Each manufacturer pursues different strategies for balancing combustion and electrical power delivery.

Frequently Asked Questions

The hybrid era has transformed Formula 1 through increased electrical power output, advanced energy recovery systems, and sustainable fuel integration. These changes have reshaped car performance, engineering approaches, and team strategies while supporting environmental goals.

What impact has the introduction of hybrid engines had on Formula 1 car performance?

Hybrid engines have dramatically increased the power available to F1 cars. The current systems generate 120kW of electrical power combined with traditional combustion engines.

The 2026 regulations will triple electrical power output to 350kW. This represents a massive jump in hybrid performance capability.

The additional electrical power provides instant torque delivery. This improves acceleration out of corners and enhances overall lap times.

Cars now recover energy through braking that was previously lost as heat. The 2026 rules will double energy recovery to 8.5 megajoules per lap.

How have hybrid power units influenced the design and engineering of F1 cars?

Hybrid technology has revolutionized F1 engineering by requiring new cooling systems for electrical components. Teams must manage heat from both engines and batteries.

Weight distribution changed significantly with battery placement. Engineers redesign chassis layouts to accommodate hybrid components while maintaining balance.

Energy management systems became crucial engineering elements. Teams develop complex software to optimize power deployment throughout races.

The 2026 cars will be 30 kilograms lighter despite more powerful hybrid systems. This requires advanced materials and engineering solutions.

What are the key differences between the hybrid power units in F1 and the previous generation of engines?

Previous F1 engines relied solely on naturally aspirated V8 or V10 combustion power. Modern units combine 1.6-liter turbocharged V6 engines with electrical systems.

The current hybrid systems include two energy recovery units. These capture energy from exhaust heat and braking that older engines wasted completely.

Fuel consumption dropped dramatically compared to previous generations. Current engines are the most efficient in the world while producing similar power levels.

Engine sound changed from high-pitched screams to deeper tones. The turbochargers and smaller displacement create different acoustic signatures.

How has the shift to hybrid technology affected fuel efficiency in F1 racing?

Modern F1 cars use significantly less fuel than previous generations. The hybrid systems recover energy that combustion-only engines lost as waste.

Current regulations limit fuel flow rates to 100 kilograms per hour. This forces teams to maximize efficiency rather than pure consumption.

The 2026 regulations introduce 100% sustainable fuels. These fuels contain no new fossil carbon and derive from waste sources.

Energy recovery systems contribute substantial power without burning additional fuel. This creates a more sustainable racing formula.

What strategies have teams adopted to optimize the performance of hybrid power units in F1?

Teams develop sophisticated energy deployment strategies for different track sections. Drivers can choose when to use electrical power for maximum advantage.

The 2026 rules will introduce manual override modes for overtaking. Following cars get extra electrical power when within one second of leaders.

Battery management becomes critical during races. Teams balance energy harvesting with deployment to maintain competitive pace.

Different energy harvesting strategies allow creative approaches. Drivers can vary their recovery methods based on track conditions and race situations.

How does the hybrid power unit technology align with the sustainability goals of Formula 1?

Formula 1’s hybrid transition addresses environmental concerns while maintaining racing excitement. The technology promotes cleaner automotive development.

The sustainable fuel initiative creates technology applicable to road cars. By 2030, 1.2 billion combustion vehicles could benefit from F1-developed fuels.

Manufacturer participation increased due to relevant technology development. Six manufacturers will compete from 2026, attracted by hybrid innovation opportunities.

The 50-50 energy split between combustion and electrical power supports automotive industry trends. This helps manufacturers develop technologies for consumer vehicles.