Driving with broken or dim lights isn’t just dangerous—it could also result in a failed inspection or ticket. Car lights are essential safety features that help you see the road and allow other drivers to see you. Regular inspection and timely replacement of your car’s lights can prevent accidents and ensure you meet legal requirements for road safety.

You don’t need to be a mechanic to check your car lights. With basic tools and a little knowledge, you can inspect your vehicle’s lighting system and even replace burnt-out bulbs yourself. From headlights to tail lights, knowing how to maintain these components can save you money and keep you safe on the road.

Key Takeaways

- Regular light bulb inspections improve visibility and safety while helping you avoid tickets and failed vehicle inspections.

- Most car light bulbs can be replaced at home with basic tools, though some vehicles require special steps or professional assistance.

- When replacing lights, always ensure new bulbs are DOT approved to meet legal requirements and avoid inspection failures.

Understanding Different Types of Car Lights

Car lights serve different purposes and work in specific ways. Modern vehicles come equipped with several types of lights, each designed for unique driving conditions and safety requirements.

Headlights

Headlights are the primary forward-facing lights that illuminate the road ahead when driving in darkness or poor visibility. There are three main types of headlight bulbs: halogen, HID (High-Intensity Discharge) xenon, and LED.

Halogen headlights are the most common and affordable option. They use a filament that glows when electricity passes through it, producing a yellowish light. These typically last 500-1,000 hours.

HID xenon lights create a brighter, whiter light by using xenon gas instead of a filament. They consume less energy than halogens and last up to 2,000 hours, but cost more to replace.

LED headlights are the newest technology. They produce bright, clean light while using minimal energy. LEDs can last up to 20,000 hours but come with a higher initial cost.

Fog Lights

Fog lights are mounted low on the vehicle, typically below the headlights. Their specific design helps drivers see the road in foggy, misty, or snowy conditions.

These lights produce a wide, flat beam pattern that illuminates the road surface without reflecting back off fog or precipitation. The low positioning prevents light from bouncing off moisture in the air.

Fog lights should only be used in conditions of reduced visibility, not as an alternative to headlights. Many cars feature yellow fog lights, as this color penetrates fog better than white light.

Most modern vehicles include a dedicated fog light symbol on the dashboard. This appears as a light with lines pointing downward or to the side, indicating the light’s downward trajectory.

Tail Lights

Tail lights are red lights at the rear of the vehicle that activate automatically when headlights are on. They make the car visible to drivers behind, especially in darkness or poor weather.

Modern tail lights typically use LED technology for greater brightness and longevity. This improves safety by ensuring other drivers can see the vehicle clearly from a distance.

Inspecting tail lights requires help from another person or using a mirror to check their operation while pressing the brake pedal. Alternatively, backing up toward a reflective surface like a garage door can help verify they’re working.

Tail light assemblies often contain multiple functions in one unit, including brake lights, turn signals, and reverse lights. Each serves a specific purpose for communicating the driver’s intentions to others on the road.

Signs Your Car Lights Need Inspection or Replacement

Regular inspection of your car lights can prevent driving hazards and tickets. Recognizing early warning signs will help you address problems before they become dangerous or expensive to fix.

Dimming or Flickering Lights

Dimming headlights are a clear signal that something isn’t right with your vehicle’s lighting system. When your lights appear less bright than usual or you have trouble seeing on the road, it’s time for an inspection.

Flickering lights often indicate electrical issues or a bulb that’s about to fail. This symptom shouldn’t be ignored as it can worsen suddenly, leaving you without proper illumination when you need it most.

Uneven brightness between headlights suggests one bulb is newer or one is failing. If one headlight appears yellowed or dim compared to the other, replacement is necessary.

Sometimes dimming occurs when switching between high and low beams. If high beams work while low beams don’t respond properly, this might indicate electrical problems rather than just a bulb issue.

Warning Indicators on Dashboard

Most modern vehicles include dashboard warning lights specifically for headlight or taillight failures. When these indicators illuminate, it means the car’s computer system has detected a problem.

Some cars emit unusual beeping sounds when lights malfunction. These audible warnings serve as alerts that something needs attention in your lighting system.

During startup diagnostics, many vehicles perform a quick check of all lights. If you notice an error message or warning light during this process, it’s time to inspect your lights.

For vehicles with automatic headlights, erratic behavior like lights turning on and off unexpectedly can indicate a sensor issue or electrical problem that requires professional diagnosis.

Physical Damage or Discoloration

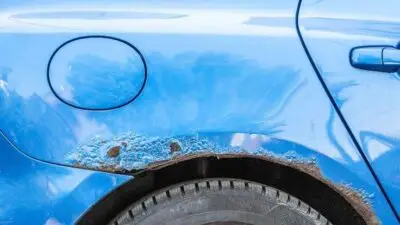

Visible cracks or moisture inside headlight assemblies can compromise light output and electrical safety. Water intrusion often leads to shorting and premature bulb failure.

Yellowed or foggy lenses significantly reduce light output. This discoloration occurs from UV exposure over time and can cut visibility by 50% or more, creating dangerous driving conditions.

Routine visual inspections can reveal problems before they affect your driving. Walking around your vehicle to check all lights should be part of your regular maintenance routine.

Aftermarket lights might need special attention. Some vehicles fail inspections due to non-DOT approved aftermarket lights. If you’ve modified your vehicle’s lighting, ensure all components meet legal requirements.

Pre-Inspection Preparation

Before checking or replacing your vehicle’s lights, proper preparation ensures safety and efficiency. Having the right tools and taking safety precautions will make the process smoother and help avoid common mistakes.

Gathering the Required Tools

Start by collecting all necessary tools for light inspection and replacement. You’ll need a clean cloth for wiping lenses, a screwdriver set (both flathead and Phillips), and replacement bulbs specific to your vehicle model.

Many vehicles require different bulb types for headlights, taillights, and turn signals. Check your owner’s manual to identify the correct bulb specifications before purchasing replacements.

Additional helpful tools include:

- Disposable gloves (to avoid touching bulb glass)

- Flashlight

- Multimeter (to check electrical connections)

- Small mirror (for viewing hard-to-see connections)

Consider purchasing bulbs ahead of time if any are currently failing. This saves time and ensures you can complete the replacement immediately after inspection.

Ensuring Safety Precautions

Safety should be your top priority when working with vehicle electrical systems. Always work on a cool engine to prevent burns, as headlight areas can become extremely hot during operation.

Disconnect the car battery before replacing lights to avoid electrical shock or short circuits. The negative terminal should be disconnected first. Park on a flat, stable surface with the parking brake engaged.

Wear gloves when handling new bulbs, especially halogen ones. The oils from your skin can create hot spots on bulbs, causing them to fail prematurely. If you accidentally touch a bulb, clean it with alcohol before installation.

Be aware of any dashboard warning lights that might indicate electrical issues before beginning your inspection. These could signal problems beyond simple bulb replacement.

How to Inspect Car Lights

Regular inspection of your car lights ensures safety on the road and helps avoid tickets during vehicle inspections. Proper functioning headlights, taillights, brake lights, and turn signals are essential for visibility and communication with other drivers.

Visual Examination of Lenses and Housings

Start by examining all light lenses and housings for damage. Look for cracks, condensation, or yellowing that might reduce light output. Check for dirt and debris that could dim your lights—clean lenses provide maximum visibility.

Make sure headlight housings are securely attached to the vehicle. Loose housings can cause misaligned beams, reducing your ability to see at night.

Inspect for water inside light assemblies. Water intrusion indicates a seal failure that needs immediate attention to prevent electrical damage.

Check LED lights with clear lenses to ensure they’re of an approved type to pass inspection requirements in your area.

Examine sidemarker lights, which are often overlooked. These are typically accessed under the front fender and are important for side visibility.

Testing Operation and Light Output

Test all lights systematically using the headlight switch in each position. You’ll need a helper or reflective surface to check lights at the rear of the vehicle.

Verify that both low and high beams work correctly. High beams should illuminate much farther down the road than low beams.

Check brake lights by pressing the brake pedal while someone observes from behind. Both brake lights should illuminate equally bright.

Test turn signals front and rear. They should blink at a consistent rate—too fast usually indicates a burned-out bulb.

Check hazard lights by activating the hazard button. All four corner lights should flash simultaneously.

Assess light output at night. Dim headlights might require bulb replacement or lens restoration. Proper lighting helps you spot obstacles to avoid while driving in low-light conditions.

Replacing Headlights

Replacing your car headlights is a simple task that most drivers can handle without professional help. The process typically involves accessing the headlight assembly, removing the old bulb, and installing a new one with proper handling techniques.

Removing the Bulb Assembly

First, ensure your vehicle is turned off and the keys are removed from the ignition for safety reasons. Open the hood and locate the headlight housing, which usually sits at the front of the engine compartment.

Most modern vehicles provide access to headlights from the engine compartment. Look for a bulb holder with electrical wires connected to it at the back of the headlight.

To remove the assembly, you’ll need to:

- Disconnect the power connector by pressing the plastic clip or tab

- Remove any dust covers protecting the bulb

- Release the retaining clip, spring, or screw holding the bulb in place

Different vehicles have various access methods, so consult your owner’s manual if you’re unsure about your specific model.

Installing New Headlight Bulbs

When handling new halogen headlight bulbs, avoid touching the glass with bare fingers. The oil from skin can create hot spots that shorten bulb life. Use gloves or a clean cloth to handle the new bulb.

Match the new bulb to your vehicle’s specifications. The old bulb’s part number can guide your purchase, or consult your owner’s manual for the correct bulb type.

Installation steps:

- Insert the new bulb into the socket, aligning it properly

- Secure the bulb with the retaining clip or mechanism

- Reattach the power connector until it clicks

- Replace any protective covers

After installation, turn on your headlights to verify they work properly. If a bulb doesn’t light up, check the connections and ensure it’s properly seated. Jiffy Lube and other service centers can help if you encounter difficulties.

Replacing Fog Lights

Fog lights are an essential safety feature that improve visibility in poor weather conditions. When they stop working, replacing them promptly ensures your vehicle remains safe and compliant with inspection requirements.

Accessing the Fog Light Housing

Most fog lights are located in the lower part of the front bumper. To access them, you’ll need to check if you can reach them from underneath the vehicle or if you need to remove any covers.

For many cars, you can reach behind the bumper without removing any parts. Some vehicles require you to remove fixtures from under the front fender by turning them counterclockwise.

If access is difficult, check your owner’s manual for specific instructions. Some models might require partial removal of the bumper or wheel well liners.

Tools needed:

- Screwdriver (flathead or Phillips)

- Work gloves

- Replacement bulb (correct type for your vehicle)

- Flashlight

Swapping Fog Light Bulbs

Before starting, ensure the vehicle is turned off and the lights have cooled down. Safety should always be your priority when replacing any vehicle lights.

First, disconnect the wiring harness from the back of the fog light. This usually involves pressing a tab or clip and gently pulling it free.

Next, remove the old bulb. In most cases, this requires turning the bulb housing counterclockwise and pulling it straight out. Be careful not to touch the glass of the new bulb with bare fingers, as oils from your skin can cause premature failure.

Install the new bulb by aligning it properly and turning it clockwise until it locks into place. Reconnect the wiring harness and test the lights before finalizing the installation.

If your vehicle fails inspection due to fog light issues, you can temporarily remove the fog light fixtures to pass, then reinstall them afterward if desired.

Replacing Tail Lights

Tail lights are crucial safety features that alert other drivers to your presence and intentions on the road. When these lights fail, replacing them promptly can prevent accidents and traffic tickets.

Removing the Tail Light Assembly

Most tail light assemblies are secured with screws or bolts accessible from the trunk or rear area of the vehicle. First, turn off your engine and open the trunk or hatch. Locate the fasteners holding the tail light assembly in place. These are typically accessible from inside the trunk and may include thumbscrews or standard screws.

Remove these fasteners carefully and store them in a safe place. Some vehicles have plastic panels or carpet that need to be pulled back to access the mounting screws. Pull the tail light assembly straight back from the vehicle body, being careful not to force it.

The assembly should detach with gentle pressure. Disconnect the wiring harness by pressing the tab on the connector and pulling it apart. Inspect the connections for corrosion or damage while you have them apart.

Installing Replacement Tail Lights

Before installing the new tail light, compare it to the old one to ensure it’s the correct replacement. Check the bulb type and alignment before proceeding.

Connect the wiring harness to the new tail light assembly. You should hear a click when it’s properly seated. Test the lights before fully installing the assembly by turning on the headlights, pressing the brake pedal, and activating the turn signals.

Position the new assembly carefully, aligning it with the mounting holes in the vehicle’s body. Gently push it into place until it sits flush with the body.

Reinsert and tighten all fasteners, being careful not to overtighten as this can crack the plastic housing. Replace any interior panels or carpet that were moved. Close the trunk and verify all lights are working properly by walking around the vehicle with the lights on.

Vehicle-Specific Tips for Popular Car Brands

Different car manufacturers design their lighting systems with unique access methods and bulb types. The right approach varies significantly between domestic and import brands.

Domestic Brands: Buick, Chevrolet, Cadillac, Chrysler, Dodge, Ford, GMC, Lincoln, Mercury, Pontiac, Saturn, Oldsmobile

General Motors vehicles (Buick, Cadillac, Chevrolet, GMC, Pontiac, Saturn, Oldsmobile) typically allow headlight access from the engine compartment. Many Chevy models require removing the air intake assembly first. Buick and Cadillac often use sealed beam units in older models.

Ford and Lincoln vehicles usually have a retaining ring that twists counterclockwise. Mercury models follow similar designs. On most Ford F-150s, there’s a specific access panel behind the headlight assembly.

Chrysler, Dodge cars generally need the battery removed for driver-side headlight access. Newer models use push-and-turn mechanisms for bulb removal. Some Dodge Ram trucks require partial bumper removal for proper access.

Import Brands: Honda, Infiniti, Lexus, Mazda, Nissan, Porsche, Toyota, Jeep

Japanese brands (Honda, Toyota, Nissan, Mazda) often use plastic covers requiring a quarter-turn to access headlights. Honda Civics and Accords have rubber boots protecting the bulb connections. Toyota Camrys need removal of the air filter housing for certain headlight replacements.

Luxury imports like Lexus and Infiniti often require removal of the entire headlight assembly. Porsche models typically need specialized tools for proper access.

Jeep Wranglers feature easily accessible headlights with a simple ring retainer, while Cherokee models might require partial bumper removal. Grand Cherokees have a special access panel behind the headlight for bulb replacement.

Many newer models across all brands use LED lighting that requires professional replacement of entire units rather than individual bulbs.

Maintenance and Troubleshooting Tips

Regular car light maintenance prevents breakdowns and ensures optimal visibility while driving. Simple steps like cleaning and inspection can extend the life of your lights and help you identify problems before they become serious.

Preventing Future Issues

Clean your headlights regularly to maintain visibility. Use a gentle car-safe cleanser or a solution of vinegar and baking soda to remove dirt and grime that can reduce brightness.

Check all vehicle lights during your regular walk-around inspections. This simple habit can catch problems early.

Verify headlight alignment periodically. Misaligned headlights reduce visibility and can blind oncoming drivers.

Replace bulbs in pairs, even if only one has failed. This ensures even brightness and saves time since the second bulb is likely to fail soon.

Apply a UV protectant to plastic headlight covers to prevent yellowing and fogging. This extends their life and maintains brightness.

Identifying and Solving Electrical Problems

When troubleshooting dim lights, start with the basics. Always check the car’s light switch and dimmer settings before assuming there’s a serious problem.

Common Electrical Issues:

- Blown fuses (check your owner’s manual for fuse box locations)

- Corroded connections

- Damaged wiring

- Faulty relays or switches

Test your battery and alternator if multiple lights are dim. Electrical system problems often affect all lights simultaneously.

Use a multimeter to check for proper voltage at light connections if replacing bulbs doesn’t solve the issue. Normal readings should be close to battery voltage (12-14 volts).

Look for water inside light housings, which indicates seal failures. This requires replacement or resealing to prevent electrical shorts.

Legal and Safety Considerations for Replacing Car Lights

Proper car lighting is not just a matter of visibility but also regulated by law to ensure road safety. Different areas have specific requirements for headlights, taillights, and turn signals that drivers must follow to avoid fines and maintain safety.

Regulations on Light Types and Brightness

Car lighting regulations vary by country and state, but most have strict rules about light color and brightness. Headlights must typically be white or yellow, while taillights must be red. Most jurisdictions prohibit blue headlights, which are often confused with emergency vehicles.

Many areas require vehicles to have working headlights, taillights, and turn signals at all times. If one light fails, you should replace both to ensure consistent brightness and color.

HID (High-Intensity Discharge) and LED headlights must be properly installed in compatible housings. Aftermarket kits may be illegal if they exceed brightness limits or cause glare for other drivers.

DOT (Department of Transportation) approval is required for all replacement bulbs in the United States. Look for the “DOT” marking on packaging to ensure compliance with federal standards.

Ensuring Proper Alignment and Visibility

Headlight alignment is critical for safety and legal compliance. Improperly aimed headlights can blind oncoming drivers or provide inadequate road illumination. After replacing headlights, check and adjust their aim following your vehicle’s specifications.

To test alignment, park your car 25 feet from a wall in a dark area. The headlight beams should be at the same height and properly centered. Most vehicles have adjustment screws to correct the positioning.

When inspecting your vehicle lighting, check for cloudy or yellowed headlight lenses which can reduce visibility. Many states require headlights to be visible from at least 500 feet away.

Safety tips when replacing lights:

- Disconnect the battery before working on electrical components

- Wear gloves when handling new bulbs to prevent oils from your skin damaging them

- Allow hot bulbs to cool before replacement

- Test all lights after installation to ensure proper function

Regular maintenance of your car’s lighting system not only keeps you legal but significantly improves night driving safety.

When to Seek Professional Help

While many car light replacements can be handled by car owners, certain situations require professional expertise. Modern vehicles often have complex lighting systems that may be difficult to access or diagnose properly without specialized tools and knowledge.

Complex Electrical Systems

When your car experiences multiple light failures at once, this often indicates a deeper electrical issue rather than simple burnt-out bulbs. Problems with fuses, wiring harnesses, or the car’s central electrical system require professional diagnosis.

If you replace a bulb multiple times within a short period, this suggests an underlying electrical problem. A trained mechanic can test your vehicle’s charging system and voltage regulator.

Cars with integrated light assemblies that don’t allow individual bulb replacement also need professional service. Some modern vehicles require partial disassembly of front components to access headlight assemblies.

Professional auto technicians have specialized tools to diagnose intermittent lighting issues that might elude DIY troubleshooting. Many auto shops offer light inspection services that can pinpoint problems beyond just the bulbs themselves.

Advanced Lighting Technologies

Modern vehicles increasingly use LED and HID (High-Intensity Discharge) lighting systems that operate differently from traditional halogen bulbs. These systems often include control modules and ballasts that require proper diagnosis when malfunctioning.

Adaptive headlight systems that turn with steering input contain sensors and motors that need specialized diagnostic equipment if they malfunction. Improper installation of aftermarket lighting can lead to inspection failures or electrical problems that professionals can address correctly.

Some advanced lighting technologies operate at high voltages that pose safety risks to untrained individuals. HID systems, for instance, can produce several thousand volts during operation.

Vehicles with factory-installed LED lighting strips or accent lighting typically need professional service when these elements fail. These components are often integrated into larger assemblies that require specialized knowledge to repair properly.

Frequently Asked Questions

Car owners often have specific questions about light inspection and replacement that can help them maintain safety and comply with regulations. These answers address common concerns about costs, bulb types, and inspection procedures.

What is the typical cost to replace a car’s headlight bulb?

The cost to replace a headlight bulb typically ranges from $15 to $100 depending on your vehicle make and model. Basic halogen bulbs are the least expensive option, usually between $15-$30 per bulb.

High-intensity discharge (HID) and LED replacement bulbs cost more, often between $50-$100 each. Some luxury vehicles require special ordering or dealer installation, which adds to the cost.

Labor costs at auto shops generally run $15-$45 if you don’t replace the bulbs yourself. Many auto parts stores will install new bulbs for free if you purchase them at their location.

Can I change the bulbs in my car’s headlights to LEDs, and how?

Yes, you can upgrade to LED bulbs in most vehicles, but there are important considerations. First, check if LED conversions are legal in your state, as some require headlights to match original equipment specifications.

To change to LEDs, purchase conversion kits that match your vehicle’s bulb size (like H11, 9005, or H7). These kits typically include the LED bulbs, drivers, and sometimes adapters.

Installation involves accessing the headlight assembly, disconnecting the old bulb, connecting the LED and its driver, and securing everything in place. Some vehicles may need additional modifications to accommodate the different size and cooling requirements of LED bulbs.

What is the process for inspecting car lights before replacement?

To properly inspect your car lights, start by turning on all lights and walking around your vehicle to visually check each one. Look for dim lights, inconsistent color, or bulbs that don’t work at all.

Pay attention to flickering lights or those that only work intermittently, as these indicate imminent failure. Also check for moisture inside light housings, which can cause electrical issues.

For headlights, park facing a wall at night to check the brightness and alignment. Both headlights should have similar brightness and color temperature. Uneven lighting suggests one bulb may need replacement.

Which automotive service providers offer headlight bulb replacement services?

Quick service centers like Jiffy Lube offer light bulb inspection and replacement as part of their regular services. These shops can typically replace most types of exterior vehicle lights.

Most auto parts retailers including AutoZone, O’Reilly Auto Parts, and Advance Auto Parts offer free bulb installation when you purchase bulbs from their stores. This is a convenient option for straightforward replacements.

Dealerships and independent mechanic shops also provide light replacement services. While they charge labor costs, they’re better equipped to handle complex light assemblies found in newer vehicles.

How often should car light bulbs be inspected and replaced?

Car light bulbs should be inspected monthly as part of regular vehicle maintenance. A quick walk-around to check all exterior lights takes only a minute and can identify problems early.

Most halogen headlight bulbs last 500-1,000 hours of use, which translates to about 1-3 years for average drivers. HID bulbs typically last 2,000-3,000 hours, while LED bulbs can last 30,000 hours or more.

It’s wise to replace bulbs showing signs of age before they fail completely. Dimming, inconsistent color, or flickering are clear indicators that replacement is needed soon.

Are there any legal requirements for tail light bulb brightness or color?

Yes, tail lights must be red in color according to federal regulations in the United States. Most states require tail lights to be visible from at least 500-1,000 feet away at night.

Brake lights must be brighter than regular tail lights and also red in color. Turn signals can be either red or amber at the rear, though amber is more common and provides better visibility.

All exterior lights must work properly to pass state vehicle inspections. Laws prohibit modification that substantially changes light color or intensity from manufacturer specifications, so avoid extremely bright LED replacements that could blind other drivers.