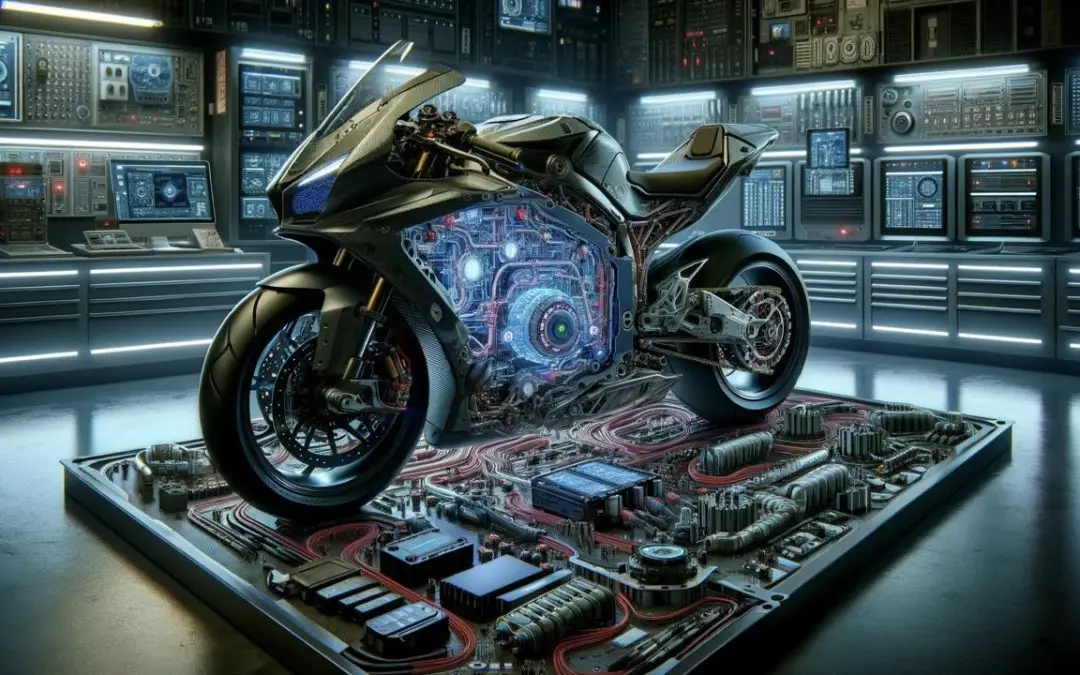

MotoGP has transformed from a sport where raw throttle control separated legends from also-rans into a high-tech arena dominated by sophisticated computer systems. Electronic aids like traction control, anti-wheelie systems, and engine braking management have fundamentally changed how riders approach corners and manage the immense power of modern Grand Prix motorcycles. Electronics became prevalent in motorcycle Grand Prix racing at the dawn of the MotoGP formula in 2002, marking the beginning of a technological revolution.

The shift from mechanical mastery to digital precision has created both controversy and opportunity in the paddock. While some fans argue that electronic rider aids have removed spectacle from the series, these systems have enabled riders to push performance boundaries while maintaining safety standards. Modern MotoGP bikes now feature 26 sensors that provide information to manage everything from wheelspin to tire wear.

This evolution extends far beyond simple traction control systems. The integration of electronics with aerodynamics, advanced materials, and suspension technology has created a new paradigm where understanding data becomes as crucial as physical skill. Riders must now master both the art of speed and the science of electronic management to compete at the highest level.

Key Takeaways

- Electronic aids transformed MotoGP from a sport dominated by throttle control mastery to one requiring digital precision and data understanding

- Modern MotoGP bikes use 26 sensors and sophisticated computer systems to manage traction, wheelies, and power delivery for optimal performance

- The integration of electronics with aerodynamics and advanced materials has created safer racing while pushing the boundaries of motorcycle technology

Foundations of Electronic Aids in MotoGP

Modern MotoGP relies on three core electronic systems that transformed motorcycle racing from a purely mechanical sport into a high-tech battleground. These systems manage engine power, collect performance data, and provide riders with unprecedented control over their machines.

Defining Electronic Aids in Motorcycle Racing

Electronic aids are computer-controlled systems that help riders manage their motorcycles during races. These systems work automatically to improve safety and performance.

Traction control prevents rear wheels from spinning when riders apply too much throttle. The system cuts engine power when sensors detect wheel slip.

Launch control helps riders get perfect starts from the grid. It manages engine power and wheel spin during the critical first seconds of a race.

Anti-wheelie systems keep front wheels on the ground during hard acceleration. Sensors detect when the bike tilts too far forward and reduce power instantly.

Engine braking control smooths out deceleration when riders close the throttle. This prevents the rear wheel from locking up during corner entry.

Electronic rider aids transformed MotoGP by giving all riders access to consistent performance. Before these systems, only riders with exceptional throttle control could extract maximum speed from their machines.

The systems use dozens of sensors throughout motogp bikes. These sensors monitor wheel speed, lean angle, throttle position, and engine temperature hundreds of times per second.

The Role of Engine Control Units

The Engine Control Unit (ECU) acts as the brain of every MotoGP motorcycle. This computer processes sensor data and makes split-second decisions about engine performance.

MotoGP uses a spec ECU system since 2016. All teams must use the same basic computer hardware from Magneti Marelli. This levels the playing field between factory teams and smaller operations.

The ECU controls several critical functions:

- Fuel injection timing for optimal power delivery

- Ignition timing across different RPM ranges

- Throttle response through electronic throttle bodies

- Power delivery maps for different track conditions

Teams can still program their own software within strict rules. Engineers create custom maps for each track and weather condition.

The ECU receives input from over 20 sensors on modern motogp bikes. It processes this data in real-time to adjust engine behavior thousands of times per lap.

Throttle-by-wire technology replaced traditional throttle cables in the early 2000s. This allows the ECU to modify rider inputs before they reach the engine.

Telemetry Systems and Data Analytics

Telemetry systems transmit real-time data from racing motorcycles to pit crews during practice and races. This technology revolutionized how teams understand bike performance.

Modern MotoGP bikes send over 300 channels of data back to the pits. This includes engine temperatures, suspension movement, brake pressure, and rider inputs.

GPS systems track exact bike position and speed at every point on the circuit. Teams use this data to identify where riders gain or lose time compared to competitors.

Data analytics help engineers make setup changes between sessions. They can see exactly how modifications affect lap times and rider confidence.

Key telemetry measurements include:

- Lean angles up to 64 degrees in corners

- Braking forces exceeding 1.5G deceleration

- Acceleration data from multiple sensors

- Tire temperature across different zones

Teams employ data analysts who work alongside traditional mechanics. These specialists interpret thousands of data points to find performance advantages.

Telemetry provides understanding that’s bigger than engine controls according to technical experts. The data helps teams optimize everything from suspension settings to aerodynamic packages.

Historical Development: From Mechanical to Digital

MotoGP’s transformation from mechanical systems to digital technology began in 2002 with the sport’s official launch. Electronics became prevalent in motorcycle Grand Prix racing at the dawn of the MotoGP formula, marking a shift from basic mechanical controls to sophisticated computer-managed systems.

Early Electronic Systems in MotoGP

The first electronic systems in MotoGP were basic compared to today’s standards. Teams used simple engine management units to control fuel injection and ignition timing.

Early traction control systems worked by cutting ignition to individual cylinders when wheel spin was detected. These systems were crude and often jerky in their operation.

Basic Electronic Components (2002-2005):

- Fuel injection mapping

- Ignition timing control

- Basic traction control

- Simple data logging

The introduction of throttle by wire systems replaced mechanical cables with electrical connections. This change allowed engineers to program how engines responded to rider inputs.

Manufacturers developed their own electronic systems during this period. Each brand used different approaches to manage power delivery and bike behavior.

Transition from Two-Stroke to Four-Stroke Engines

The 2002 season marked the end of 500cc two-stroke engines in the premier class. Four-stroke 990cc engines became the new standard for MotoGP competition.

Two-stroke engines had simpler power delivery that riders could predict easily. Four-stroke engines produced more complex power curves that required electronic management.

Key Differences:

| Two-Stroke | Four-Stroke |

|---|---|

| Simple power delivery | Complex power curves |

| Light weight | Heavier construction |

| Mechanical controls | Electronic management needed |

| Predictable behavior | Required rider aids |

The change to four-stroke engines made electronic aids necessary rather than optional. These engines produced more torque and required better control systems to manage power delivery.

By 2003, no two-stroke bikes remained on the MotoGP grid. All manufacturers had switched to four-stroke technology with electronic management systems.

Advances in Throttle Response and Engine Performance

Ride-by-wire throttle systems eliminated mechanical cables and replaced them with electrical wires. This technology allowed precise control over engine response characteristics.

Engineers could program different throttle maps for various track conditions. Riders gained the ability to adjust how aggressively engines responded to throttle inputs.

Throttle Response Improvements:

- Programmable response curves

- Multiple map selections

- Real-time adjustments

- Integration with traction control

Engine performance increased dramatically with electronic management. Four-stroke engines produced over 240 horsepower while maintaining better fuel efficiency than their two-stroke predecessors.

Electronic systems allowed riders to push bikes to their limits with greater precision and control. Lap times dropped consistently as electronic aids became more sophisticated.

The combination of powerful four-stroke engines and advanced electronics created the foundation for modern MotoGP technology. These systems enabled the complex rider aids that define today’s racing motorcycles.

Modern Electronic Rider Aids

Today’s MotoGP bikes use advanced electronic systems that control wheel spin, prevent dangerous wheelies, and manage braking forces with precision. These electronic rider aids ensure optimal bike performance while allowing riders to push machines producing over 270 horsepower to their absolute limits.

Traction Control Evolution and Integration

Modern traction control systems rely on wheel speed sensors to detect when the rear wheel spins faster than the front wheel. When the rear wheel exceeds front wheel speed by about 12%, the system activates instantly.

The Electronic Control Unit (ECU) uses multiple correction methods. It can cut throttle input through ride-by-wire technology or adjust ignition timing on individual cylinders.

Key Integration Factors:

- Lean angle sensors

- Gear position data

- Suspension position

- Track surface conditions

The system calculates these variables in milliseconds. When a rider accelerates hard through a 60-degree lean angle, sensors detect excessive rear wheel slip immediately.

Traction control has evolved significantly since the 990cc era when electronic aids were less intrusive. Modern systems allow controlled rear wheel slip while maintaining stability and preserving tire life.

Anti-Wheelie and Launch Systems

Anti-wheelie control prevents the front wheel from lifting during hard acceleration. Unlike traction control, this system focuses purely on performance optimization rather than safety.

The system monitors front and rear wheel speed differences during acceleration. When the front wheel slows while the engine accelerates, sensors detect potential wheelie conditions.

Detection Methods:

- Front fork suspension sensors

- Inertial measurement platforms

- Wheel speed comparisons

- Throttle position data

Suspension sensors on the front fork indicate when the wheel leaves the ground. The system responds by restricting throttle opening or cutting ignition to specific cylinders.

Launch control systems activate during race starts. They limit engine power delivery to prevent excessive wheelies while maximizing acceleration off the starting grid.

These systems ensure maximum acceleration whether at the start line or when taking a turn. Modern anti-wheelie technology has become more basic due to Dorna’s restrictions on system upgrades.

Anti-Lock Braking System (ABS) and ESC

MotoGP bikes use sophisticated braking systems that prevent wheel lockup during extreme deceleration. These systems work differently from road bike ABS due to the extreme lean angles and speeds involved.

Electronic Stability Control (ESC) manages multiple aspects of bike behavior simultaneously. It coordinates braking, traction control, and throttle response based on lean angle and track conditions.

ABS Integration Features:

- Cornering-specific algorithms

- Lean angle compensation

- Front and rear brake coordination

- Track surface adaptation

The systems account for the physics of motorcycle racing at extreme lean angles. Even with advanced cornering ABS and traction control, there’s a limit to how much lean angle and speed a bike can handle.

Modern electronic aids work together as integrated systems rather than independent components. They share data continuously to provide seamless rider assistance without compromising the competitive nature of MotoGP racing.

Aerodynamics and Electronic Synergy

Modern MotoGP bikes combine advanced aerodynamic features with sophisticated electronic systems to maximize performance. Winglets and computational fluid dynamics work together with electronic aids to create faster, more stable machines that have transformed racing strategies.

Aerodynamic Design and Winglets

Aerodynamic design in modern MotoGP relies heavily on electronic data to optimize performance. Engineers use electronic sensors to measure air pressure, speed, and bike stability in real time.

Winglets became crucial for stability at extreme speeds and now appear on production motorcycles. These small fins help control airflow and reduce wheelies during acceleration.

Electronic systems monitor how winglets affect bike behavior. Sensors track front wheel lift and adjust engine power accordingly. This data helps teams understand when aerodynamic downforce works best.

Key aerodynamic elements include:

- Front winglets for downforce

- Fairing shapes for reduced drag

- Rear sections for airflow management

- Side panels for heat dissipation

Teams adjust winglet angles based on electronic feedback from practice sessions. This creates better grip and allows riders to brake later into corners.

Role of Computational Fluid Dynamics (CFD)

CFD technology helps teams design aerodynamic packages before building physical parts. Engineers run thousands of simulations to test different wing shapes and positions.

Electronic sensors validate CFD predictions during track testing. Teams compare computer models with real-world data from multiple sensors around the bike.

Modern CFD programs work with electronic systems to predict how aerodynamic changes affect handling. This saves time and money compared to building multiple prototype parts.

CFD applications in MotoGP:

- Wing design optimization

- Fairing shape development

- Heat management solutions

- Drag reduction analysis

Engineers use CFD data to program electronic systems for different track conditions. Aerodynamic loads change how traction control and anti-wheelie systems must respond.

Impact on Race Strategy and Motorcycle Technology

Aerodynamic improvements allow riders to maintain higher speeds on straights and through corners. Electronic systems adapt to these speed increases automatically.

Race strategy now considers aerodynamic performance at different tracks. Fast circuits favor bikes with low drag, while twisty tracks need maximum downforce for cornering.

Electronic data helps teams choose the right aerodynamic setup for each race weekend. Sensors measure tire temperatures, lap times, and fuel consumption with different wing configurations.

Strategic considerations include:

- Track-specific wing setups

- Weather condition adaptations

- Tire wear optimization

- Fuel consumption management

MotoGP technology influences aftermarket motorcycle parts as aerodynamic innovations move to street bikes. Electronic systems help riders benefit from these racing-derived features safely.

Materials, Chassis, and Suspension Integration

MotoGP’s electronic evolution requires specially designed materials and structures to house complex systems. Carbon fiber construction reduces weight while titanium components handle extreme stress, and advanced suspension technologies integrate electronic damping for precise control.

Lightweight Materials and Carbon Fiber Advances

Carbon fiber dominates MotoGP construction due to its strength-to-weight ratio. Teams use different carbon fiber weaves for specific applications across the motorcycle frame.

The material allows engineers to embed wiring harnesses directly into structural components. This integration eliminates separate mounting points for electronic systems.

Key Carbon Fiber Applications:

- Fuel tanks with integrated sensors

- Fairings housing electronic control units

- Swingarms with built-in data cables

- Subframes supporting battery systems

Titanium fasteners secure electronic components while reducing overall weight. The metal resists vibration loosening better than steel alternatives.

Lightweight materials like magnesium housings protect sensitive electronics from track debris. These materials also dissipate heat generated by high-performance processors.

Chassis Design for Electronics Compatibility

Modern MotoGP chassis integrate electronic systems from the initial design phase. Engineers create dedicated spaces for control units within the frame structure.

The main ECU typically mounts near the bike’s center of gravity. This placement reduces the impact of electronics on handling characteristics.

Electronic Integration Points:

| Component | Location | Purpose |

|---|---|---|

| Main ECU | Under fuel tank | Central processing |

| IMU sensor | Frame centerline | Motion detection |

| Data logger | Tail section | Information storage |

| Wiring harness | Frame tubes | Signal transmission |

Chassis design accommodates multiple sensors throughout the frame. Strain gauges measure chassis flex while temperature sensors monitor component heat.

Manufacturers use different approaches to wire routing. Some teams run cables through hollow frame sections while others use external protective channels.

Suspension Systems and Electronic Damping

Electronic damping systems adjust compression and rebound settings in real-time. These systems respond to track conditions within milliseconds of detection.

Suspension systems receive input from multiple sensors including wheel speed and lean angle. The data helps optimize damping for each corner.

Electronic Damping Features:

- Compression control: Adjusts fork dive under braking

- Rebound tuning: Manages wheel contact after bumps

- Preload variation: Changes ride height dynamically

- Anti-dive systems: Reduces front end movement

Front and rear suspension units connect to the main electronic network. They receive commands through dedicated communication protocols.

The integration allows suspension to work with traction control and wheelie control systems. This coordination improves overall bike stability during acceleration and braking phases.

Influence on Rider Safety and Environmental Impact

Electronic aids have transformed MotoGP through mandatory airbag systems in riders’ suits and fuel-saving technologies. These systems reduce crash injuries while cutting emissions through precise engine management and alternative fuel development.

Integration of Airbag Suits and Safety Gear

Advanced airbag systems deploy in milliseconds during crashes to protect riders’ spine, chest, and shoulders. These electronic safety systems use accelerometers and gyroscopes to detect impact patterns.

The suits connect wirelessly to bike sensors. They monitor lean angles, speed changes, and crash signatures in real-time.

Modern airbag suits inflate within 15 milliseconds of detection. This speed prevents serious injuries during high-speed crashes at over 200 mph.

Electronic integration extends beyond airbags. Helmet communication systems alert medical teams instantly when crashes occur.

Bike designs now incorporate improved crash resistance through electronic energy absorption features. These systems work with rider gear to create comprehensive protection networks.

Electronics’ Role in Fuel Efficiency

Electronic fuel injection systems optimize combustion timing thousands of times per second. They adjust fuel delivery based on throttle position, engine temperature, and track conditions.

Traction control prevents wheel spin that wastes fuel. The system reduces unnecessary power delivery during acceleration phases.

Key fuel-saving electronics:

- Engine mapping systems

- Throttle-by-wire controls

- Real-time combustion monitoring

- Automatic gear shift optimization

Electronic systems monitor fuel consumption lap by lap. Teams adjust engine settings to maximize efficiency during long races.

Advanced sensors measure air density and track temperature. The electronics compensate by adjusting fuel mixtures automatically.

These technologies reduce fuel consumption by up to 12% compared to mechanical systems. The savings help teams meet strict fuel allocation limits.

Reducing the Carbon Footprint

MotoGP will use 100% non-fossil fuel sources starting in 2027. Electronic systems must adapt to manage these alternative fuels effectively.

Synthetic fuels require different combustion timing than gasoline. Electronic engine management systems adjust automatically to optimize performance.

Environmental benefits of electronic aids:

- Reduced emissions through precise fuel control

- Lower fuel consumption rates

- Support for sustainable fuel development

- Decreased waste from mechanical parts

Electronic systems help manufacturers develop cleaner technologies. These innovations transfer to consumer motorcycles within three to five years.

Battery management systems in hybrid prototypes extend electric-only operation. They coordinate with combustion engines to minimize emissions during testing phases.

The carbon footprint drops significantly through electronic optimization. Teams report 18% fewer emissions per race kilometer with modern electronic systems.

Frequently Asked Questions

Electronic aids in MotoGP have transformed how bikes handle power delivery and maintain stability. These systems now control everything from wheel spin to suspension adjustments in real-time.

What advancements in electronic aids have significantly impacted MotoGP racing performance?

Electronics became widespread in MotoGP racing in 2002 with the introduction of the new formula. Throttle-by-wire technology led to major increases in electronic systems.

Traction control systems prevent rear wheel spin by monitoring wheel speed sensors. When the rear wheel turns about 12% faster than the front wheel, the system reduces engine power.

Anti-wheelie control keeps the front wheel on the ground during acceleration. The system uses suspension sensors and wheel speed data to detect when the front wheel lifts.

Engine braking management helps riders control deceleration into corners. This system manages how much engine braking force gets applied when riders close the throttle.

How have electronic rider assists evolved in MotoGP over the years?

Early electronic aids in the 1990s were basic compared to modern systems. MotoGP encouraged widespread use of throttle by wire technology, which enabled more advanced rider aids.

The 990cc era saw rapid development of electronic systems. Manufacturers developed increasingly complex traction control and anti-wheelie systems.

Dorna introduced unified ECU software to limit electronic development costs. This standardization made the systems more basic but kept competition fair across all teams.

Modern MotoGP bikes use inertial measurement platforms that track lean angle and acceleration. These sensors provide much more detailed data than early wheel speed sensors alone.

What role do electronic controls play in MotoGP bike stability and handling?

Electronic systems like traction control and anti-wheelie ensure optimal bike performance. These aids allow riders to push their machines to the absolute limit safely.

Traction control maintains rear wheel grip during cornering and acceleration. The system prevents dangerous rear wheel slides that could cause crashes.

Lean angle sensors help electronic systems adjust their response based on cornering position. A bike leaning at 60 degrees needs different electronic intervention than one upright.

Electronic suspension systems adjust damping and spring rates instantly. These systems respond to track conditions and riding style in real-time.

How has the introduction of traction control changed the racing strategies in MotoGP?

Electronic rider aids have removed some spectacle from MotoGP racing. The systems control wheelspin and manage tire wear automatically.

Traction control allows riders to use maximum throttle earlier in corners. This changes how riders approach corner exits and straight-line acceleration.

Race strategies now focus more on corner speed than throttle control skills. MotoGP has become a series where carrying corner speed is most important.

Electronic aids reduce the skill gap between riders in some areas. Pure throttle control ability matters less than it did before electronic systems.

What safety improvements have electronic aids facilitated in professional motorcycle racing?

Controlling around 270 horsepower on one wheel would be impossible without electronics. These systems prevent many crashes that pure rider skill alone cannot avoid.

Traction control prevents dangerous highside crashes from rear wheel spin. These crashes happen when the rear wheel suddenly regains grip after sliding.

Anti-wheelie systems reduce the risk of backwards crashes during acceleration. Uncontrolled wheelies can cause riders to flip over backwards.

Electronic systems react much faster than human reflexes can. The systems make corrections in fractions of a second that prevent crash situations.

Can you explain the impact of electronic suspension systems on MotoGP competition?

Electronic suspension adjusts damping rates automatically during races. These systems respond to braking, acceleration, and cornering forces instantly.

Riders can change suspension settings using handlebar controls while racing. This allows real-time adjustments for different track sections or changing conditions.

Electronic suspension helps maintain consistent tire contact with the track surface. Better tire contact improves both grip and tire wear patterns.

The systems reduce the physical demands on riders during long races. Electronic suspension absorbs more impacts and vibrations than traditional systems alone.