The 1970s marked a turning point in automotive history when Japanese car makers transformed from minor players to global powerhouses. Rising from the ashes of post-war industrialization, companies like Toyota and Honda seized opportunities created by the oil crisis when American consumers sought fuel-efficient alternatives to gas-guzzling domestic models. Japan’s explosive entry into the global auto market permanently shifted the balance of power by focusing on fuel efficiency, reliability, and affordability.

This transformation didn’t happen by accident. Japanese manufacturers built their reputation through detail-oriented engineering and consistent quality. The statistics tell the story clearly: in 1970, Japanese imports represented just 1.4% of the U.S. market share, but this percentage grew dramatically throughout the decade as American consumers embraced these practical alternatives.

Key Takeaways

- Japanese automakers capitalized on the 1970s oil crisis by offering fuel-efficient alternatives that permanently changed consumer expectations.

- The focus on reliability, affordability, and innovation helped Japanese manufacturers gain significant market share in the United States and globally.

- Manufacturing innovations from Japan fundamentally changed how cars were built worldwide, establishing new industry standards that continue to influence production today.

Historical Context: Post-War Japan and the Automotive Boom

Japan’s journey from post-war devastation to automotive excellence exemplifies one of the most remarkable industrial transformations of the 20th century. The nation’s strategic approach to rebuilding its economy positioned automobiles as a centerpiece of its industrial policy.

Rebuilding the Japanese Economy

Following World War II, Japan faced enormous economic challenges. The country’s industrial base was largely destroyed, with manufacturing capacity reduced to approximately 10% of pre-war levels. This devastating situation created an urgent need for economic reinvention.

By the 1950s, Japan began focusing on strategic industries that could drive growth and generate export revenue. The automobile sector emerged as a priority because it combined multiple manufacturing disciplines and could create thousands of jobs.

The post-war recession actually worked as a catalyst, forcing Japanese companies to innovate with limited resources. This period of constraint taught Japanese manufacturers valuable lessons in efficiency and waste reduction—principles that would later become hallmarks of their production systems.

The Pioneers of Japanese Automotives

Toyota, Nissan, and Honda led Japan’s automotive revolution, though each took different paths to success. Toyota, founded as a loom manufacturer, pivoted to automobiles in the 1930s but gained significant momentum in the 1950s with models like the Crown.

Nissan (originally Datsun) focused on producing reliable, affordable vehicles for the domestic market before expanding internationally. Honda, a latecomer founded in 1948 as a motorcycle company, entered the automobile market in the 1960s with innovative designs.

These companies developed unique approaches to car manufacturing, with Toyota pioneering the revolutionary “lean production” system. This approach minimized waste, improved quality, and reduced inventory costs—principles that would later be adopted worldwide.

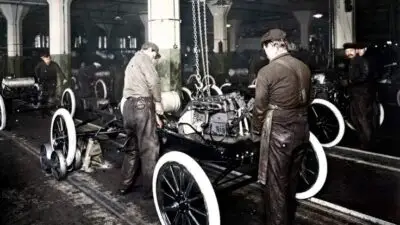

By the 1970s, Japan became the first country to extensively use robotics in vehicle manufacturing, dramatically improving precision and consistency.

Government Policies and Their Impact

The Japanese government played a crucial role in developing the automobile industry through strategic policies. The Ministry of International Trade and Industry (MITI) implemented protective tariffs that shielded domestic manufacturers from foreign competition during their growth phase.

Tax incentives encouraged research and development, while subsidized loans provided much-needed capital for expansion. The government also invested heavily in infrastructure, particularly the highway system, creating domestic demand for automobiles.

Additionally, strict quality standards were established, forcing manufacturers to meet high benchmarks. Export promotion policies helped Japanese companies gain footholds in international markets, particularly in the United States.

The “Administrative Guidance” approach—where government agencies worked collaboratively with industry rather than through direct regulation—created a unique public-private partnership that fostered innovation while maintaining strategic direction.

Innovations in Car Manufacturing

Japanese automakers introduced revolutionary manufacturing techniques that forever transformed the global auto industry. These innovations focused on efficiency, technology integration, and unprecedented quality standards that competitors scrambled to adopt.

Streamlining Production Processes

The Japanese approach to car manufacturing centered on the now-famous Just-In-Time system, pioneered by Toyota. This system dramatically reduced inventory costs by delivering parts exactly when needed in the production process.

Another breakthrough was the implementation of flexible manufacturing systems that could produce multiple car models on the same assembly line. This versatility gave Japanese companies a significant competitive advantage.

Workers participated in quality circles, where they contributed ideas for process improvements. This bottom-up approach engaged employees directly in solving problems and enhancing productivity.

Toyota’s kanban system used visual cards to control production flow and prevent wasteful overproduction. These methods reduced factory floor space needs by up to 50% compared to traditional manufacturing approaches.

Adoption of Electronics in Cars

Japanese manufacturers led the integration of electronic components in vehicles during the 1970s. Electronic fuel injection systems replaced carburetors, improving fuel efficiency when gas prices soared after oil crises.

Microprocessor-controlled engine management systems optimized performance while meeting increasingly strict emissions requirements. These innovations made Japanese cars particularly appealing during the energy crisis.

Cars began featuring electronic dashboards with digital displays, replacing traditional analog gauges. This technology shift established Japanese brands as forward-thinking and technologically advanced.

Japan’s strong electronics industry provided advantages in developing integrated circuits specifically designed for automotive applications. This expertise helped create more reliable and sophisticated vehicle systems.

Quality Control and Reliability

Statistical quality control methods transformed production standards in Japanese factories. These techniques identified problems before they reached consumers, reducing defects dramatically.

Japanese manufacturers implemented Total Quality Management (TQM) principles across all operations. This detail-oriented engineering approach focused on continual improvement rather than meeting minimum standards.

Consumer Reports and other publications began documenting Japanese vehicles’ superior reliability in the 1970s. This reputation for quality became a primary selling point that expanded market share substantially.

By the decade’s end, Japanese car brands had established unprecedented quality benchmarks. American manufacturers faced a painful reality: Japanese imports grew from 17.7% to 28% of US car sales, forcing domestic companies to completely rethink their manufacturing philosophies.

The Rise of Compact Cars

The global oil crisis of the 1970s created perfect conditions for Japan’s compact car revolution. Japanese automakers capitalized on consumer needs with vehicles that prioritized efficiency without sacrificing quality.

Fuel Efficiency and Design

Japanese manufacturers reimagined what cars could be during the 1970s energy crisis. When fuel prices soared, vehicles like the Honda Civic and Toyota Corolla offered impressive gas mileage that American models couldn’t match. These compact cars weren’t just fuel-efficient—they were reliable and affordable.

Japanese engineers focused on lightweight designs and smaller engines that maximized efficiency. The average Japanese compact delivered 25-35 mpg while many American cars struggled to reach 15 mpg.

Key design innovations included:

- Aerodynamic body styling

- Front-wheel drive configurations

- Smaller, more efficient engines

- Weight reduction techniques

Detail-oriented engineering became Japan’s competitive advantage. Their commitment to quality control dramatically reduced defects compared to American-made vehicles.

Market Shift: Embracing Smaller Vehicles

The 1973 oil embargo fundamentally changed American car buying habits. Consumers who once preferred large, powerful vehicles suddenly found themselves facing long gas lines and soaring fuel costs.

Japanese automakers were perfectly positioned for this shift. They had already mastered small car production while Detroit remained focused on larger models. By the mid-1970s, it became clear that fuel-efficient small cars were the answer to rising gasoline prices.

Market data tells the story:

| Year | Japanese Market Share in US |

|---|---|

| 1970 | Under 5% |

| 1975 | ~10% |

| 1980 | Over 20% |

American manufacturers attempted to compete with hastily designed compact models, but these often lacked the quality and reliability that Japanese vehicles offered. Consumers quickly recognized the difference.

Japanese brands built lasting customer loyalty through positive ownership experiences. Their focus on affordability without sacrificing quality resonated with budget-conscious buyers.

Environmental Regulations and Innovations

The 1970s marked a turning point for car manufacturers as environmental concerns led to stricter regulations. Japanese automakers turned these challenges into opportunities, positioning themselves as leaders in cleaner automotive technology.

Adapting to the Clean Air Act

The Clean Air Act of 1970 created tough new standards for vehicle emissions in the United States. This legislation forced all automakers to reduce harmful pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides.

Japanese manufacturers responded quickly to these changes. While American companies struggled with the new requirements, Japanese automakers pioneered fuel-efficient technology that naturally produced fewer emissions. Their smaller engines generated less pollution while using less fuel.

The timing couldn’t have been better. When the oil crisis hit in 1973, Japanese cars were already designed to use less fuel. This combination of fuel efficiency and lower emissions helped Japanese brands gain significant market share in the U.S.

Introduction of the Catalytic Converter

The catalytic converter became one of the most important pollution-control devices in automotive history. This technology converts harmful exhaust gases into less toxic substances before they leave the vehicle.

Japanese manufacturers embraced catalytic converter technology early and effectively. They integrated these devices into their manufacturing processes with remarkable efficiency, often at lower costs than their American competitors.

Honda particularly stood out by developing the CVCC (Compound Vortex Controlled Combustion) engine. This innovative design met emissions standards without requiring a catalytic converter, showcasing Japanese engineering prowess.

The success of these clean technologies helped Japanese companies make significant inroads into global markets during the 1970s, permanently changing the automotive landscape.

Competing in Global Markets

Japanese automakers developed strategic approaches to penetrate international markets during the 1970s. Their focus on quality, efficiency, and customer needs helped them gain significant ground against established manufacturers.

Entering the American Market

The 1970s marked a turning point when Japanese car brands like Honda, Toyota, and Nissan established a significant presence in the US market. Initially viewed as cheap alternatives to American cars, these companies quickly built a reputation for reliability and fuel efficiency.

The 1973 oil crisis provided perfect timing for Japanese entry. American consumers, facing high gas prices, turned to fuel-efficient Japanese models as practical alternatives to gas-guzzling domestic vehicles.

By the end of the decade, Japanese imports had grown from 17.7% to 28% of US car sales, a remarkable achievement in just ten years. This rapid growth demonstrated the market’s receptiveness to Japanese automotive design and engineering principles.

Toyota’s Corolla and Honda’s Civic became particularly popular models, offering American consumers affordable transportation with greater reliability than many domestic competitors.

Challenging Detroit’s Big Three

Japanese automakers directly challenged General Motors, Ford, and Chrysler (the Big Three) with a simple but effective strategy: better quality at competitive prices. While Detroit focused on large cars with high profit margins, Japanese companies targeted the compact and subcompact segments.

The Big Three initially dismissed Japanese cars, but consumer perception was shifting. Japanese vehicles were becoming the standard for quality, consistently topping Consumer Reports and JD Power ratings.

Detroit’s response was slow and inadequate. American manufacturers struggled to match Japanese production efficiency and quality control standards.

Toyota’s production system became a case study in manufacturing excellence, with principles later adopted globally. This efficiency allowed Japanese makers to maintain competitive pricing while investing in continuous improvement.

Global Expansion Strategies

Japanese automakers pursued a methodical global strategy beyond the American market. They established manufacturing facilities in key regions to overcome import restrictions and reduce shipping costs.

Toyota and Honda led the way with early international production facilities. This approach reduced political tension around imports while creating local jobs in target markets.

Technological innovation became a cornerstone of their global strategy. Japanese manufacturers invested heavily in R&D, developing advances in engine efficiency, manufacturing processes, and later, hybrid technology.

Marketing strategies emphasized reliability and value rather than luxury or performance. This approach resonated with middle-class consumers worldwide seeking practical transportation.

Japanese companies also built extensive dealer networks with strong service departments. This focus on after-sales support created lasting customer relationships and positive word-of-mouth that drove further sales growth.

Economic Turbulence and the Japanese Response

The 1970s brought unprecedented economic challenges that reshaped the global automotive landscape. Japanese automakers transformed these obstacles into opportunities through strategic planning and innovative engineering approaches.

OPEC Oil Crisis Response

When the 1973 oil crisis hit, gasoline prices soared and fuel shortages plagued American consumers. While Detroit struggled with its gas-guzzling models, Japanese manufacturers were perfectly positioned with their fuel-efficient vehicles.

Toyota, Honda, and Nissan had already been producing smaller, more economical cars due to Japan’s domestic resource limitations. Their vehicles averaged 30+ miles per gallon when most American cars struggled to reach 15 mpg. This focus on fuel efficiency became their key competitive advantage.

Japanese manufacturers quickly adjusted production to meet growing demand for economical vehicles. Their market share in the US jumped from under 10% to nearly 20% between 1970-1975. These fuel-efficient models appealed to cost-conscious consumers dealing with inflation and economic uncertainty.

Navigating the Global Recession

The mid-1970s global recession further tested automotive manufacturers worldwide. While American companies faced layoffs and production cuts, Japanese firms maintained momentum through strategic planning.

Japanese automakers implemented lean manufacturing techniques that reduced waste and improved efficiency. This approach allowed them to maintain competitive pricing despite economic pressures. Their just-in-time inventory systems minimized overhead costs during uncertain economic times.

Quality control became another differentiator. While American cars developed reputations for unreliability, Japanese vehicles gained favor for durability and build quality. By 1980, Japanese imports had grown to represent nearly 30% of US car sales.

Even as some Americans initially sneered at Japanese vehicles for being small and underpowered, consumer perceptions shifted as economic realities changed. Japanese manufacturers transformed the crisis into an opportunity to establish their long-term position in the global market.

Japan’s Influence on Global Car Manufacturing

Japan’s automotive revolution in the 1970s fundamentally transformed manufacturing practices worldwide. The methods pioneered by Japanese automakers established new standards for efficiency, quality, and innovation that competitors had to adopt to remain viable.

Management Techniques and Lean Manufacturing

Japanese car makers, especially Toyota, developed revolutionary management approaches that changed global manufacturing. The Toyota Production System introduced “lean manufacturing” principles that eliminated waste while improving quality.

Just-in-time inventory reduced storage costs and ensured fresh components. The kanban system created smooth workflows and prevented bottlenecks. Quality circles empowered workers to identify problems and suggest improvements.

Japan also pioneered robotics in vehicle manufacturing during the 1970s. This automation increased precision and consistency while reducing labor costs.

The kaizen philosophy of continuous improvement became essential to Japanese success. Every worker, from assembly line to executive suite, participated in finding better methods and solutions.

Impact on American and European Manufacturers

American giants like Ford and Chrysler initially dismissed Japanese cars as small, underpowered novelties. This miscalculation proved costly as fuel crises hit and consumer preferences shifted toward more efficient vehicles.

Japanese offerings featured better reliability, fuel efficiency, and value. This competitive edge forced American and European manufacturers to rethink their approaches.

Volkswagen and other European makers adapted more quickly than their American counterparts. They recognized the changing market and began implementing Japanese-inspired manufacturing techniques.

Many Western plants suffered closures as Japanese imports gained market share. This created tension that led to import quotas and eventually prompted Japanese companies to build manufacturing facilities in North America and Europe.

Western companies eventually adopted quality control systems, just-in-time inventory, and team-based problem-solving methods from their Japanese competitors.

Legacy and Continued Evolution

The transformation of car manufacturing extended beyond factories to establish new global standards for the entire industry. Japanese influence remains evident in modern automotive production worldwide.

Most car manufacturers now use some version of lean manufacturing techniques. The focus on eliminating waste while maximizing quality has become standard practice globally.

Japan’s emphasis on detail-oriented engineering continues to influence vehicle development. Their approach to incremental improvement rather than dramatic redesigns proved more sustainable long-term.

The hybrid organizational structure combining Western innovation with Japanese efficiency became a template for global manufacturing operations. This fusion approach helped companies adapt to changing market conditions.

Today’s automotive manufacturers continue refining these Japanese-inspired systems as they face new challenges like electrification, autonomous driving, and sustainable production methods.

Conclusion

Japan’s automotive revolution in the 1970s fundamentally changed global car manufacturing and consumer expectations. This transformation continues to influence industry standards and innovation approaches today.

Summarizing Japan’s Revolutionary Impact

The Japanese automotive invasion of the 1970s represented one of the most significant shifts in global manufacturing history. Japanese automakers grew from just 1.4% of U.S. market share in 1970 to becoming dominant players by decade’s end, reaching 28% of U.S. car sales.

This remarkable achievement stemmed from a focused strategy emphasizing quality, efficiency, and consumer needs. Japanese manufacturers transformed cars from unreliable luxuries into dependable necessities through innovative production systems and quality control.

What began as dismissed “cheap junk” evolved into vehicles that consistently topped Consumer Reports and JD Power ratings. The revolution forced Western automakers to reimagine their approaches and ultimately benefited consumers worldwide through better, more affordable vehicles.

Looking to the Future: Continuing Innovation

Japanese automakers continue pushing boundaries with the same principles that fueled their initial success. Their focus on fuel efficiency, reliability, and affordability positions them well for addressing 21st-century challenges like climate change and resource scarcity.

Today’s Japanese automotive innovation centers on:

- Electric vehicle development

- Autonomous driving technologies

- Hydrogen fuel cell advancement

- Smart manufacturing techniques

These efforts maintain Japan’s influential position in the global automotive landscape. While facing new competition from emerging markets and technology companies, Japanese manufacturers leverage their deep manufacturing expertise and quality-focused culture.

The principles that revolutionized car manufacturing in the 1970s remain relevant as the industry navigates increasingly complex technological and environmental challenges.

Frequently Asked Questions

The Japanese automotive revolution of the 1970s transformed global manufacturing standards, market expectations, and design priorities through several key innovations and market forces.

What manufacturing innovations led to the success of the Japanese auto industry in the 1970s?

Japanese automakers pioneered the implementation of lean manufacturing principles, most notably the Toyota Production System. This approach minimized waste while maximizing efficiency and quality.

Just-in-time inventory systems reduced storage costs and improved production flow by ensuring parts arrived exactly when needed on the assembly line.

Quality circles empowered workers to identify problems and suggest improvements, creating a culture of continuous improvement known as “kaizen” that dramatically reduced defects.

Automation was strategically implemented alongside human expertise, creating production lines that balanced efficiency with quality craftsmanship and attention to detail.

How did the advent of Japanese cars impact the automobile market in the United States during the 1970s?

Japanese vehicles dramatically shifted American consumer expectations about reliability and fuel efficiency. The oil crisis of the 1970s created perfect market conditions for fuel-efficient Japanese imports.

American manufacturers were forced to reconsider their focus on large, powerful vehicles as consumers flocked to smaller, more economical Japanese alternatives.

Initially, Japanese cars were viewed skeptically by some Americans who preferred larger vehicles, but perceptions shifted as reliability advantages became apparent.

Japanese brands steadily gained market share throughout the decade, establishing permanent footholds in what had previously been a domestic-dominated market.

What factors contributed to the popularity and ascent of Japanese cars in the 1970s?

Fuel efficiency, reliability, and affordability formed the cornerstone of Japanese automotive appeal during this era. These qualities perfectly addressed consumer needs during the energy crisis.

Japanese manufacturers excelled at detail-oriented engineering that prevented common mechanical failures plaguing American vehicles of the time.

Consistent quality control meant buyers could trust Japanese vehicles to perform as advertised with minimal maintenance issues.

Strategic pricing positioned Japanese imports as excellent value propositions that delivered better reliability at competitive price points compared to domestic options.

In what ways did Japanese automobile manufacturing principles influence global car production practices?

The Toyota Production System became a global manufacturing model that transformed how cars were built worldwide. American and European manufacturers began adopting lean principles to remain competitive.

Statistical quality control methods pioneered in Japanese factories spread throughout the global automotive industry.

Worker involvement in quality assurance became standard practice internationally, replacing the previous model of inspection after production.

The concept of continuous improvement processes revolutionized manufacturing across industries beyond automotive production.

How did the quality and design of Japanese cars compare to their American counterparts during their rise in the 1970s?

Japanese vehicles prioritized space efficiency and ergonomics while American cars often emphasized size and power. This fundamental design philosophy difference reflected different market priorities.

Japanese cars typically offered better fit and finish, with tighter panel gaps and more consistent assembly quality.

American vehicles of the era often suffered from quality control issues, including rust problems, electrical failures, and mechanical unreliability that Japanese manufacturers had largely eliminated.

Interior design in Japanese vehicles focused on driver comfort and intuitive controls, contrasting with sometimes flashier but less functional American interiors.

What role did Japanese car manufacturers play in the global shift toward more fuel-efficient vehicles during the 1970s?

The 1970s oil crisis created market demand that Japanese manufacturers were uniquely positioned to meet with their smaller, fuel-efficient models.

Japanese companies had already developed expertise in building smaller engines that maximized efficiency without sacrificing reliability.

Innovations like improved carburetors, more efficient transmissions, and weight reduction techniques helped Japanese vehicles achieve significantly better mileage.

This fuel efficiency focus eventually forced all global manufacturers to improve their vehicles’ economy, permanently shifting industry priorities away from the previous bigger-is-better philosophy.