Motorcycles have changed dramatically since their early days, and one of the biggest improvements has come from better aerodynamics. Early motorcycles had simple, boxy shapes that created a lot of wind resistance, but as engineers learned more about airflow, designs became sleeker and more efficient, leading to faster speeds and better fuel economy. The evolution from basic frames to today’s wind-tunnel-tested machines shows how important air resistance became to motorcycle performance.

The shift happened gradually over decades. Manufacturers started paying attention to how air moved around bikes in the mid-1900s. They added fairings, changed body shapes, and tested different designs to see what worked best. These changes didn’t just make bikes look cooler—they actually made them faster and easier to ride at high speeds.

Today’s motorcycles benefit from advanced computer testing and years of research. Designers can now predict how air will flow around every curve and surface before building a single prototype. This science-based approach has created bikes that slice through wind with minimal resistance, giving riders better performance and fuel efficiency than ever before.

Key Takeaways

- Motorcycle aerodynamics progressed from simple shapes to streamlined designs through decades of testing and engineering improvements

- Wind tunnel testing and computer simulations revolutionized how manufacturers create fairings and bodywork to reduce drag

- Better aerodynamics led to significant gains in speed, stability, and fuel efficiency for both racing and street motorcycles

Fundamentals of Motorcycle Aerodynamics

Motorcycle aerodynamics centers on how air moves around a bike and rider, creating forces that affect speed, fuel use, and control. The interaction between airflow, drag, and downforce determines how well a motorcycle performs on the road.

Principles of Airflow and Drag

Air flows around a motorcycle in patterns that create resistance. When a bike moves forward, it pushes air out of the way. This creates drag, which is the force that slows the motorcycle down.

Drag increases with speed. At higher speeds, air resistance grows much faster than the speed itself. A motorcycle traveling at 60 mph faces four times more drag than one going 30 mph.

Two main types of drag affect motorcycles:

- Pressure drag occurs when air can’t flow smoothly around the bike’s shape

- Friction drag happens when air rubs against the motorcycle’s surface

The rider creates most of the drag on a motorcycle. The human body has a blocky shape that disrupts airflow. This is why riders tuck in behind windshields or fairings to reduce their wind resistance.

Streamlined shapes help air flow more smoothly around the motorcycle. Rounded edges and gradual curves prevent turbulence, which is chaotic air movement that increases drag.

Impact of Wind Resistance

Wind resistance directly affects a motorcycle’s performance and fuel consumption. The engine must work harder to overcome drag at higher speeds, burning more fuel in the process.

For every 10% reduction in drag, fuel consumption typically drops by 5-10%. This adds up to real savings during long rides. Aerodynamic fairings and windshields help cut through air more efficiently.

Wind resistance also impacts rider fatigue. Strong airflow pushes against the rider’s body, chest, and helmet. This constant pressure tires riders out on long trips.

The riding position changes how much wind hits the rider. A lower, more forward position reduces the frontal area exposed to wind. Sport bikes use this principle with their aggressive riding posture.

Role of Downforce in Stability

Downforce pushes a motorcycle toward the ground as it moves through air. This force improves tire grip and helps maintain control at high speeds.

Modern sport bikes use aerodynamic wings and fairings to generate downforce. These features redirect airflow to create a pushing force on the front wheel. Better tire contact means improved cornering ability and braking performance.

Too much downforce can make steering harder and reduce top speed. Designers balance downforce with drag to achieve optimal handling. Racing motorcycles use adjustable aerodynamic elements to fine-tune downforce for different tracks.

Wind tunnel testing helps engineers measure downforce levels. They adjust body shapes and add components to create the right amount of downward pressure without adding excessive drag.

Early Approaches to Motorcycle Aerodynamics

Early motorcycles faced significant wind resistance that limited their speed and efficiency. Designers initially overlooked aerodynamics entirely, but as speeds increased, the need for wind-reducing solutions became clear.

Pre-Fairing Motorcycles and Their Limitations

Early 20th century motorcycles were basically bicycles with engines attached. Designers focused on making the mechanical parts work rather than thinking about how air moved around the bike.

These early machines had exposed frames and flat handlebars. Riders sat upright, which created a large surface area facing the wind. This design created massive drag forces that slowed the bikes down and wasted fuel.

The wind hit the rider and bike directly with no protection. Every part of the motorcycle caught air and created resistance. Engine components sat out in the open where wind could push against them.

These limitations became more obvious as engines got more powerful. Bikes could theoretically go faster, but the wind resistance held them back. Riders also got tired from fighting against the wind on longer trips.

The Emergence of Basic Fairings

The first fairings appeared as simple cowlings placed around the front of motorcycles. These early designs actually made the front of the bike bigger rather than smoother. The concept was new and designers were still learning how to work with airflow.

Royal Enfield’s Bullet model offered one of the first factory fairings called the Airflow touring fairing. It included matching streamlining around the front wheel. The design looked modern for its time but proved clunky in practice. It didn’t improve the bike’s handling or balance much.

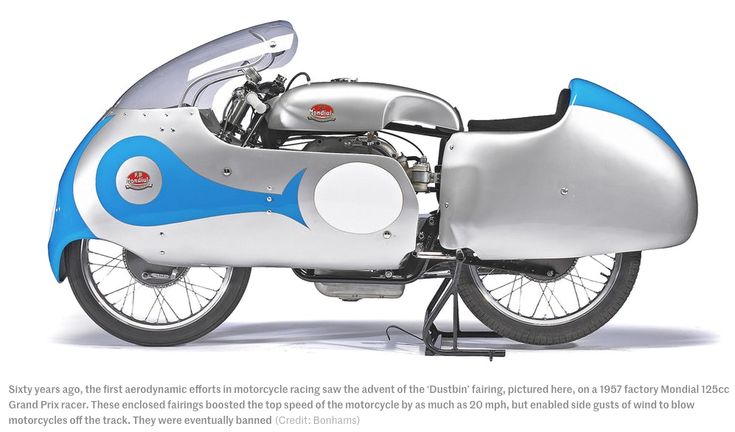

The 1950s brought more serious aerodynamic experiments. Racing teams used “dustbin fairings” that enclosed the entire front of the bike. Moto Guzzi and NSU both tried these designs in Grand Prix racing. They worked to reduce drag but caused dangerous problems in crosswinds. Racing officials banned them because they made bikes unstable.

Influence of Riding Position on Performance

Riders learned that their body position affected how wind hit the motorcycle. An upright position created maximum wind resistance while a tucked position reduced the frontal area significantly.

The 1970s and 1980s saw riders adopt lower, more compact postures. They learned to align their body with the bike’s profile during high-speed runs. This tucked-in position became standard practice in racing.

Designers started creating motorcycles that worked with these new riding positions. They shaped bikes to help riders tuck in behind streamlined fairings. The combination of rider position and bike design created better aerodynamic results than either approach alone.

Technological Advancements in Aerodynamic Testing

Testing methods have transformed how engineers design and improve motorcycle aerodynamics. Wind tunnels provided the first controlled testing environment, while computer simulations and sensor technology now allow teams to analyze airflow with precision that was impossible decades ago.

Introduction of Wind Tunnel Testing

Wind tunnel testing became the first major breakthrough in understanding motorcycle aerodynamics. These facilities use large fans to push air over stationary motorcycles, allowing engineers to study how wind flows around the bike and rider at different speeds.

Early wind tunnels in the 1980s were basic but effective. Engineers could place smoke streams in the airflow to see turbulence patterns and pressure points. They measured drag forces using scales built into the tunnel floor.

Modern wind tunnels offer much more control. Engineers can test motorcycles at speeds over 300 km/h while adjusting variables like wind angle and temperature. Some facilities use rolling roads beneath the bike to simulate real riding conditions. The rider position matters greatly because the pilot contributes significant frontal surface area to the vehicle.

Wind tunnel testing remains valuable today despite newer technology. Teams still use these facilities to verify computer simulations and test physical prototypes before race day.

Computational Fluid Dynamics and Modern Simulation

Computational Fluid Dynamics (CFD) revolutionized aerodynamic development in the 2000s. This software simulates airflow around digital motorcycle models without building physical prototypes. Engineers can test hundreds of design variations in the time it once took to test one.

CFD programs solve complex equations that predict how air molecules behave around surfaces. The software creates detailed maps showing pressure, velocity, and turbulence at every point around the motorcycle. Teams can identify problem areas and optimize shapes before manufacturing parts.

The technology saves both time and money. A single wind tunnel session costs thousands of dollars and requires building physical parts. CFD simulations run on computers for a fraction of the cost. Engineers now use wind tunnels mainly to confirm what their simulations predict.

Sensor and Data-Driven Development

Modern motorcycles carry sensors that measure aerodynamic performance during actual track sessions. Pressure sensors mounted on fairings track air pressure at multiple locations. GPS and accelerometer data shows how aerodynamic changes affect speed and stability through corners.

Teams collect thousands of data points per lap. This information reveals how aerodynamic features perform under real racing conditions rather than controlled testing. Engineers compare this data against CFD predictions to improve their simulation accuracy.

Data-driven development has become standard in professional racing. Teams analyze sensor data between practice sessions to make quick adjustments. This immediate feedback loop helps riders and engineers optimize aerodynamic setup for specific tracks and weather conditions.

Evolution of Motorcycle Fairings and Bodywork

Motorcycle fairings transformed from experimental racing equipment into essential design elements that balance performance with practicality. The journey from early enclosed designs to modern integrated bodywork reflects decades of engineering refinement and regulatory changes.

From Dustbin Fairings to Integrated Designs

The 1950s introduced dustbin fairings as the first serious attempt to reduce drag on racing motorcycles. Moto Guzzi and NSU used these large, rounded enclosures that wrapped around the front wheel and bike.

These fairings created significant aerodynamic benefits but proved dangerous in crosswinds. The instability led to racing bans in the mid-1950s, forcing designers to rethink their approach.

Engineers responded by developing more balanced solutions in the 1970s and 1980s. Streamlined fairings that integrated with the bike’s frame became the new standard. The BMW R100RS in 1976 marked a turning point as the first mass-market sport touring motorcycle with a full fairing as standard equipment.

These integrated designs improved airflow around the bike while maintaining stability at high speeds. Riders adopted tucked-in postures to work with the fairing’s profile, minimizing frontal area and drag.

Adoption of Full, Half, and Tail Fairings

Fairings evolved into three main categories based on coverage area. Full fairings enclose most of the motorcycle from front to tail, offering maximum wind protection and drag reduction.

Half fairings cover the upper portion of the bike, protecting the rider’s torso while leaving the engine more exposed. Quarter fairings provide minimal coverage, typically just around the headlight area.

Tail fairings mount behind the seat and became almost standard on sport bikes with integrated fairing designs. Some extend along the sides and below the saddle to smooth airflow off the rear of the motorcycle.

Touring bikes from Harley-Davidson and Honda’s Gold Wing used fairings as prominent design features. Sport bikes from Ducati, Yamaha, and Honda pushed fairing technology further, creating designs that resembled fighter jets in their aerodynamic sophistication.

Innovations in Aerodynamic Materials

Modern fairings use advanced materials that reduce weight while maintaining strength. Fiberglass became the standard material for aftermarket and custom fairings due to its moldability and repair ease.

ABS plastic dominates production motorcycles because it offers durability, impact resistance, and cost-effective manufacturing. This material allows manufacturers to create complex shapes that optimize airflow.

Carbon fiber entered the market for racing and premium motorcycles. Its high strength-to-weight ratio makes it ideal for performance applications, though the cost limits widespread adoption.

Racing regulations influenced material choices by requiring certain visibility standards and structural requirements. Manufacturers now design fairings that protect engine components during crashes while maintaining aerodynamic efficiency at speed.

Aerodynamics and Performance in Motorcycle Racing

Modern racing motorcycles use advanced aerodynamic features to gain competitive advantages on track. Winglets and active systems generate downforce that improves tire grip, while understanding wake effects helps riders plan overtaking maneuvers at speeds exceeding 300 km/h.

Introduction of Winglets and Active Aero Systems

MotoGP teams introduced winglets in 2015 to address front-end stability issues during hard braking and acceleration. These small wing-shaped devices mount on the motorcycle’s fairing and generate downforce by redirecting airflow.

The first winglets appeared crude but effective. Ducati pioneered their use, mounting multiple small wings on the front fairing. Other manufacturers quickly followed with their own designs.

Key benefits of winglets include:

- Increased front tire grip during acceleration

- Reduced wheelies when exiting corners

- Improved braking stability

- Better high-speed cornering ability

Active aerodynamic systems adjust wing angles based on speed and lean angle. Some designs allow riders to change downforce levels during races through handlebar controls. Regulations now limit winglet size and placement to control costs and maintain safety standards.

Effects of Downforce on Racing Dynamics

Downforce pushes the motorcycle toward the track surface, increasing tire contact pressure without adding weight. This allows riders to brake later, accelerate harder, and maintain higher cornering speeds.

Racing data shows that modern MotoGP bikes generate significant downforce at speeds above 200 km/h. The force increases exponentially with speed, providing maximum benefit on fast sections of race tracks.

Riders adapt their techniques to use downforce effectively. They carry higher corner entry speeds and apply throttle earlier when exiting turns. The added grip from downforce allows them to push harder without losing traction.

Trade-offs exist between downforce and straight-line speed. More downforce creates drag that reduces top speed on long straights. Teams must balance these factors based on each track’s layout.

Drafting, Wake Effects, and Overtaking

A leading motorcycle creates a turbulent wake of disturbed air behind it. Following riders experience reduced air pressure in this zone, which decreases drag and allows higher speeds with the same power output.

Drafting provides a speed advantage of 5-10 km/h on straights. Riders position themselves directly behind competitors to maximize this effect before pulling out to overtake.

The wake also creates challenges for pursuing riders. Turbulent air reduces downforce generation and destabilizes the following motorcycle. Front winglets lose effectiveness in disturbed airflow, making the bike harder to control.

Successful overtaking requires timing and positioning. Riders use the drafting speed boost to draw alongside opponents, then must deal with turbulent air as they pull level. Track sections with long straights followed by heavy braking zones offer the best overtaking opportunities.

Impact of Aerodynamic Evolution on Road Motorcycles

Aerodynamic improvements have transformed road motorcycles by reducing drag and optimizing airflow, which directly affects how bikes perform on everyday roads. These changes have made modern motorcycles faster, more efficient, and easier to control at various speeds.

Improvements in Ride Stability and Handling

Aerodynamic fairings redirect airflow around the rider and bike, which reduces turbulence and improves stability at highway speeds. Wind tunnel testing helped engineers understand how air moves around motorcycles, leading to designs that keep bikes planted on the road.

Modern fairings create smooth air transitions that minimize buffeting. This means riders experience less wind resistance pushing against their body and helmet. The result is reduced fatigue on long rides and better control in crosswinds.

Lower riding positions combined with streamlined bodywork lower the center of gravity. This design change improves cornering ability and makes the bike respond better to steering inputs. Integrated windshields now channel turbulent air over the rider’s head instead of directly into their chest.

Weight distribution improvements work together with aerodynamic shapes to enhance handling. Manufacturers use lightweight materials like carbon fiber and aluminum in aerodynamic components, which reduces overall bike weight while maintaining structural strength. These materials allow for more aggressive aerodynamic designs without adding excess mass that would harm handling.

Enhancements to Fuel Efficiency

Streamlined motorcycle design directly impacts fuel consumption by reducing the energy needed to push through air. Testing shows that a 10% reduction in drag coefficient can improve fuel efficiency by 5-10%, which adds up to significant savings over thousands of miles.

Modern fairings and body panels create smooth surfaces that air can flow over easily. This reduces the engine’s workload at cruising speeds. Riders notice the difference most on highways where air resistance is the main force the engine must overcome.

Adjustable windshields let riders optimize their setup for different riding conditions. Some configurations can yield up to 15% better fuel mileage depending on speed and weather. Even small changes like aerodynamic mirror designs contribute to overall efficiency gains.

Electric motorcycles benefit from these same aerodynamic principles to extend battery range. Every watt of power saved from reduced drag translates directly into additional miles of riding range.

Integration of Racing Technologies into Consumer Bikes

Wind tunnel testing moved from race teams to mainstream motorcycle manufacturers in the 1990s and 2000s. Technologies once reserved for MotoGP bikes now appear on production models. Computational Fluid Dynamics (CFD) software allows engineers to test hundreds of design variations before building physical prototypes.

Sportbikes feature race-derived fairings that create minimal drag while providing rider protection. These designs use the same principles as racing motorcycles but adapt them for street use. Adjustable components let riders fine-tune aerodynamic performance based on their needs.

Active aerodynamics represents the latest racing technology moving to road bikes. Some high-end models now include adjustable wings or spoilers that change position based on speed and lean angle. These systems provide downforce for stability at high speeds while retracting for better efficiency at lower speeds.

Materials and construction techniques from racing have improved durability while maintaining aerodynamic shapes. Carbon fiber components that were once prohibitively expensive now appear on premium consumer motorcycles.

Frequently Asked Questions

Modern motorcycle aerodynamics relies on advances in lightweight materials, sophisticated testing methods, and careful rule-making in racing. These developments have transformed how designers shape bikes for speed, stability, and efficiency.

What advancements in material science have contributed to modern motorcycle aerodynamics?

Carbon fiber has become a primary material for aerodynamic components because it offers high strength with minimal weight. This material allows designers to create complex curved shapes that reduce drag without adding mass to the bike.

Aluminum alloys provide another option for fairings and body panels. These materials are lighter than traditional steel while maintaining structural integrity at high speeds.

Modern composites allow engineers to build thinner body panels that follow precise aerodynamic profiles. The reduced weight improves handling and acceleration while the shapes cut through air more efficiently.

Advanced plastics and resins have made mass production of aerodynamic fairings more affordable. These materials can be molded into smooth, seamless shapes that minimize turbulent airflow.

How do MotoGP tail wings impact the bike’s performance during a race?

MotoGP tail wings generate downforce that pushes the rear tire into the track surface. This increased contact helps prevent wheel spin during acceleration out of corners.

The downforce from tail wings improves traction when riders open the throttle aggressively. Better traction means riders can accelerate harder without losing control.

These wings also help stabilize the bike at high speeds by reducing the tendency for the front wheel to lift. This keeps both tires planted and gives riders more confidence when pushing their bikes to the limit.

What are the aerodynamic benefits of having winglets on racing motorcycles?

Winglets create downforce that increases tire grip during cornering and braking. This additional grip allows riders to carry more speed through turns and brake later into corners.

The aerodynamic load from winglets reduces the likelihood of front-wheel lift during hard acceleration. This keeps the steering responsive and prevents dangerous situations where the front end comes off the ground.

Winglets also help manage airflow around the bike and rider. By directing air in specific patterns, they reduce turbulence that can upset the bike’s stability at racing speeds.

Some winglet designs improve cooling by channeling air toward engine components or brakes. This secondary benefit helps maintain optimal operating temperatures during intense racing conditions.

How has wind tunnel testing influenced the design of contemporary motorcycle fairings?

Wind tunnel testing allows engineers to measure drag forces on different fairing shapes. These measurements provide real data about which designs cut through air most efficiently.

Testing reveals how air flows around body panels and where turbulence forms. Engineers use this information to refine curves and angles until they achieve smooth airflow.

Modern wind tunnels can simulate different riding positions and speeds. This helps designers optimize fairings for real-world conditions rather than just one scenario.

The data from wind tunnel tests shows how small changes in fairing shape affect fuel efficiency. A 10% reduction in drag coefficient can decrease fuel consumption by 5-10%, making these refinements valuable for both racing and street bikes.

In what ways has computational fluid dynamics (CFD) changed the aerodynamic optimization process for motorcycles?

CFD software lets engineers test hundreds of design variations without building physical prototypes. This speeds up development and reduces costs compared to traditional testing methods.

The technology shows exactly how air moves around every surface of the bike. Engineers can see pressure points, turbulent zones, and flow separation in detailed visual maps.

CFD simulations can model conditions that are difficult to recreate in wind tunnels. This includes crosswinds, riding behind other vehicles, and extreme weather scenarios.

Real-time analysis during the design process means engineers can make immediate adjustments. They can test a new idea, see the results, and refine the design within hours instead of weeks.

The combination of CFD with wind tunnel testing provides more accurate results. Engineers verify computer predictions with physical tests, ensuring that only optimized designs move to production.

What regulations govern the size and shape of aerodynamic components in professional motorcycle racing?

MotoGP rules limit the maximum dimensions of fairings and aerodynamic devices. These regulations prevent teams from adding excessive winglets or other components that could create dangerous situations.

Racing organizations restrict where aerodynamic elements can be mounted on the bike. This ensures that wings and other devices don’t interfere with rider safety or create hazards for other competitors.

Technical regulations specify materials that teams can use for aerodynamic components. These rules keep costs manageable and prevent unfair advantages from exotic materials.

Governing bodies regularly update aerodynamic regulations based on safety concerns and competitive balance. Recent years have seen stricter limits on wing sizes after concerns about their effects during crashes.

Race officials inspect bikes before each event to verify compliance with aerodynamic rules. Teams must prove their designs meet specifications or face penalties and required modifications.