Keeping your motorcycle running smoothly means taking care of the carburetor, the heart of your fuel system. This small but crucial component mixes air and fuel in the right proportions for proper combustion. A clean carburetor ensures optimal performance, better fuel efficiency, and extends the life of your motorcycle engine.

When your bike starts showing signs like rough idling, poor acceleration, or difficulty starting, it’s often the carburetor asking for attention. Regular inspection and cleaning can prevent these issues before they leave you stranded. Most riders can learn to perform basic carburetor maintenance with the right tools and a bit of patience.

Cleaning a motorcycle carburetor might seem intimidating at first, but it’s a manageable task even for beginners. With some basic mechanical knowledge and careful attention to detail, you can restore your carburetor’s performance and keep your bike running at its best for years to come.

Key Takeaways

- Regular carburetor inspection prevents common motorcycle problems like poor starting, rough idling, and decreased fuel efficiency.

- Proper cleaning requires careful disassembly, quality cleaning solutions, and attention to small components like jets and float needles.

- Reassembling with new gaskets and correct adjustments ensures optimal engine performance and extends the life of your motorcycle.

Understanding Motorcycle Carburetors

Motorcycle carburetors are precision instruments that mix fuel and air in the right proportions for combustion. These mechanical devices operate on basic principles but require proper maintenance to ensure your bike runs smoothly.

Key Components and Their Functions

The float bowl is the carburetor’s fuel reservoir, with a floating mechanism that maintains proper fuel levels. When fuel drops below a certain point, the float allows more fuel to enter.

The jets are calibrated openings that control fuel flow. Main jets handle higher speeds, while pilot jets manage idle and low-speed running. Their sizes directly affect how rich or lean your engine runs.

The throttle slide controls airflow into the engine. When you twist the throttle grip, this component moves up or down to allow more or less air into the mix.

Idle screws adjust how your engine runs at rest, while air-fuel mixture screws fine-tune the ratio of these elements. These adjustments are critical for proper carburetor function.

Other important parts include:

- Choke mechanism (for cold starts)

- Needle and needle jet (for mid-range throttle positions)

- Venturi (creates vacuum for fuel atomization)

How Carburetors Affect Engine Performance

A properly tuned carburetor delivers the ideal air-fuel mixture across all riding conditions. This mixture typically ranges between 12:1 and 15:1 (air to fuel) for optimal performance.

When carburetors are dirty or improperly adjusted, you’ll notice symptoms like:

- Rough idle

- Poor acceleration

- Reduced fuel efficiency

- Hesitation when opening throttle

- Hard starting, especially when cold

Even minor carburetor issues can reduce power output by 10-15%. Carburetor problems often worsen over time, as fuel residue builds up in passages and jets.

Modern motorcycles with well-maintained carburetors can achieve excellent fuel efficiency while still delivering responsive throttle control. The precision of your carburetor settings directly influences how your bike performs at different RPMs and riding conditions.

Preparing for Inspection and Cleaning

Before diving into carburetor maintenance, proper preparation is crucial for safety and success. Having the right tools, understanding safety protocols, and knowing how to properly access your carburetor will make the job much easier and more effective.

Essential Tools and Materials

To properly clean a motorcycle carburetor, you’ll need several specific tools and materials:

- Basic Tools: Phillips and flathead screwdrivers, pliers, socket set, and wrenches sized for your specific motorcycle model

- Cleaning Supplies: Quality carburetor cleaner or parts cleaner, cleaning brushes, and compressed air

- Replacement Items: Carb rebuild kit with new gaskets, O-rings, and jets appropriate for your motorcycle model

- Workspace Items: Clean rags, drain pan, small containers for parts, and a well-lit workspace

A digital camera or smartphone is invaluable for taking reference photos before disassembly. This helps track the original position of parts and connections.

Consider purchasing a fuel additive for future maintenance to help prevent carburetor clogging.

Safety Considerations

Carburetor cleaning involves handling potentially harmful chemicals and flammable materials. Safety must be the top priority.

Workspace Requirements:

- Work in a well-ventilated area to avoid inhaling fumes from cleaning solutions

- Keep a fire extinguisher nearby as you’ll be handling flammable materials

- Ensure adequate lighting to see small parts clearly

Personal Protection:

- Wear nitrile gloves to protect skin from harsh chemicals in carb cleaner

- Use safety glasses to shield eyes from splashing cleaning solutions

- Consider a respirator mask if working in confined spaces

Always disconnect the battery before beginning work to prevent electrical shorts. Turn the fuel petcock to the “Off” position to stop fuel flow before removing any fuel lines.

Locating and Removing the Carburetor

The carburetor is typically located between the engine and the air intake filters on most motorcycles. Accessing it requires some disassembly.

First, park your motorcycle on a level surface and turn off the engine. Allow the engine to cool completely before starting work.

Removal Steps:

- Remove the seat and fuel tank if necessary to gain clear access

- Locate and disconnect air intake filters and air box connections

- Identify and label fuel lines before disconnecting them to ensure proper reconnection

- Take photos of the carburetor’s position and all connections before removal

- Loosen and remove throttle cables and choke cables if present

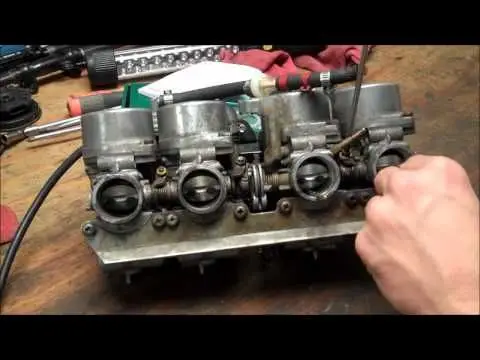

For multi-carburetor setups, keep track of which carburetor goes where. Some riders mark them with tape or a marker. Remove mounting bolts carefully, noting their positions for reassembly.

Gently wiggle the carburetor free without forcing it. Intake boots can become stiff with age, making removal challenging.

Inspection Before Cleaning

Before diving into carburetor cleaning, proper inspection is crucial to identify problems and confirm that the carburetor truly needs cleaning. Examining key indicators will help determine the exact issues affecting your motorcycle’s performance.

Common Signs of a Dirty Carburetor

A dirty carburetor often announces itself through noticeable performance issues. The most common indicator is rough idling, where the engine struggles to maintain consistent speed at rest.

You might also notice hard starting or the engine requiring multiple attempts before firing up. This happens when dirt restricts proper fuel flow.

Poor throttle response is another telltale sign. When you twist the throttle and experience a delay or hesitation, your carburetor may be struggling to deliver the correct fuel mixture.

Watch for black smoke from the exhaust, indicating an overly rich fuel mixture. This happens when dirt prevents the carburetor from properly regulating fuel.

Decreased fuel efficiency often accompanies carburetor problems. If you’re suddenly getting fewer miles per gallon, your carburetor might be delivering too much fuel.

Problems That Can Arise

Neglected carburetor issues can develop into more serious problems affecting overall engine performance. Fuel jets can become completely clogged, preventing proper fuel delivery and potentially leaving you stranded.

Float problems might cause fuel leaks or flooding. If your motorcycle smells strongly of fuel or you notice gasoline dripping, inspect the float mechanism immediately.

Airflow restrictions can develop when dirt accumulates on air passages, creating an improper air-fuel ratio. This leads to poor combustion and reduced power output.

The idle circuit is particularly susceptible to clogging since it deals with small amounts of fuel. When compromised, stable idle becomes impossible to maintain.

Gaskets and O-rings can deteriorate over time, causing air leaks that disrupt the carefully calibrated fuel mixture. Look for fuel seepage around seals.

Disassembling the Carburetor

Taking apart a motorcycle carburetor requires careful attention to detail and a methodical approach. Proper disassembly ensures you can thoroughly clean all components and identify any worn parts that need replacement.

Proper Disassembly Techniques

Before starting, place a clean cloth on your work surface to prevent losing small parts. Take clear photos of the carburetor from multiple angles before disassembly – these will be invaluable during reassembly.

Begin by removing the float bowl, usually secured by 3-4 screws on the bottom of the carburetor. Handle the bowl carefully to avoid damaging the gasket that seals the float bowl to the rest of the carburetor.

Next, remove the float by extracting the pivot pin. The float should come out easily, revealing the needle valve. This valve controls fuel flow into the carburetor.

Remove all jets and passages with the appropriate screwdriver. Different carburetors have various jet types:

- Main jet

- Pilot jet

- Needle jet

- Air jets

Take care not to strip the soft brass threads of jets when removing them. If a jet is stubborn, apply penetrating oil and wait before trying again.

Organizing and Inspecting Components

Create a systematic arrangement for all carburetor parts as you remove them. Use an organization tray with labeled compartments or egg cartons to keep track of small pieces.

As each component comes out, examine it for:

- Corrosion or oxidation

- Physical damage

- Blockages in jets and passages

- Worn O-rings or gaskets

Hold jets up to a light source to check if light passes through cleanly. If not, these passages are clogged and require thorough cleaning. Never use wire or metal tools to clear jets as this can alter their precise dimensions.

The float should move freely and be free from cracks or fuel absorption. Inspect all gaskets and O-rings for deterioration – these typically need replacement during a complete carburetor rebuild.

Document any issues you find for each part to create a replacement shopping list before reassembly.

Cleaning Process and Best Practices

Properly cleaning your motorcycle’s carburetor requires attention to detail and the right techniques. The cleaning process removes performance-robbing deposits that prevent proper fuel atomization and disrupt the air-fuel mixture.

Cleaning the Jets and Passages

Jets and passages are critical components that control fuel flow through the carburetor. These tiny openings clog easily with varnish and debris.

Start by soaking jets in quality carburetor cleaner for 30-60 minutes. Never use wire or metal objects to clean jets as they can alter the precise opening size.

Instead, use compressed air to blow through jets in the opposite direction of normal fuel flow. Hold jets up to light to verify they’re clear—you should see light passing through cleanly.

For stubborn clogs, an ultrasonic cleaner provides excellent results through a process called cavitation, which removes built-up deposits without damaging delicate parts.

Check each passage with thin cleaning brushes designed for carburetors. Ensure idle circuits and emulsion tubes are thoroughly cleaned as they affect idle quality and throttle response.

Removing Dirt, Grime, and Deposits

External carburetor surfaces collect oil, dust, and grime that can eventually work their way inside. Clean these surfaces with a soft brush and appropriate solvent.

For the carburetor body:

- Spray: Apply carburetor cleaner to loosen grime

- Brush: Use a soft-bristled brush for stubborn areas

- Wipe: Remove loosened deposits with a clean lint-free cloth

The float bowl often contains sediment and fuel varnish. Empty and clean it thoroughly, inspecting for corrosion or damage.

Carefully clean needle valves and seats using cotton swabs dipped in cleaner. These components control fuel flow and must be free of any residue that could affect their operation.

For difficult deposits, allow parts to soak longer, but monitor rubber or plastic components as prolonged exposure to harsh solvents can cause damage.

Selecting the Right Cleaning Solutions

Not all cleaning products are created equal when it comes to effective carburetor maintenance. Choose solutions specifically formulated for motorcycle carburetors.

Recommended cleaning options:

- Commercial carburetor cleaners (aerosol or liquid)

- Dedicated motorcycle carb cleaners

- Ultrasonic cleaning solutions (gentler on delicate parts)

Avoid general-purpose degreasers as they may not dissolve fuel varnish effectively. Many riders prefer cleaners with lubricating properties that help protect metal surfaces after cleaning.

For regular maintenance, consider milder solutions that won’t damage seals or gaskets. Harsh cleaners should be reserved for complete rebuilds when parts are fully disassembled.

Always use cleaning solutions in a well-ventilated area and wear appropriate protective gloves to prevent skin irritation. Dispose of used cleaning solutions properly according to local regulations.

Reassembling and Installing the Carburetor

Putting your carburetor back together properly ensures optimal engine performance and prevents fuel leaks. Careful attention to detail during reassembly will save you time and frustration later.

Proper Reassembly Steps

Begin by laying out all clean carburetor parts in an organized manner. Check your manufacturer’s manual for the correct assembly order. If you purchased a carb rebuild kit, now is the time to replace worn gaskets, O-rings, and jets.

Install the float needle valve first, followed by the float assembly. Set the float height according to specifications using a digital caliper for accuracy. This measurement is critical for proper fuel flow.

Next, install the jets and passages in the correct sequence. Make sure each jet is clean and the correct size for your motorcycle model. Thread carefully to avoid damaging the delicate threads.

Reassemble the throttle plate and choke mechanism, ensuring smooth operation throughout their range of motion. Apply a small amount of lubricant to pivot points if recommended.

Reconnecting Fuel and Air Systems

Once the carburetor is reassembled, it’s time to reinstall it on your motorcycle. Position it carefully on the intake manifold, ensuring the gasket is properly seated to prevent air leaks.

Tighten all mounting bolts in a criss-cross pattern to ensure even pressure. Don’t overtighten as this can warp the carburetor body or damage gaskets.

Connect fuel lines securely, making sure there are no kinks or pinch points. Install a new fuel filter if your system uses one. This prevents debris from clogging your newly cleaned carburetor.

Reattach all vacuum lines according to your reference photos or manual diagrams. These are often different sizes to prevent incorrect connections.

Finally, connect the throttle and choke cables, adjusting them for proper operation. Install a clean air filter to protect your carburetor from contaminants.

Adjustments and Final Checks

After cleaning your carburetor, proper adjustment is crucial for your motorcycle to run smoothly. These final steps ensure optimal fuel delivery and engine response before you hit the road.

Tuning the Air-Fuel Mixture

The air-fuel mixture is critical for proper combustion and engine performance. Locate the air-fuel mixture screw on your carburetor – it’s typically a small brass screw on the side or bottom of the carb body.

Turn the screw gently clockwise until it seats (don’t force it), then back it out 1.5-2 turns as a baseline. This starting point works for most motorcycles but check your service manual for exact specifications.

For a richer mixture (more fuel), turn the screw counterclockwise. For a leaner mixture (less fuel), turn it clockwise. Make adjustments in small 1/4 turn increments.

Listen for changes in engine sound – a smooth, steady idle indicates proper mixture. If the engine hesitates or sputters, your mixture needs adjustment.

Testing Idle Speed and Throttle Response

The idle speed adjustment directly affects how your motorcycle runs at rest. Find the idle screw that controls the throttle slide position at rest – usually located near the throttle cable connection.

Start your engine and let it warm up for 5-10 minutes. Adjust the idle screw to achieve a steady idle speed according to your service manual specifications (typically 1000-1300 RPM).

Test throttle response by gently rolling the throttle. You should feel smooth acceleration without hesitation or bogging. If the engine hesitates, your carburetor may need further adjustment.

Make small adjustments to both the air-fuel mixture and idle speed screws until you achieve the best balance. These settings often work together – changing one may require adjusting the other.

Preventive Maintenance and Long-Term Care

Regular maintenance prevents most carburetor problems before they start. The right cleaning schedule and proper attention to fuel and air systems will significantly extend your motorcycle’s performance and reliability.

Routine Carburetor Cleaning

Clean your motorcycle carburetor every 6-12 months depending on riding conditions. Bikes used in dusty environments need more frequent attention.

For preventive maintenance, clean every 2,000-3,000 miles as part of your regular servicing schedule. This prevents varnish buildup that causes poor performance.

Always clean the carburetor before long-term storage. Residual fuel can harden and clog passages during inactivity.

Look for these warning signs that indicate cleaning is needed:

- Rough idling or stalling

- Poor acceleration or hesitation

- Decreased fuel efficiency

- Black smoke from exhaust

Use quality carburetor cleaners specifically formulated for motorcycles. Avoid harsh chemicals that may damage rubber components or gaskets.

Fuel and Air Filter Maintenance

Replace your fuel filter every 10,000 miles or annually. A clogged filter restricts flow and causes lean running conditions.

Use only clean, fresh fuel. Old gasoline forms deposits that clog jets and passages. Add a quality fuel additive with stabilizers when storing your motorcycle for extended periods.

Air filters require regular inspection and cleaning. A dirty air filter restricts airflow, creating a rich mixture that wastes fuel and reduces power.

Paper air intake filters should be replaced according to manufacturer recommendations. Foam filters can be cleaned with specialized cleaners and reused.

Keep the entire air intake system sealed properly. Even small leaks can introduce unfiltered air and dirt into your carburetor, accelerating wear.

Frequently Asked Questions

Riders often have specific questions about carburetor maintenance and troubleshooting. These answers provide detailed guidance on common carburetor concerns to help keep your motorcycle running smoothly.

What are the steps for disassembling a motorcycle carburetor for cleaning?

Begin by removing the carburetor from the motorcycle and draining all fuel. Take clear photos of the assembled carburetor to reference during reassembly.

Remove the float bowl by unscrewing the retaining screws or bolts. Carefully extract the float, needle valve, and main jet assembly.

Remove the smaller jets, paying attention to their specific locations. Use the proper sized screwdrivers to avoid damaging the delicate brass components and keep all parts organized in a clean container.

Can a carburetor be effectively cleaned without removal from the motorcycle?

Yes, you can perform a basic carburetor cleaning without full removal. This method involves disconnecting the fuel line and using a quality carburetor cleaner spray.

Spray the cleaner into the air intake while the engine runs at idle to dissolve carbon deposits and varnish. For motorcycles with accessible float bowls, you can drain and clean them while the carburetor remains mounted.

This approach works for minor clogs and regular maintenance but won’t address severe contamination or deeply embedded debris that requires complete disassembly.

What symptoms indicate a dirty or malfunctioning motorcycle carburetor?

Poor idle quality or an engine that won’t idle at all often indicates carburetor issues. Hesitation during acceleration and rough running are also common symptoms.

Excessive fuel consumption or visible fuel leaks suggest float or needle valve problems. Black smoke from the exhaust typically points to a rich fuel mixture caused by carburetor maladjustment or clogging.

Starting difficulties, especially when the engine is warm, frequently stem from carburetor problems. Surging at steady throttle positions is another telltale sign of carburetor issues.

Which cleaning solutions are recommended for motorcycle carburetor maintenance?

Commercial carburetor cleaners from reputable brands are highly effective for dissolving varnish and gum deposits. These products contain solvents specifically formulated to break down fuel residue without damaging rubber or plastic components.

Ultrasonic cleaning represents a superior method for thorough carburetor cleaning. This technology uses sound waves to create microscopic bubbles that dislodge contaminants from hard-to-reach areas.

Never use wire brushes on jets or orifices as they can alter critical dimensions. Compressed air is helpful for clearing passages after chemical cleaning.

How often should motorcycle carburetors be cleaned for optimal performance?

For regularly ridden motorcycles, a detailed maintenance schedule should include carburetor inspection every 5,000 miles or annually, whichever comes first.

Motorcycles stored for extended periods require more frequent attention, as fuel deterioration creates varnish that clogs small passages. Adding fuel stabilizer before storage significantly reduces this risk.

Riding conditions also influence cleaning frequency—dusty environments or poor fuel quality necessitate more regular maintenance.

What are common mistakes to avoid while cleaning a motorcycle carburetor?

Using improper tools that damage delicate jets and passages ranks among the most common errors. Always use correctly sized screwdrivers and never force stuck parts.

Failing to replace gaskets and O-rings leads to air leaks that cause performance issues. These rubber components become brittle over time and rarely reseal properly.

Incorrect reassembly sequence or improper float height adjustment will prevent proper functioning. Carburetors require precise adjustment of multiple settings to work correctly.

Rushing the cleaning process or skipping thorough rinsing of cleaning chemicals can leave residue that affects fuel flow. Patience and attention to detail are essential for successful carburetor maintenance.