When drivers push their race cars to the limit on tracks around the world, an invisible force works behind the scenes to determine who wins and who loses. Aerodynamics became a serious factor in racing performance during the 1960s, transforming how engineers design cars and how drivers approach each corner and straightaway. The science of aerodynamics controls how air flows around a race car, directly affecting its speed, stability, and ability to maintain grip on the track.

Modern racing teams spend millions of dollars studying airflow patterns and testing aerodynamic components because small changes can mean the difference between victory and defeat. Teams invest significant resources into understanding and optimizing airflow around their vehicles to enhance downforce and improve cornering speeds. Every wing, spoiler, and body panel serves a specific purpose in managing the air that rushes over and under the car at high speeds.

From Formula 1’s sophisticated wing systems to NASCAR’s carefully shaped bodies, each racing discipline uses aerodynamics differently based on track conditions and competition rules. Active aerodynamics systems now allow real-time adjustments that help drivers adapt to changing race conditions and maximize their car’s performance throughout an entire race.

Key Takeaways

- Aerodynamics controls how air flows around race cars and directly impacts speed, stability, and grip on the track

- Modern teams use advanced technologies like wind tunnels and computer simulations to optimize every aerodynamic component

- Different racing series employ unique aerodynamic strategies based on their specific track types and competition regulations

Fundamentals of Aerodynamics in Racing

Racing aerodynamics involves three critical forces that directly impact vehicle performance: lift, drag, and downforce work together to determine how air interacts with a moving race car. Teams must balance these forces while managing airflow patterns to achieve maximum stability and speed on the track.

Understanding Aerodynamic Forces

Aerodynamics in racing involves the study of how air interacts with solid objects moving at high speeds. Three primary forces affect racing vehicles as they move through air.

Downforce pushes the car toward the track surface. This vertical force increases tire grip and allows drivers to take corners at higher speeds without losing control.

Drag creates resistance that opposes the car’s forward motion. While drag reduces top speed, it cannot be eliminated completely when generating downforce.

Lift works opposite to downforce by trying to raise the car off the track. Racing engineers design vehicles to minimize lift forces that could cause dangerous instability.

Air pressure differences around the vehicle create these forces. Higher pressure above the car and lower pressure below generates downforce through the same principles that create lift on airplane wings.

Balance of Downforce and Drag

Engineers strive to achieve optimal balance between downforce and drag for each specific track configuration. More downforce improves cornering speeds but increases drag on straightaways.

Teams adjust wing angles and aerodynamic components based on track characteristics. High-speed circuits require less downforce to maximize straight-line speed. Twisty tracks need more downforce for better cornering performance.

Aerodynamic efficiency measures how much downforce a car generates relative to its drag penalty. The most efficient designs produce maximum downforce with minimal drag increase.

Different racing series have varying requirements. Formula 1 cars generate extreme downforce levels while sports cars balance aerodynamic performance with other design priorities.

Airflow and Vehicle Stability

Airflow management around race cars directly affects vehicle stability and handling characteristics. Smooth airflow reduces turbulence and maintains consistent aerodynamic forces.

Fluid dynamics principles govern how air moves around the vehicle body. Engineers use computational fluid dynamics and wind tunnel testing to optimize airflow patterns.

Air moving under the car creates ground effect when channeled properly. This low-pressure area beneath the vehicle generates significant downforce without adding drag from wings.

Vehicle stability depends on maintaining consistent airflow at different speeds and track conditions. Sudden airflow changes can cause unpredictable handling that makes cars difficult to drive at racing speeds.

Key Aerodynamic Components in Race Cars

Race cars use specialized parts to control airflow and maximize performance on track. Wings create downforce to press cars against the ground, while diffusers and underbody designs manage air underneath the vehicle for stability and speed.

Function of Front and Rear Wings

The front wing serves as the first point of contact with incoming air. It directs airflow around the car while generating downforce to improve front-end grip.

Front wings feature multiple elements and adjustable flaps. Teams can change the wing angle to balance downforce and drag for different track conditions.

Key front wing functions:

- Generate front downforce

- Direct airflow to rear components

- Balance aerodynamic package

- Reduce turbulence around front wheels

Rear wings work differently than front wings. They create the majority of a car’s downforce by using the aerodynamic principles that govern racing performance.

The rear wing catches clean air flowing over the car. This positioning allows it to generate maximum downforce without interference from other components.

Teams adjust rear wing angles based on track requirements. High-downforce tracks need steeper angles, while fast circuits require flatter settings to reduce drag.

Role of Diffusers and Underbody Design

Diffusers accelerate air flowing underneath the car. This creates low pressure that pulls the vehicle toward the track surface through ground effect.

The diffuser starts narrow at the front and widens toward the rear. This shape forces air to speed up as it exits, creating a suction effect underneath the car.

Diffuser benefits:

- Generate ground effect downforce

- Reduce drag compared to wings

- Improve stability at high speeds

- Work efficiently in dirty air

Underbody design complements the diffuser system. Teams create smooth, sealed floors that prevent air from entering underneath the car.

Ground effect provides significant performance advantages over traditional wing-based downforce. It generates grip with less drag penalty than external wings.

Modern race cars use sophisticated underbody tunnels. These channels guide air toward the diffuser for maximum ground effect generation.

Importance of Bodywork and Bargeboards

Bodywork shapes determine how air flows around the entire vehicle. Smooth, curved surfaces reduce drag while directing airflow to critical areas.

Teams design bodywork to minimize turbulence around wheels and suspension components. Clean air improves the effectiveness of downstream aerodynamic elements.

Bargeboards are vertical fins located ahead of the side pods. They control airflow around the car’s midsection and prevent turbulent air from reaching the rear wing.

Bargeboard functions:

- Direct airflow around side pods

- Reduce wheel wake turbulence

- Improve rear wing efficiency

- Generate small amounts of downforce

Side pod design affects cooling and aerodynamics equally. Engineers balance airflow requirements for radiators with external aerodynamic performance.

The nose cone and cockpit area create significant drag. Teams use careful shaping to minimize this effect while maintaining driver safety requirements.

Spoilers and Active Aerodynamics

Spoilers differ from wings in their basic function. They disrupt airflow to reduce lift rather than actively generating downforce like traditional wings.

Most spoilers work by breaking up smooth airflow over curved surfaces. This prevents the low pressure that would otherwise create unwanted lift forces.

Spoiler applications:

- Reduce rear lift on sports cars

- Improve high-speed stability

- Simple alternative to complex wings

- Cost-effective aerodynamic solution

Active aerodynamics systems adjust components automatically during racing. These systems optimize the aerodynamic package for changing track conditions.

Active rear wings change angle based on speed and braking. They provide maximum downforce in corners but reduce drag on straight sections.

Some racing series allow moveable aerodynamic components. Drivers can adjust wing angles from the cockpit to suit different parts of the track.

Active systems require sophisticated control software. Sensors monitor vehicle speed, steering input, and braking to determine optimal aerodynamic settings.

Aerodynamics and Race Car Performance

Aerodynamics plays a crucial role in race car performance, directly affecting how fast cars can go and how well they handle on the track. The science of airflow around vehicles determines three key performance areas: maximum speed capabilities, cornering effectiveness, and high-speed stability.

Influence on Speed and Acceleration

Drag reduction represents the primary aerodynamic factor that determines a race car’s top speed potential. Engineers design sleek body shapes to minimize air resistance and allow cars to cut through air more efficiently.

Key speed factors include:

- Body shape smoothness

- Front and rear spoiler angles

- Air intake positioning

- Underbody airflow management

Vehicle design teams focus on creating streamlined profiles that reduce turbulence. This allows engines to use more power for forward motion instead of fighting air resistance.

Race cars with better aerodynamic efficiency can reach higher speeds on straightaways. They also accelerate faster out of corners because less engine power gets wasted overcoming drag forces.

Modern motorsports teams use wind tunnels to test different body configurations. Small changes in aerodynamic design can improve lap times by several seconds over a full race distance.

Impact on Cornering Grip and Handling

Downforce generation significantly improves cornering performance by pushing cars down onto the track surface. This increased contact pressure allows tires to maintain better grip during high-speed turns.

Downforce benefits:

- Increased tire contact pressure – More force pressing tires to track

- Higher corner speeds – Cars can turn faster without losing control

- Better handling response – Steering inputs become more predictable

Aerodynamic components like wings and diffusers create this downward force. Front wings help with steering precision while rear wings provide stability during cornering.

The trade-off involves balancing downforce with drag. More downforce improves grip but reduces straight-line speed. Teams adjust these settings based on track characteristics and racing conditions.

Stability at High Speeds

High-speed stability depends on proper aerodynamic balance between the front and rear of the vehicle. Uneven airflow can cause dangerous handling problems at racing speeds.

Stability elements:

- Front-to-rear downforce distribution

- Side force management in crosswinds

- Aerodynamic center positioning

Race cars become unstable when aerodynamic forces shift dramatically. Sudden lift can cause cars to lose contact with the track surface, leading to crashes.

Engineers carefully design body shapes to maintain consistent airflow patterns. This prevents sudden changes in handling characteristics as speeds increase throughout a race.

Proper aerodynamic stability allows drivers to maintain control during close racing situations. Cars remain predictable even when following other vehicles through turbulent air.

Technologies and Methods for Aerodynamic Optimization

Racing teams use three main technologies to improve their cars’ aerodynamic performance. These methods work together to reduce drag and increase downforce for better speed and handling.

Computational Fluid Dynamics (CFD)

CFD uses computer simulations to predict how air flows around racing cars. Teams can test different designs quickly without building physical models.

Racing aerodynamics research shows that Formula 1 teams like Red Bull Racing use CFD to improve their cars. They analyze airflow around side boxes and other parts to find the best designs.

Key CFD Benefits:

- Fast testing of multiple designs

- Lower costs than physical testing

- Detailed airflow visualization

- Easy design changes

CFD helps engineers understand complex airflow patterns. They can see where air creates drag or reduces downforce before building real parts.

The technology lets teams test hundreds of design options in days. This speed gives them more time to find the perfect setup for each race track.

Wind Tunnel Testing

Wind tunnel experiments validate CFD results using physical models. Teams typically test 60% scale models to measure real airflow effects on their cars.

The Mercedes-AMG F1 team uses wind tunnels to test their chassis diffusers. These tests help them maximize ground effects for better cornering stability.

Wind Tunnel Advantages:

- Real airflow measurement

- Accurate force readings

- CFD validation

- Physical testing confirmation

Wind tunnels reveal problems that computer simulations might miss. Real air behaves differently than computer models sometimes predict.

Teams measure exact downforce and drag numbers from these tests. They adjust wing angles and body shapes based on the data they collect.

Modern racing development combines both CFD and wind tunnel work. This approach ensures the most accurate aerodynamic designs possible.

AI and Data-Driven Design

Artificial intelligence now helps optimize racing car aerodynamics faster than traditional methods. AI-driven aerodynamic optimization uses data to find better designs automatically.

Machine learning analyzes thousands of aerodynamic configurations quickly. It finds patterns that human engineers might miss in complex airflow data.

AI Applications:

- Automatic design optimization

- Pattern recognition in airflow

- Predictive performance modeling

- Real-time adjustment systems

Machine learning in aerodynamics reduces the need for expensive CFD simulations. AI can predict how design changes affect performance before running full tests.

Future racing cars may use AI for real-time aerodynamic adjustments. These systems could change wing angles automatically based on track conditions and racing situations.

Teams are exploring adaptive aerodynamic structures that respond to different racing environments. This technology could give cars the perfect setup for any track condition.

Aerodynamic Strategies in Different Racing Disciplines

Racing teams use different air flow methods based on their sport’s rules and track conditions. Formula 1 cars focus on downforce and drag reduction, while NASCAR teams work with restricted parts and oval track demands.

Formula 1 Innovations

Formula 1 uses the most advanced air flow technology in racing. Teams spend millions on wind tunnels and computer models to find tiny speed gains.

Active Aerodynamics

Modern F1 cars have adjustable aerodynamics like DRS wings. The Drag Reduction System opens the rear wing on straights. This cuts air resistance by up to 10%.

Ground Effect Technology

The 2022 rule changes brought back ground effect. Cars now create downforce through floor design instead of complex wings. This lets cars follow each other more closely.

Wing Design Evolution

F1 wings have hundreds of small parts called elements. Each piece directs air flow in specific ways. Front wings have up to five separate sections. Rear wings adjust for each track’s needs.

Teams test new parts every race weekend. They use sensors to measure air pressure at over 100 points on the car.

NASCAR Aerodynamic Approaches

NASCAR has strict rules about car shapes and wing sizes. Teams must work within these limits to find speed advantages.

Restricted Development

NASCAR controls most aerodynamic parts. All cars use the same basic body shape. Teams can only adjust small details like spoiler angle and front splitter height.

Oval Track Focus

NASCAR tracks are mostly ovals with banking. Cars need less downforce than F1 but require stable air flow in traffic. Side force becomes important in turns.

Drafting Strategy

Cars run close together to reduce drag. The lead car cuts through air while following cars get a speed boost. This technique can add 5-10 mph on superspeedways.

Body Panel Optimization

Teams focus on small details like door seams and window angles. Even tiny changes can affect lap times by several tenths of a second.

Adaptation Across Motorsports

Aerodynamic strategies differ widely across racing disciplines based on track types and technical rules. Each sport has unique challenges that shape car design.

Rally Racing

Rally cars need different setups for gravel, snow, and tarmac stages. Wings must work at various speeds and angles. Most rally cars use simple wing designs that resist damage from debris.

IndyCar Racing

IndyCar uses spec aerodynamic packages for different track types. Road course setups maximize downforce. Oval packages reduce drag and increase straight-line speed.

Sports Car Racing

Endurance racing balances speed with fuel efficiency. Modern racing prioritizes energy efficiency alongside performance. Teams adjust aerodynamics during long races as fuel loads change.

Motorcycle Racing

MotoGP bikes use wings and fairings to control wheelies and improve stability. Riders’ body positions become part of the aerodynamic package. Small changes in riding posture can affect lap times.

The Relationship Between Aerodynamics and Driver Performance

Good aerodynamic design directly impacts how drivers handle their cars and make strategic decisions during races. Aerodynamics quietly governs every aspect of racing performance, affecting both vehicle control and tactical choices on the track.

Enhancing Driver Control and Safety

Aerodynamic efficiency creates predictable handling characteristics that drivers can rely on. When air flows smoothly over a car’s body, it generates consistent downforce that keeps the vehicle stable.

This stability allows drivers to push harder through corners. They can brake later and accelerate earlier because they trust their car’s grip levels.

Key Control Benefits:

- Better steering response at high speeds

- Reduced body roll in corners

- More predictable braking performance

- Enhanced stability during overtaking moves

Poor aerodynamics creates the opposite effect. Cars with aerodynamic problems become difficult to control as speeds increase.

Drivers must adapt their technique when aerodynamic balance shifts. A car that loses rear downforce becomes oversteery and snappy. Too much front downforce makes the car understeer and feel sluggish.

Aerodynamics plays a crucial role in maintaining grip on the track, which directly translates to driver confidence. When drivers trust their cars, they can focus on racing instead of fighting handling issues.

Aerodynamics in Race Strategy

Teams use aerodynamic setups as strategic tools throughout race weekends. Different wing angles and configurations suit different track conditions and race situations.

Strategic Aerodynamic Choices:

- Low downforce: Higher top speeds for tracks with long straights

- High downforce: Better cornering for twisty circuits

- Medium downforce: Balanced approach for mixed track layouts

Weather conditions change aerodynamic effectiveness. Rain reduces tire grip, making downforce more valuable for maintaining control. Hot conditions affect air density and cooling requirements.

Tire strategy connects directly to aerodynamic choices. Cars with more downforce put extra stress on tires but gain cornering speed. Teams must balance this trade-off based on tire compound and race distance.

Fuel load also impacts aerodynamic balance. Heavier cars at race start behave differently than light cars near the end. Engineers create cars that perform at their best under varying conditions by accounting for these weight changes.

Draft strategy depends on aerodynamic drag levels. Cars with less drag can follow closer to competitors and use slipstream effects more effectively during overtaking attempts.

Frequently Asked Questions

Racing teams face complex challenges when balancing downforce generation with drag reduction while working within strict regulatory frameworks. Modern computational tools and decades of aerodynamic innovation have transformed how engineers approach vehicle design and performance optimization.

How do aerodynamics affect the handling of a race car at high speeds?

Aerodynamics creates downforce that pushes race cars onto the track surface, increasing tire grip during high-speed cornering. This vertical force allows drivers to take turns faster without losing control.

The car’s aerodynamic balance between front and rear downforce determines how it handles through different corner types. Too much front downforce makes the car understeer, while excessive rear downforce causes oversteer.

Air flowing over the car also creates drag that resists forward motion. Engineers must find the right balance between generating enough downforce for grip while minimizing drag for straight-line speed.

What are the most crucial aerodynamic elements in a Formula 1 car?

The front wing directs airflow around the car and generates initial downforce while managing turbulent air from the front tires. It serves as the starting point for all airflow management on the vehicle.

The rear wing provides the most visible downforce generation and includes the DRS system for reducing drag on straights. The diffuser underneath the car creates significant downforce by accelerating air flow beneath the vehicle.

Bargeboards guide airflow around the sidepods and help manage turbulence from the front wheels. The floor and underfloor sections work together to create ground effect that pulls the car toward the track surface.

How is computational fluid dynamics (CFD) used in the development of racing vehicles?

CFD simulations allow engineers to analyze airflow patterns around virtual car models before building physical prototypes. Teams can test thousands of design variations digitally to identify the most promising aerodynamic configurations.

The software calculates forces like downforce and drag across different car components. Engineers use these results to optimize wing angles, body shapes, and other aerodynamic elements.

CFD work is now limited by regulations in Formula 1 to control development costs and level the playing field between teams. Wind tunnel testing validates CFD results with physical models.

Can you explain the relationship between downforce and drag in race car design?

Downforce and drag are directly linked because both result from air flowing over the car’s surfaces. Generating more downforce typically increases drag, creating a fundamental trade-off in race car design.

Teams adjust this balance based on track characteristics. High-downforce setups work best on twisty circuits where cornering speed matters most.

Low-drag configurations suit tracks with long straights where top speed is critical. Engineers constantly seek designs that maximize downforce while minimizing drag penalties.

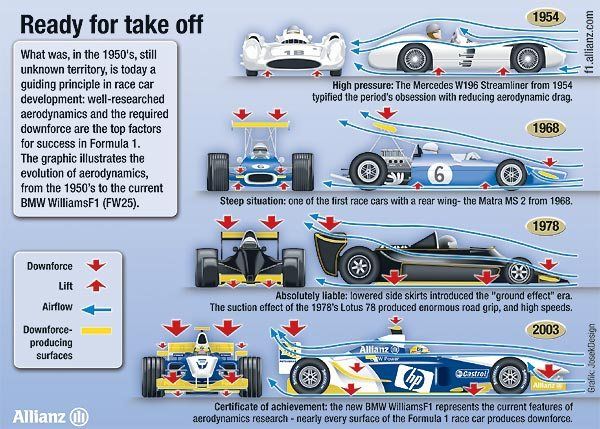

What advancements in aerodynamics have been significant in the history of racing?

Aerodynamics became a serious factor in racing during the 1960s, moving beyond simple streamlined shapes to active downforce generation. The introduction of wings marked the beginning of modern aerodynamic development.

Ground effect technology in the 1970s created massive downforce by sealing the car’s underside to the track. Active suspension systems briefly allowed real-time aerodynamic adjustments before being banned.

Modern CFD and wind tunnel facilities have revolutionized development speed and precision. Teams can now optimize designs with accuracy that was impossible in earlier decades.

How do regulations impact the aerodynamic design of competitive racing cars?

Technical regulations restrict aerodynamic development to ensure fair competition and control costs between teams. Rules limit wing dimensions, floor designs, and development resources like wind tunnel time.

The 2022 Formula 1 regulation changes focused on reducing aerodynamic wake to improve overtaking opportunities. These rules forced teams to redesign their entire aerodynamic packages.

Regulations also address safety concerns by preventing cars from generating too much lift or becoming airborne. Rules evolve constantly as governing bodies respond to new technologies and competitive imbalances.