The diesel engine changed how we move people and goods around the world. When Rudolf Diesel created his engine in the late 1800s, he probably didn’t realize how much it would transform transportation.

Diesel engines revolutionized transportation by offering better fuel efficiency, more durability, and greater torque than gasoline engines, making them ideal for trucks, ships, trains, and heavy machinery.

This remarkable invention quickly spread beyond its industrial origins. By the 1920s, diesel engines were powering commercial vehicles, and by the 1930s, they had made their way into passenger cars. Their ability to deliver power more efficiently than steam engines led to widespread adoption in locomotives, ships, and factories. The diesel engine’s lower refining cost and reduced risk of explosions due to fewer fumes also contributed to its popularity.

Key Takeaways

- Rudolf Diesel’s invention provided superior efficiency that transformed multiple transportation sectors, from shipping to railways to commercial trucking.

- Diesel engines deliver more power with less fuel consumption, making them economically advantageous for heavy transportation applications.

- The diesel engine’s impact extends beyond vehicles to include industrial applications, reshaping global trade and economic development.

Historical Development of the Diesel Engine

The diesel engine emerged as a transformative technology in the late 19th century and evolved significantly through the 20th century, profoundly changing transportation worldwide. Its development represented a major leap in efficiency compared to steam and early gasoline engines.

Invention by Rudolf Diesel

Rudolf Diesel, a German engineer, created the diesel engine in the 1890s while seeking a more efficient alternative to steam power. His goal was to design a heat engine that could convert more fuel energy into work than existing technologies.

In 1892, Diesel received his first patent for the engine concept. After years of experimentation, he demonstrated a working prototype in 1897 that achieved approximately 26% efficiency—significantly better than steam engines of that era.

The early diesel engine utilized compression ignition rather than spark plugs. This fundamental design compressed air to high temperatures, then injected fuel which ignited automatically due to the heat of compression.

Despite initial successes, Diesel faced numerous technical challenges. His mysterious death in 1913 occurred before he could witness his invention’s full impact on global industry and transportation.

Evolution from Steam to Diesel Engines

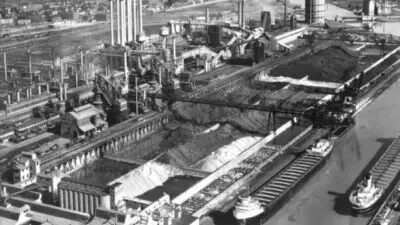

The transition from steam to diesel power represented a major technological shift in the early 20th century. Early diesel engines were primarily used in stationary applications due to their size and weight limitations.

By the 1920s, engineers had developed high-speed diesel engines suitable for commercial vehicles, marking a crucial advancement. The 1930s saw these engines adapted for passenger cars, though widespread adoption came later.

Diesel technology offered compelling advantages over steam:

- Greater thermal efficiency

- No need for constant water supply

- Reduced maintenance requirements

- Longer operating range

World War II accelerated diesel development for military applications. Post-war innovations included turbocharging, electronic fuel injection, and emissions control systems that expanded diesel’s applications.

Impact on the Locomotive Industry

Diesel locomotives revolutionized rail transport beginning in the 1930s, gradually replacing steam engines that had dominated for over a century. Diesel-electric locomotives combined diesel engines with electric generators to power traction motors.

The rail industry saw dramatic improvements with diesel adoption:

- Reduced operating costs: 50-60% lower than steam

- Increased reliability: Fewer breakdowns and maintenance requirements

- Higher availability: No need for frequent water stops or ash removal

- Improved power-to-weight ratio: More pulling capacity for freight

Electro-Motive Division (EMD) of General Motors played a pivotal role in this transformation, introducing successful diesel locomotives that demonstrated clear superiority over steam power. By the 1950s, diesel engines had largely replaced steam in most American and European rail networks.

This transition eliminated thousands of coal-shoveling jobs but created new skilled positions in diesel maintenance and operations, reshaping the workforce of the locomotive industry.

Diesel Engine Fundamentals

Diesel engines operate using different principles than gasoline engines, offering unique advantages in efficiency and power delivery. These robust internal combustion engines function through compression-ignition rather than spark ignition, creating a distinct operational profile.

Comparison with Gasoline Engines

Diesel engines are significantly more efficient than their gasoline counterparts, achieving up to 50% efficiency in modern designs compared to gasoline engines’ lower efficiency ratings. This means diesel vehicles can travel farther on the same amount of fuel.

Diesel engines produce greater torque at lower RPMs, making them ideal for heavy-duty applications like trucks, buses, and construction equipment. This torque advantage makes diesel perfect for pulling heavy loads.

The fuel itself contains more energy per gallon than gasoline, contributing to diesel’s efficiency advantage. Modern diesel engines also tend to be more durable and longer-lasting than gasoline engines, though they typically cost more upfront.

Compression-Ignition Mechanism

Unlike gasoline engines that use spark plugs, diesel engines rely on compression-ignition. The engine compresses air to extremely high pressures, causing it to heat up significantly—often exceeding 1000°F (538°C).

When diesel fuel is injected into this super-heated compressed air, it ignites spontaneously without needing a spark. This process is known as compression-ignition and is fundamental to how diesel engines operate.

The higher compression ratios in diesel engines (typically 14:1 to 25:1 compared to 8:1 to 12:1 in gasoline engines) contribute to their superior thermal efficiency. This converts chemical energy in the fuel to mechanical energy more effectively.

Fuel Injection System Breakdown

The fuel injection system is critical to diesel engine performance. It precisely delivers diesel fuel into the combustion chamber at exactly the right moment in the compression cycle.

Common injection systems include:

- Direct injection: Fuel sprays directly into the main combustion chamber

- Indirect injection: Fuel enters a pre-chamber before the main combustion chamber

- Common rail systems: Maintain constant high pressure, allowing multiple precise injections per cycle

Modern diesel engines use electronic control units (ECUs) to optimize injection timing and quantity based on engine load, speed, and temperature. This precise control helps maximize efficiency while minimizing emissions.

Advancements in injection technology have dramatically improved diesel performance, reducing the noise, smoke, and pollution that once characterized older diesel engines.

The Diesel Engine in Transportation

Diesel engines transformed transportation with their superior efficiency and robust power delivery. These engines provided the torque and durability needed for moving heavy loads while consuming less fuel than their gasoline counterparts.

Heavy-Duty and Industrial Applications

Diesel engines quickly became the preferred power source for heavy-duty transportation after their introduction. The diesel engine’s superior efficiency (reaching over 50% in modern designs) made it ideal for applications requiring sustained power over long periods.

Trucks, buses, and trains benefited enormously from diesel technology. The high torque output at low engine speeds made diesel perfect for hauling heavy loads, while the durability of these engines meant they could run for hundreds of thousands of miles with proper maintenance.

In construction and mining, diesel engines power equipment like bulldozers, excavators, and massive haul trucks. These industries rely on diesel’s reliability and power density in demanding conditions.

Railway transportation was revolutionized by diesel locomotives, which gradually replaced steam engines throughout the 20th century. Diesel-electric locomotives combine the efficiency of diesel with the smooth power delivery of electric motors.

Revolutionizing the Automobile Sector

Diesel engines entered the passenger car market in the 1930s, though their adoption was initially slow. Early diesel cars were often noisy, smoky, and less responsive than gasoline vehicles.

Technological advances in the 1970s and 1980s dramatically improved diesel performance in automobiles. High-speed diesel engines became quieter, cleaner, and more powerful, making them viable alternatives to gasoline engines.

European manufacturers particularly embraced diesel technology, with companies like Mercedes-Benz, Volkswagen, and Peugeot developing sophisticated diesel cars. These vehicles offered exceptional fuel economy and longevity.

The introduction of turbocharging and direct injection significantly boosted diesel performance. Modern diesel cars provide impressive torque for acceleration while maintaining efficiency advantages over comparable gasoline models.

Electronic control systems have further refined diesel operation, reducing emissions and improving drivability. Today’s diesel automobiles offer a compelling balance of power, efficiency, and durability.

Advances in Maritime and Aviation Engines

The shipping industry has relied heavily on diesel power since the early 20th century. Large container ships use massive slow-speed diesel engines that can exceed 100,000 horsepower while maintaining remarkable efficiency.

Maritime diesel engines have evolved to handle various fuel types, including heavy bunker fuels and cleaner alternatives. This versatility has been crucial for adapting to changing environmental regulations.

Diesel engines power everything from small fishing boats to massive cruise ships. Their reliability and relatively simple maintenance make them ideal for vessels that may be at sea for extended periods.

In aviation, diesel engines have found applications in smaller aircraft and unmanned aerial vehicles. Their excellent fuel economy extends range, while their ability to use jet fuel (similar to diesel) simplifies logistics at airports.

Modern diesel technology continues to advance with computer-controlled injection systems, reducing emissions while improving performance. These innovations ensure diesel engines remain relevant despite competition from gas turbines and electric propulsion.

Environmental and Health Impacts of Diesel Engines

Diesel engines produce significant pollutants that affect both the environment and human health. While diesel engines offer fuel efficiency, their emissions have led to increasing regulations and technological innovations to reduce harmful impacts.

Emissions and Air Pollution

Diesel engines emit several key pollutants that contribute to air quality issues. They are major sources of nitrogen oxides (NOx) and particulate matter (PM2.5). Heavy-duty diesel vehicles account for approximately 20% of all NOx and 25% of PM2.5 pollution.

These emissions contribute significantly to smog formation and reduced visibility in urban areas. The black smoke often associated with older diesel vehicles consists primarily of carbon particles and unburned fuel.

Diesel engines also produce carbon dioxide (CO2), which contributes to climate change. Although diesel engines typically produce less CO2 than gasoline engines due to better fuel efficiency, their overall environmental impact remains substantial.

The environmental effects extend beyond air quality issues. Diesel pollutants can contaminate soil and water systems when particles settle from the air, creating a broader environmental footprint.

Effects on Human Health

The health impacts of diesel emissions are significant and well-documented. Diesel pollution has been linked to the development of cancer, particularly lung cancer, as the World Health Organization classified diesel exhaust as a carcinogen in 2012.

Exposure to diesel particulate matter can trigger or worsen respiratory conditions like asthma and bronchitis. These fine particles can penetrate deep into lung tissue, causing inflammation and reducing lung function.

Long-term exposure increases risks of cardiovascular disease and premature death. The smallest particles can enter the bloodstream, affecting the heart and other organs.

Urban populations and those living near major transportation corridors experience higher exposure levels. People who work with or around diesel equipment, such as truck drivers and construction workers, face increased occupational risks.

Children and the elderly are particularly vulnerable to these health effects due to developing or declining respiratory systems.

Regulations and Technological Responses

Stringent emissions standards have been implemented worldwide to reduce diesel pollution. In the United States, the Environmental Protection Agency (EPA) and in Europe, Euro emissions standards have progressively tightened allowable emission levels.

Modern technological solutions include:

- Diesel Particulate Filters (DPFs) – trap and remove particulate matter

- Selective Catalytic Reduction (SCR) – reduces NOx emissions using urea-based solutions

- Exhaust Gas Recirculation (EGR) – lowers combustion temperatures to reduce NOx formation

- Advanced fuel injection systems – improve combustion efficiency

These technologies have helped newer diesel engines achieve near-zero emissions while maintaining or improving fuel efficiency. The latest standards require emissions reductions of more than 90% compared to pre-regulated diesel engines.

Alternative fuel options like biodiesel and renewable diesel offer additional pathways to reduce the environmental impact of diesel engines while utilizing existing infrastructure.

Advancements in Fuel Efficiency and Alternative Fuels

Diesel engines have undergone significant improvements in fuel efficiency while adapting to environmental concerns through alternative fuel options. These advancements have helped maintain diesel’s relevance despite growing competition from other technologies.

Improving Fuel Economy

Modern diesel engines achieve remarkably better fuel economy than their predecessors. Engineers have implemented several key technologies to boost efficiency:

- Common rail direct injection systems that precisely control fuel delivery

- Turbocharging and intercooling to maximize power from each fuel drop

- Electronic engine management systems that optimize combustion

- Advanced materials reducing engine weight while maintaining durability

These improvements have made diesel engines more efficient partly due to their unique compression ignition process. Unlike gasoline engines that use spark plugs, diesel engines compress air until it’s hot enough to ignite the fuel when injected.

Fuel economy gains also come from reduced friction components and better thermal management. Today’s diesel vehicles typically achieve 20-30% better fuel economy than comparable gasoline models.

Biodiesel and Renewable Diesel Fuels

Alternative fuels have revolutionized the diesel landscape by offering more sustainable options. Biodiesel, produced from renewable sources like vegetable oils and animal fats, reduces carbon emissions while providing similar performance to conventional diesel.

Key developments include:

- B5, B20, and B100 blends (containing 5%, 20%, and 100% biodiesel respectively)

- Renewable diesel made through hydrotreatment processes

- Waste-to-fuel technologies using cooking oil and agricultural byproducts

These fuels often require minimal or no engine modifications, making them practical alternatives. The construction industry has particularly benefited from these advancements, with alternative diesel fuels helping reduce emissions while maintaining power.

Renewable diesel represents the newest advancement, chemically identical to petroleum diesel but with a significantly smaller carbon footprint.

Hybrid and Electric Vehicles as Competitors

The rise of hybrid and electric technologies presents both challenges and opportunities for diesel engines. Diesel-electric hybrid systems combine diesel’s torque and efficiency with electric motors’ zero-emission capability.

Notable developments include:

| Technology | Advantages | Applications |

|---|---|---|

| Mild Hybrid | Improved fuel economy with minimal cost increase | Passenger cars, light trucks |

| Full Hybrid | Significant fuel savings, reduced emissions | Commercial vehicles, buses |

| Plug-in Hybrid | Extended electric-only range | Premium vehicles, delivery vans |

Pure electric vehicles have begun competing in sectors traditionally dominated by diesel, particularly in urban delivery and public transportation. However, diesel remains dominant in long-haul trucking and heavy machinery due to its energy density and refueling speed advantages.

Many manufacturers now offer electric alternatives alongside their diesel fleets, recognizing that different applications require different power solutions.

The Future of Diesel in Agriculture and Construction

Diesel engines remain essential in powering modern agriculture and construction industries despite ongoing technological changes. Their durability and efficiency continue to provide the reliable power needed for demanding work environments.

Diesel’s Role in Modern Agriculture

Diesel power is the backbone of modern farming, with approximately 75% of farm equipment running on diesel fuel. This dominance stems from diesel engines’ superior torque and reliability in harsh conditions.

Today’s agricultural diesel engines are becoming more environmentally friendly while maintaining their power advantage. Manufacturers are developing engines with reduced emissions and improved fuel efficiency to meet stricter regulations.

Smart farming practices increasingly rely on diesel generators for irrigation systems, with diesel currently powering about 20% of water pumps used for irrigation. This highlights diesel’s continuing importance in food production worldwide.

Innovations in biodiesel and renewable diesel fuels offer farmers more sustainable options without requiring significant equipment changes. These alternative fuels help reduce carbon footprints while utilizing existing diesel infrastructure.

Construction Equipment and Diesel Efficiency

Construction sites depend heavily on diesel-powered equipment for their daily operations. Excavators, bulldozers, and cranes all benefit from diesel’s high torque output and efficiency in heavy-duty applications.

Manufacturers are focusing on three key areas for improvement:

- Emission reduction technologies including advanced particulate filters

- Fuel efficiency enhancements through electronic fuel injection

- Hybrid systems combining diesel power with electric components

The construction industry values diesel engines for their unmatched durability and power-to-weight ratio. Even as electrification grows in other sectors, diesel remains essential for heavy machinery due to its ability to deliver consistent power over long working hours.

Modern diesel construction equipment now incorporates sophisticated engine management systems that optimize performance while reducing fuel consumption. These improvements keep diesel competitive even as alternative power sources emerge.

Frequently Asked Questions

Diesel engines transformed transportation through enhanced efficiency, power, and reliability. These innovations created new possibilities for long-distance travel, commercial shipping, and economic development worldwide.

What are the key differences between diesel and petrol engine automobiles in terms of revolutionizing transportation?

Diesel engines offer up to twice the efficiency of gasoline engines, allowing vehicles to travel farther on the same amount of fuel. This efficiency made diesel particularly valuable for commercial transportation where fuel costs significantly impact profitability.

Diesel engines produce greater torque at lower RPMs, making them ideal for moving heavy loads. This characteristic revolutionized trucking and shipping industries by enabling the transport of heavier cargo over longer distances.

The durability of diesel engines typically exceeds that of gasoline counterparts, with many commercial diesel engines designed to run for 1 million miles before major overhaul. This longevity changed the economics of fleet management and long-haul transportation.

What technological advancements did the first diesel engine trucks introduce to the transportation industry?

Early diesel trucks introduced compression ignition technology that eliminated the need for spark plugs, creating more reliable operation in various weather conditions. This reliability transformed commercial transportation by reducing breakdowns and delays.

The first diesel trucks demonstrated superior fuel economy, which extended the operational range of commercial vehicles. This extended range opened new trade routes and market opportunities previously limited by fuel constraints.

Direct injection systems in early diesel trucks provided more complete fuel combustion, resulting in greater power output. This increased power capacity allowed for larger, heavier vehicles that could transport more goods per trip.

How did diesel engine innovation contribute to the development of early twentieth-century logistics and trade?

Diesel-powered locomotives replaced steam engines, dramatically increasing the efficiency and reliability of railway systems. This transformation supported the expansion of national and international trade networks through faster, more dependable freight transport.

Diesel engines enabled electricity generation in remote locations, supporting infrastructure development in previously inaccessible areas. These power systems facilitated the construction of warehouses, distribution centers, and transportation hubs.

Maritime shipping underwent profound changes as diesel engines replaced coal-fired steam engines in commercial vessels. The switch increased cargo capacity, reduced fuel costs, and extended operational ranges of shipping fleets.

In what ways did the introduction of diesel engines impact environmental and economic factors within the automobile industry?

Diesel engines’ superior fuel efficiency reduced transportation costs across the supply chain, leading to lower consumer prices for goods. This economic advantage accelerated the adoption of diesel technology in commercial fleets.

The lower carbon dioxide emissions of diesel engines (compared to equivalent gasoline engines) initially positioned them as an environmentally conscious choice. Many countries introduced tax incentives for diesel vehicles to reduce overall carbon emissions.

Later recognition of particulate matter and nitrogen oxide emissions from diesel engines prompted technological innovations like particulate filters and selective catalytic reduction systems. These developments pushed the automobile industry toward cleaner combustion technologies.

How has the ongoing evolution of diesel engines influenced modern vehicle design and fuel efficiency standards?

Modern turbocharging and intercooling technologies have dramatically improved diesel engine performance while reducing emissions. These advancements have shaped international emissions standards and testing protocols for all vehicles.

Diesel-powered cars gained popularity for long-distance travel due to their excellent torque and efficiency. This consumer preference influenced manufacturers to develop more refined diesel powertrains with reduced noise and vibration.

Computer-controlled fuel injection systems have optimized diesel combustion, leading to cleaner, more efficient engines. These electronic management systems have become standard across all engine types, improving overall vehicle efficiency.

What significant societal changes resulted from the widespread adoption of diesel-powered transportation?

Diesel-powered public transportation expanded access to affordable mobility in many regions. Bus networks and commuter trains, powered by diesel engines, connected communities and expanded labor markets.

The reliability of diesel engines enabled consistent delivery schedules for goods. This transformation changed retail and consumer expectations. Just-in-time inventory systems became possible, changing how businesses operated and consumers shopped.

Rural and remote communities gained better access to goods and services through diesel-powered transportation networks. This accessibility reduced geographic isolation and supported economic development in previously underserved regions.