Keeping your car’s suspension in good shape is key to both comfort and safety on the road. As your vehicle ages, shock absorbers gradually wear out, affecting how your car handles bumps and turns. Most experts recommend replacing shock absorbers every 50,000-100,000 miles, though this varies based on driving conditions and style.

You might not notice shock wear immediately because it happens slowly over time. Pay attention to warning signs like excessive bouncing after hitting bumps, unusual tire wear patterns, or fluid leaking from the shocks themselves. When your car starts having steering problems or takes longer to stop, these could also indicate your shocks need attention.

Regular maintenance checks can help catch shock absorber issues before they become dangerous. While the 50,000-mile mark is a good general guideline, drivers who frequently travel on rough roads or carry heavy loads may need replacements sooner. Investing in timely shock replacement not only improves ride quality but can also extend your vehicle’s overall lifespan.

Key Takeaways

- Shock absorbers typically need replacement every 50,000-100,000 miles depending on driving conditions and vehicle use.

- Warning signs include excessive bouncing, uneven tire wear, steering difficulties, and longer braking distances.

- Regular inspections help identify worn shocks before they compromise vehicle safety and performance.

Understanding Shock Absorbers

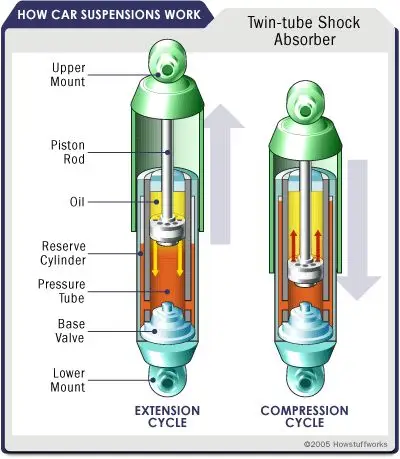

Shock absorbers are vital components that help control the movement of your vehicle’s suspension system. They work by converting kinetic energy from bumps and road vibrations into heat, allowing for a smoother and more controlled ride.

Purpose of Shock Absorbers

Shock absorbers do not actually support the vehicle’s weight—contrary to what many believe. Their primary job is to control the rate of movement in your suspension system. When you hit a bump, your springs compress and then expand, which would cause your car to bounce continuously without shock absorbers.

These components dampen oscillations by forcing oil through narrow passages, creating resistance. This resistance slows down spring movements, keeping your tires in contact with the road.

Good shock absorbers improve:

- Vehicle stability

- Handling precision

- Braking efficiency

- Tire wear patterns

- Overall ride comfort

Without functioning shock absorbers, your car would bounce excessively, making it difficult to control, especially during emergency maneuvers or when driving on rough roads.

Shock Absorbers vs. Struts

Though often mentioned together, shocks and struts are not identical components. Shock absorbers are standalone components that work alongside springs in the suspension system.

Struts, however, are structural components that incorporate both the shock absorber function and a spring seat. They form a crucial part of the vehicle’s suspension and steering systems.

Key differences include:

| Feature | Shock Absorbers | Struts |

|---|---|---|

| Structural role | No structural function | Integral structural component |

| Replacement complexity | Relatively simple | Requires alignment afterward |

| Cost | Generally less expensive | Usually more expensive |

| Location | Can be on any wheel | Typically on front wheels |

Most vehicles have either shocks or struts at each wheel, though some use a combination of both.

Role in Suspension Systems

Within the suspension system, shock absorbers work alongside springs, control arms, and other components to maintain vehicle stability. When functioning properly, they ensure the tires maintain optimal contact with the road surface.

The suspension system must balance two competing goals: passenger comfort and vehicle control. Shock absorbers play a critical role in this balance by controlling the rate at which weight transfers during acceleration, braking, and cornering.

They also help prevent excessive body roll when turning and nose-diving during braking. By controlling these movements, shock absorbers contribute significantly to vehicle safety, especially in emergency situations where maintaining control is critical.

Key Ride Control Parts

A complete suspension system contains several ride control parts that work together with shock absorbers:

Springs – Support the vehicle’s weight and absorb large impacts. Types include coil springs, leaf springs, and torsion bars.

Ball Joints – Allow the wheels to move up and down while turning left and right.

Control Arms – Connect the wheel assemblies to the vehicle frame, allowing vertical movement.

Sway Bars – Reduce body roll during cornering by transferring movement from one side of the vehicle to the other.

Bushings – Rubber or polyurethane components that isolate vibrations between moving suspension parts.

All these suspension components must work together properly. Failure in any one part can accelerate wear on others, including shock absorbers.

Common Signs You Need to Replace Shock Absorbers

Your vehicle’s shock absorbers play a critical role in maintaining ride comfort and safety. When they begin to fail, several telltale signs will alert you to potential problems before they become serious safety concerns.

Compromised Handling and Stability

When shock absorbers wear out, your vehicle’s handling becomes less predictable. You might notice the car drifting or swaying during turns, even at moderate speeds. This happens because worn shocks can’t properly control the vehicle’s weight transfer.

Another common indicator is excessive nose-diving during braking. If your car’s front end dips dramatically when you apply the brakes, this points to failing front shock absorbers.

Steering response may also become sluggish or unpredictable. When driving over bumps or potholes, you might feel like you’re about to lose control of your vehicle. This is particularly dangerous in emergency situations when quick steering adjustments are necessary.

Poor stability during windy conditions is another warning sign. If your car feels unusually affected by crosswinds or when passing large trucks, worn shock absorbers may be the culprit.

Noticeable Tire Wear Patterns

Failing shock absorbers often lead to uneven tire wear patterns. When shocks deteriorate, they can’t keep the tires firmly planted on the road surface, causing them to bounce and create scalloped or cupped wear patterns.

Look for patches of excessive wear across the tire tread. These spots occur when the tire repeatedly loses and regains contact with the road due to poor dampening from worn shocks.

Signs of shock-related tire wear:

- Cupped or scalloped patterns

- Uneven wear across the same tire

- Premature wear on all tires

- Bald spots developing in unusual patterns

This irregular wear not only compromises traction but also forces you to replace tires more frequently, increasing your maintenance costs significantly.

Persistent Bumpy Ride

Perhaps the most noticeable sign is a consistently bumpy or bouncy ride. If your vehicle continues bouncing after hitting a bump or pothole, your shocks are likely failing. A simple test is the “bounce test” – push down hard on each corner of your vehicle and release.

A vehicle with healthy shocks should rebound once and stop. If it bounces more than 5 times after going over a bump, replacement is necessary.

Fluid leaks around the shocks indicate seal failure. These appear as oily residue on the shock body. If you see wet oil dripping down the side, immediate replacement is required.

The ride quality degradation usually happens gradually, making it easy to overlook. Passengers might comment that the ride feels rougher than they remember, which can be a valuable clue.

Physical Symptoms of Failing Shock Absorbers

Shock absorbers show clear physical signs when they start to fail. These signs are often visible during routine inspections and can help vehicle owners identify problems before they lead to unsafe driving conditions.

Leaking Fluid or Oil

One of the most obvious signs of shock absorber failure is fluid leaking from the unit. Shock absorbers contain hydraulic fluid that helps them control the vehicle’s movement. When you see oil or fluid on the outside of the shock, it indicates the seal has failed.

This leakage appears as a wet, oily substance on the shock’s body. Fresh leaks look shiny and wet, while older leaks collect dust and appear darker. Even small leaks signal that the shock absorber is compromised.

As fluid escapes, the shock’s ability to dampen movement decreases. The vehicle may begin to bounce excessively, especially on rough roads. This not only creates an uncomfortable ride but can also reduce tire contact with the road.

Always check for leaks after driving on rough terrain or hitting potholes, as these conditions can damage seals and accelerate fluid loss.

Visible Damage or Corrosion

Physical damage to suspension components often indicates it’s time for replacement. Inspect shocks for dents, bends, or corrosion that might affect performance.

Shock absorbers can suffer damage from road debris, accidents, or even severe potholes. Look for bent mounting brackets, damaged bushings, or dented shock bodies. These issues prevent proper function and compromise safety.

Rust and corrosion are particularly problematic for shock absorbers. While light surface rust may be normal, extensive corrosion can weaken the metal and lead to failure. Pay special attention to:

- Mounting points where the shock connects to the vehicle

- Shock body surfaces

- Piston rods (should be smooth and unblemished)

- Bushings and rubber mounts (check for cracks or deterioration)

Regular inspections every 6-12 months can help identify these issues before they lead to complete failure or unsafe driving conditions.

Performance and Safety Impacts

Worn shock absorbers significantly compromise vehicle safety systems and driving dynamics. The degradation occurs gradually, often going unnoticed until reaching dangerous levels that affect critical vehicle operations.

Reduced Crash-Avoidance System Effectiveness

Modern vehicles rely on properly functioning suspension components for crash-avoidance systems to work effectively. When shock absorbers wear out, they allow excessive body movement that interferes with these safety systems. Anti-lock brakes and electronic stability control become less reliable because they depend on consistent tire-to-road contact.

Vehicle sensors that feed data to crash-avoidance systems may receive inconsistent information when the car bounces excessively. This compromises the timing and effectiveness of automatic emergency braking and collision warnings.

Studies show that vehicles with worn shock absorbers experience up to 15% reduction in the effectiveness of lane departure warnings and automatic emergency braking systems. This decline in performance creates a dangerous gap in safety protection that most drivers don’t realize exists.

Increase in Stopping Distances

Deteriorated shock absorbers directly impact a vehicle’s ability to stop quickly. When braking with worn shocks, tires lose consistent contact with the road surface, creating a dangerous bouncing effect called “wheel hop.”

Testing has demonstrated that cars with worn shock absorbers can require up to 20% more distance to stop compared to vehicles with properly functioning components. This increased stopping distance becomes especially dangerous in emergency situations.

The problem worsens in adverse weather conditions. On wet or slippery roads, worn shock absorbers allow more weight transfer during braking, reducing overall grip and stability.

Even on dry roads, the decreased handling precision means drivers must brake earlier and more gradually to maintain control. This safety margin reduction happens so subtly that most drivers adjust their driving style without realizing their vehicle’s capabilities have diminished.

Mileage and Service Life Expectations

Shock absorbers have predictable lifespans that vary based on several key factors. Most manufacturers design these crucial suspension components with specific service intervals in mind, though real-world conditions often determine their actual longevity.

Average Lifespan of OEM Shocks

Most original shocks installed by manufacturers typically last between 50,000 and 100,000 miles under normal driving conditions. Many vehicle owners don’t realize that shock absorbers wear out gradually, making the degradation difficult to notice day-to-day.

Industry standards suggest replacing shocks around the 10-year or 100,000-mile mark. However, this can vary by vehicle make and model.

Regular maintenance inspections should begin around 50,000 miles, which is when many shocks start showing early signs of wear. Some premium vehicles may have longer-lasting components.

Replacing worn shocks at the recommended intervals can extend vehicle life expectancy and maintain optimal performance as the vehicle ages.

Impact of Road and Driving Conditions

Rough roads significantly reduce shock absorber lifespan, sometimes by 50% or more compared to ideal conditions. Frequent driving on unpaved roads, over potholes, or speed bumps accelerates wear on these components.

Aggressive driving habits such as:

- Rapid acceleration and braking

- Taking corners at high speeds

- Carrying heavy loads regularly

These behaviors can cause shocks to wear out closer to the 50,000-mile mark rather than reaching their full potential lifespan.

Climate also plays a role in shock longevity. Extreme temperatures and road salt in winter conditions can lead to faster deterioration of shock components.

Vehicles used primarily for city driving with frequent stops may experience different wear patterns than those used mostly for highway driving.

Routine Inspection and Maintenance Guidelines

Regular assessment of shock absorbers is essential for vehicle safety and performance. Proper timing of inspections helps catch issues before they lead to dangerous driving conditions or costly repairs.

Recommended Inspection Intervals

Most vehicle manufacturers suggest having shocks and struts inspected annually or whenever the vehicle undergoes tire, brake, or alignment service. This frequency ensures potential problems are identified early.

Shock absorbers typically need replacement every 50,000-100,000 miles, though this varies based on driving habits and road conditions. Aggressive driving or frequently traveling on rough roads will accelerate wear.

Drivers should perform basic visual checks between professional inspections. Signs to look for include:

- Fluid leaking from the shock body

- Visible damage or dents

- Excessive bouncing after hitting bumps

- Uneven tire wear patterns

After operation, properly functioning shocks should feel warm to the touch. Cold shocks may indicate a malfunction requiring replacement.

Professional Shock and Strut Service

Professional mechanics use specialized equipment to thoroughly evaluate suspension components. During a complete inspection, technicians will:

- Perform a bounce test to check dampening capabilities

- Examine mounts and bushings for wear

- Check for leaking hydraulic fluid

- Inspect for physical damage or corrosion

Many repair shops, including specialty suspension services, offer free inspection programs. These evaluations help determine if replacement is necessary based on manufacturer guidelines.

When replacement is needed, professional installation ensures proper torque specifications and alignment. Most services include a post-installation road test to confirm the new shocks perform correctly.

Shops typically recommend replacing shocks in pairs (front or rear) even if only one shows significant wear, maintaining balanced handling characteristics.

Choosing the Right Time to Replace Shocks

Knowing when to replace your vehicle’s shock absorbers is crucial for maintaining safety and comfort on the road. Most vehicles need shock replacement every 50,000-100,000 miles, but driving habits and road conditions can significantly affect this timeline.

DIY Assessment Tips

Drivers can perform several simple tests to determine if shock replacement is needed. A bounce test involves pushing down firmly on each corner of the vehicle and releasing. If the car bounces more than 1-2 times, the shocks may be worn.

Visual inspections are equally important. Look for:

- Leaking fluid on the shock body

- Dents or damage to the shock absorber

- Worn bushings or mounts

- Uneven tire wear patterns

Pay attention to driving symptoms while on the road. Excessive nose-diving during braking, continued bouncing after hitting bumps, or vehicle swaying during turns often indicate failing shocks.

Unusual noises like knocking or clunking when driving over bumps also suggest shock absorber problems. These sounds typically worsen as the components deteriorate further.

Consulting Automotive Professionals

Professional mechanics can provide definitive assessments about shock absorber condition during regular maintenance visits. Most experts recommend having shocks and struts checked every 12,000-15,000 miles as part of routine service.

Mechanics use specialized equipment to test shock performance beyond what’s visible to the untrained eye. They can measure ride height, perform dynamic suspension tests, and identify early warning signs of failure.

Some service centers offer free suspension checks. These evaluations can help drivers make informed decisions about replacement timing before problems become severe or dangerous.

Second opinions are valuable when significant repair costs are involved. Different shops may have varying perspectives on whether immediate replacement is necessary or if the components have remaining service life.

Remember that driving with worn shocks affects more than comfort—it impacts braking distance, handling, and tire life, making timely replacement an important safety consideration.

Frequently Asked Questions

Shock absorbers play a crucial role in vehicle performance and safety. Here are answers to common questions about maintaining and replacing these important components.

How can I tell if my shock absorbers need to be replaced?

You can perform a simple bounce test by pushing down hard on each corner of your vehicle and releasing. If the car bounces more than once or twice, your shocks might be worn out.

Look for visible leaking fluid or physical damage on the shock absorber body. These are clear signs replacement is needed.

Pay attention to how your car handles. Excessive bouncing, swaying during turns, or nose-diving when braking indicates worn shocks.

What are the common symptoms of worn-out struts?

Unusual noises like knocking or clunking when driving over bumps often indicate strut problems. These sounds typically get worse over time.

Poor handling is a key symptom. Your vehicle may drift or pull to one side during turns or feel unstable at highway speeds.

Uneven or premature tire wear, especially in a cupping pattern, can signal strut issues. Check your tires regularly for abnormal wear patterns.

At what mileage should one typically consider replacing their vehicle’s struts?

Most manufacturers recommend replacing struts every 50,000 to 100,000 miles. The wide range depends on driving conditions and habits.

Drivers who frequently travel on rough roads or carry heavy loads may need replacements closer to the 50,000-mile mark. Regular driving on smooth highways might extend their life.

Some mechanics suggest having struts inspected around the 50,000-mile point to assess their condition, even if they’re not showing obvious signs of wear.

What is the estimated cost range for replacing front struts?

Front strut replacement typically costs between $450 and $900 for a pair, including parts and labor. Luxury vehicles often fall at the higher end of this range.

Some shops offer complete strut assembly replacements (including springs and mounts), which cost more upfront but save on labor.

Getting multiple quotes from different repair shops can help find reasonable pricing for your specific vehicle make and model.

What is the difference between shocks and struts in terms of functionality and vehicle handling?

Shocks and struts both dampen spring oscillation, but struts are also a structural component of the suspension system. They help support the vehicle’s weight and maintain alignment.

Vehicles have either shocks or struts at each wheel, never both. Most modern cars use struts in the front and shocks in the rear.

Struts affect alignment angles directly, so replacement usually requires a wheel alignment afterward, while shock replacement typically doesn’t.

After installing new struts, what kind of ride quality should I expect?

New struts typically provide a firmer, more controlled ride compared to worn components. The vehicle should feel more stable when cornering and braking.

You might notice the ride feels slightly stiffer initially. This is normal and indicates the new struts are properly damping the suspension movement.

After installation, allow a break-in period of about 300-500 miles for the struts to fully settle. During this time, avoid aggressive driving or extreme road conditions when possible.